Key takeaways:

• Wipro has leveraged its expertise in PLM, IoT, analytics, AR, and systems integration to enable digital twins as a promising application of digital thread.

• Wipro enables digital twins for products, processes, and factories at different levels of detail as desired by its customers.

• Wipro has broad expertise in digital twin enablement that has been proven in several industries including aerospace, automotive, consumer goods, retail, and industrial equipment.

Internet of Things (IoT) has helped product and process developers with an unprecedented level of feedback about the performance of their creations in near real-time. The performance feedback can be incorporated into any stage of product and process development, employing a host of innovative closed-loop lifecycle management capabilities. The creativity lies in exploring new and value-adding features and functions for product lifecycle management (PLM) solutions at the intersection of product and process sensor-data, analytics applied to the data, numerical simulation of product and process response, advanced constructs like blockchain, and technologies such as augmented reality (AR).

A concept enabled by closed-loop PLM innovation that is being widely explored in different industries is the digital twin, in which, the value mainly results from relating the virtual and the physical worlds of products and processes. Digital twins allow companies to evaluate product and process decisions based on analytics performed on the digital representations of the products and processes, simulations of the products and processes responses, and the measured data. Products and processes can be visualized as they function in real-time in their environments. Physical assets can be inspected, maintained, and upgraded remotely reducing service costs. Distinct systems and processes can be connected for improved monitoring and troubleshooting, resulting in quick issue resolution. Finally, the performance of complex processes and systems-of-systems can be remotely controlled and optimized.

Developing, implementing and scaling digital twins needs a disciplined approach from executing pilot projects to employing digital twins systematically across different domains of an enterprise. As a first step, one needs a high-level view of the value that the digital twin could bring and how that value could be derived through improved efficiency or through enhanced customer satisfaction or both. Next, one should pick a pilot or demonstrator project that presents the highest potential of delivering the anticipated value with a good chance of successful execution. Broader projects that have the potential to scale across the organization and are applicable to different physical assets and processes should be preferred over very specific digital twins that necessitate deep analysis and could yield high return on investment (ROI) but may prove too complex as a first step. The chosen pilot should be initially focused on a specific area of the business and it must allow demonstration of value. Then, one should work towards realizing the pilot digital twin and focus on the initial ROI objectives by employing an agile and iterative development strategy.

Finally, the project should transition from a pilot to an established solution. This should occur through improvements in performance and leveraging the new resources derived from the digital twin. The constraints originally imposed to control the scope of the pilot digital twin should be removed and the insights from the development and deployment of the digital twin should serve as an initial framework for other areas of the enterprise interested in similar applications. Lessons learned and methodologies formed while producing the pilot should be used to improve the process. Additionally, the digital twin should be assessed based on anticipated benefits such as improvements in yield, quality, efficiency, and robustness, as well as cost reduction. This assessment should lead to further refinement of the digital twin.

Wipro has a long and successful history of providing engineering consulting services, as well as PLM-related systems integration and large-scale data migration. Relatively recently, Wipro has been leveraging its HOLMES offering to develop new and innovative applications for its customers by applying analytics to PLM- and IoT-related data. Wipro HOLMES offers a wide spectrum of advanced analytics capabilities including machine learning, natural language processing, genetic and deep learning algorithms, semantic ontologies, pattern recognition, and knowledge modelling technologies, which as a comprehensive set is very helpful in mining insights and generating innovations across different disciplines.

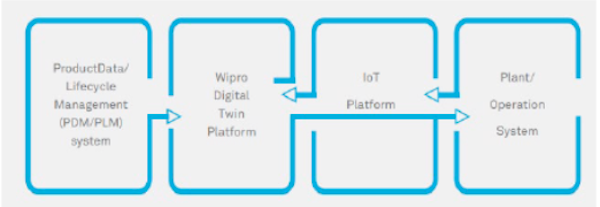

Wipro possesses demonstrated capabilities in delivering custom digital threads *.1 at manufacturing businesses by tying together PLM and other enterprise solutions like ERP and MES, layered with IoT-connectivity so that new and innovative applications can be developed. Wipro offers a digital twin platform (see Figure 1) that bridges the gap between design and operations, creating a closed-loop PLM environment that uses Wipro’s sophisticated asset modeling frameworks to stitch together the two apparently distinct systems in a seamless manner.

