Key takeaways:

- Frequency of design collaboration is bolstered with augmented reality.

- One button push sharing of augmented reality experiences comes standard in all versions of PTC’s Creo, Creo View, and Windchill.

- PTC’s augmented reality workflow facilitates secure collaborative design.

Product designers find themselves engrossed in daily discussions of the real world versus the virtual world. As they design new products with 3D virtual digital models in CAD they struggle to imagine what their product ideas would be like in context of the real world. Today, the growing use of Augmented Reality (AR) provides an innovative solution to this problem.

AR allows digital data to be superimposed on the physical world. With today’s web cameras, smart phones, tablets, and wearables users can observe interactive views of the real world environment. AR transforms virtual product geometry data into graphic images that can then be overlaid on those camera views. It is a “marriage” of the virtual and the real worlds.

Figure 1—Augmented Reality: Virtual Image Superimposed Over Real Image (Courtesy of PTC)

Benefits of AR in Product Design

AR bolsters product engineers’ ability to interact with each other as well as others. AR solutions provide a unique opportunity during the design phase of product development when a designer needs to frequently collaborate with a colleague or with other engineers in the supply chain, saving time preparing and sharing documentation. Using AR to share designs requires only a second and the design is sharable instantly around the world.

For example, early in the design phase, the designer may wish to question the placement of a particular product option with a co-designer colleague. That placement may be dependent upon the intended use of the product in the field. The use of AR to view alternatives and observe how they interact with the environment can dramatically improve the quality of feedback and reduce overall response time.

Later during the product’s detailed design phase, the engineer might need to discuss an interference between subassemblies with a component supplier. In this case, with the use of AR the engineer can quickly isolate the problem and allow the supplier to view the exact nature of the issue.

Another powerful AR experience can be established between design engineering and the sales and marketing organizations of the company. Early product design work can be shared using AR, viewing the product in the real environment of a potential customer, offering a realistic impression of the product and its use.

PTC’s AR Workflow

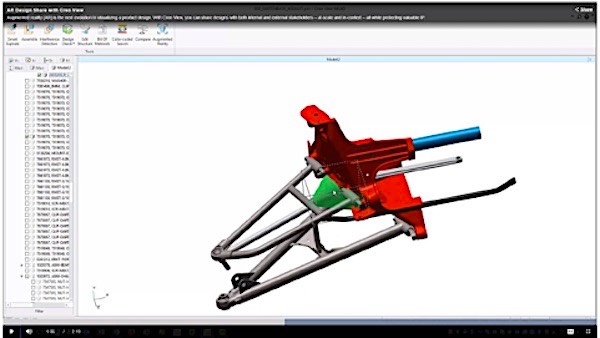

PTC has taken care to provide AR in an easy to use process. The user first opens the model variant they wish to share in Creo Parametric, Creo View, or selects it in Windchill. The user can manipulate the model, potentially hiding or color coding components to highlight an area of interest as seen in Figure 2.

Figure 2—User Selects and Prepares a Model for Collaboration (Courtesy of PTC)

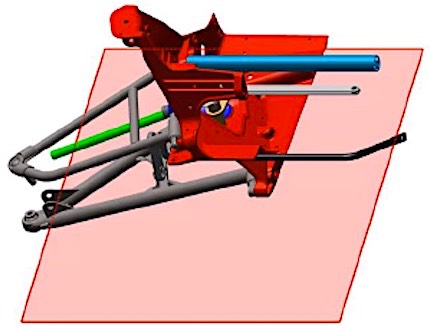

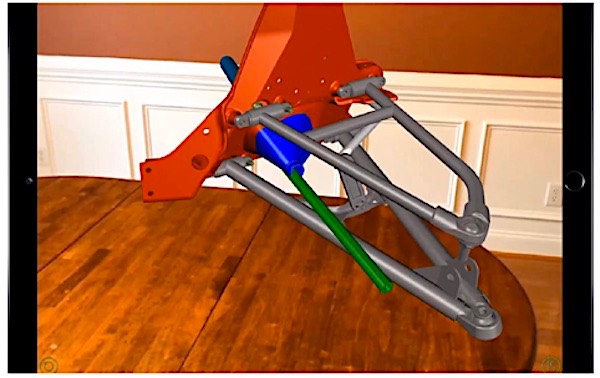

Then, using AR Design Share, the user identifies the spatial target to help place and orient the model in the AR experience. The spatial tracker is a horizontal plane that represents the “floor” for positioning the model (Figure 3). Finally the user publishes the view to the cloud. An email is sent to the collaboration partner with a link to the AR experience in the cloud. When the collaborator opens the link in PTC’s Vuforia View they see the virtual model placed at life-size scale in their environment allowing them to walk around as though they were actually there and scale it for their examination (Figure 4).

Figure 3—User Identifies the Spatial Tracker to Help Orient the Model. (Courtesy of PTC)

Figure 4—The Virtual Model in PTC’s Vuforia View. (Courtesy of PTC)

Secure Collaboration

One of the biggest concerns when collaborating on product data, especially when sharing that data outside the company’s firewall, is security and the protection of intellectual property (IP). PTC’s implementation of AR is notable in that it does not share actual 3D geometric data with the collaboration partners. No physical file is transmitted. Therefore no proprietary constraints and parametric formulas are divulged. Rather a collaborator sees only the graphical representation of the model superimposed into the real environment shown on their device. In addition, the AR experience can be accessed anywhere on mobile devices and at any time since the model is hosted in the cloud.

Further security is supported by the notion that even if a person obtains the link, only the individuals in a viewers list defined by the author of the AR experience can view the model in Vuforia View.

Summary

Augmented reality is rapidly becoming an integrated part of the design workflow enabling instant and in-context collaboration between product design stakeholders regardless of their location. Its ability to merge the virtual data of a product model that is still under development within the real world context offers important benefits to the design team. CIMdata believes PTC’s implementation of AR is both easy to use and offers a much more secure environment than the conventional norm of sharing actual CAD data. In addition, PTC has gone the “extra mile” in prepackaging the AR experience as part of Creo, Creo View, and Windchill at no extra cost, so the cost of entry to the AR experience is nil. PTC’s users will surely benefit.