Figure 1—Wipro’s Digital Twin Platform (Courtesy of Wipro)

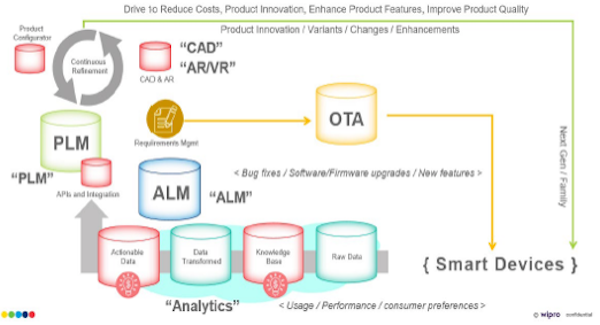

Wipro’s closed-loop PLM architecture for developing digital product twins begins with smart devices or assets from which the sensor-data is picked up (see Figure 2). The raw data goes through a first level of processing according to Wipro’s knowledge base that applies Wipro’s engineering understanding to prepare the data for subsequent transformation based on suitable analytics. The knowledge base applies Wipro’s semantic ontologies and knowledge models to prepare the data for next level machine learning, deep learning, and natural language processing analytics.

Figure 2—Wipro’s Closed-Loop PLM Architecture for Enabling Digital Product Twin

(Courtesy of Wipro)

In the next stage, the actionable information suited for use by PLM and application lifecycle management (ALM) solutions connected to the IoT application is readied. The connection of the IoT application to the PLM and ALM solutions is managed throughs APIs and other forms of integration. For example, the actionable information from the connected assets may drive bug fixes, firmware upgrades, or new features that will be dealt with by the ALM solution and the resulting software updates can be sent back to the assets over the air. On the other hand, the actionable information from the smart assets, which might be useful for continuous product refinement, may be linked to a product reconfiguring system and can leverage advanced simulations or virtual reality (VR) and/or AR, or mixed reality (MR). The redesign cycles can target cost-reduction, innovation of new features and functions, improved quality, adopted variants, or incremental enhancements.

Wipro’s digital process twins focus on operational efficiency, collaboration, and traceability based on detailed process models. Wipro’s process models are set at desired levels of refinement depending upon the complexity needed to be represented. The higher the level of interaction between the process design parameters, the higher the needed level of refinement in the process models. Like in the case of the digital product twins, the digital process twins take the process measurement data and works them through the process knowledge base before applying appropriate analytics to come up with actionable information for refining the process analytical models. The digital process twins are very useful in visualizing the improved efficiency and robustness of the process under consideration.

Wipro’s digital factory twins are mainly geared towards manufacturing asset performance optimization and robustness. The factory twins are closest in their development and use to Wipro’s digital product twins with the main difference being that the redesign cycles are slower while the reconfiguration and software update cycles are faster in comparison. Additionally, the digital factory twin may have more than one manufacturing asset represented by a single digital twin due to the strong interdependence between several assets.

CIMdata has been tracking the development of the concept of digital twin as an application of IoT for many years. Although digital twins can be quite different, depending upon the solution providers enabling their development and the manufacturing businesses leveraging the digital twins, the common theme consists of a digital (or virtual) representation of the system under consideration that is complemented by measurements of the physical system that are communicated to the digital model through IoT. The communication between the physical systems and their virtual representations become more efficient if some form of a digital thread is realized, which usually is understood to be an IoT supported connectivity within PLM, as well as between PLM and other enterprise systems such as ERP and MES.

Finally, if manufacturing businesses want to strategically invest in digital twins then they must plan for a digital transformation that involves the realization of a digital thread and envision digital twins as applications of the digital thread. This vision requires partnership with a company such as Wipro, which has broad and deep expertise not only in deploying a large number of enterprise applications of PLM/ERP/MES, they also have strong capabilities in IoT, analytics, VR, and AR, as well as strategic consulting for companies in many industries. Wipro has demonstrated its expertise in connecting all the elements necessary to build digital threads in manufacturing businesses of different sizes. In addition, Wipro has developed a platform for realizing digital twins for products, processes, and factories and demonstrated their applicability in industries such as aerospace, automotive, consumer goods, retail, and industrial equipment. CIMdata feels that Wipro ranks very high amongst the list of potential partners that a manufacturing business should consider engaging with for realizing digital twins as a part of long-term vision for digital transformation.

*.1 Digital Thread refers to the communication framework that allows a connected data flow and integrated view of an asset’s data (i.e., its Digital Twin) throughout its lifecycle across traditionally siloed functional perspectives.