Key takeaways:

- Altair’s vision to provide systems modeling and simulation for cyber-physical systems is driving portfolio expansion beyond the traditional mechanical domain.

- Altair’s 2017 IPO provided capital investment to aggressively pursue expansion.

- SimSolid technology has the potential to significantly expand the usage of analysis to design engineers as well as to add value to simulation specialists.

- Polliwog, a leader in Korean Mechatronics solutions for LG and Samsung, is the latest acquisition by Altair supporting expansion into electronics/PCB design and analysis.

- The Datawatch acquisition in 2018 is now integrated with the Altair platform and rebranded as KnowledgeWorks to bring Artificial Intelligence (AI) and data analytics directly into play for up-front CAE.

- Altair predicts CAE specialists will become leaders in the application of data analytics throughout the product development lifecycle.

Products in all industries are becoming more and more dependent on electronics and software functionality including being connected as “smart” Internet of Things (IoT) devices. The design and development of complex cyber-physical systems requires well integrated capabilities for cross-disciplinary mechatronics simulation, analysis, and design optimization supported by advanced data analytics. Altair continues to round out its systems modeling and simulation portfolio to enable their vision of model-based and simulation-driven design.1

As part of this vision and product strategy, Altair’s KnowledgeWorks solution has been developed from the 2018 acquisition of Datawatch. The SimSolid technology was also acquired in the latter part of 2018 and this solution is now integrated with the HyperWorks platform. And at the recent 2019 Altair Global Advanced Technology Conference (ATC) event, the acquisition of Polliwog was also formally announced.

Altair’s Vision for Engineering

Altair has been a recognized leader in mechanical design optimization with the OptiStruct technology and the application of high-performance computing (HPC) for state-of-the-art multi-physics simulation. The robust exploration of potential design spaces to create new product innovations continues to drive the need for advanced modeling and simulation solutions leveraging and supported by affordable and scalable cloud solutions combined with HPC.

Altair’s position is that simulation and modeling should drive 3D design rather than just be a verification of a robust design. Mr. Jim Scapa, CEO and co-founder, summed up this vision as transforming engineering decisions from the very beginning of concept development. Altair has pursued this vision for over two decades and has recently expanded their application suite to include new technologies for rapid analysis of CAD geometry including assemblies (SimSolid), advanced data analytics (Datawatch), and PCB/electronics simulation and design (Polliwog), and is hosting their applications in the cloud via the Altair 365 platform.

Altair is focused on integrating advanced data analytics to deliver on their vision of transforming engineering decision making and believes that the use of AI/machine learning technologies will have a game changing impact on the way that product development and manufacturing are done.

IPO Raised Capital for Investments in Technology and Skills

In 2017 Altair raised capital by executing an initial public offering of company shares on the NASDAQ market with symbol ALTR. The capital raised has enabled Altair to make a number of strategic acquisitions over the past two years including SimSolid, Datawatch, and Polliwog. Furthermore, they invested in developing a vendor agnostic cloud platform including a patented “Rapid Scaling Algorithm” and also invested in an improved, consistent user experience for the HyperWorks platform and suite of applications.

The recently acquired SimSolid technology is quite unusual and intriguing. Based on a set of a proprietary algorithms developed by Dr. Victor Apanovich, it enables certain types of simulation models, including even reasonably large and full featured CAD assemblies, to be rapidly modeled and solved with the complexity of the finite element model preparation, meshing, and solving largely hidden from the user. While initially targeted more at design engineers who are not experts in FEA and CAE, because it is so much easier to learn and use, the extremely fast and almost interactive computational solver has led to early adoption even by traditional CAE simulation specialists. However, Altair expects that with SimSolid technology integrated with its other design-oriented tools, more and more design engineers will get comfortable doing their own baseline CAE analyses before they release a part to a simulation expert for more detailed analysis and validation (as required) or to manufacturing engineering. It should be noted that SimSolid works best on materials with well-known and homogenous or continuous properties—so it is not yet appropriate for composites or other types of advanced hybrid materials. Altair customer’s like Don-Bur are praising the speed improvements SimSolid is delivering.2

2019 ATC Event in Detroit

The annual global Altair Technology Conference (ATC) was recently held in Detroit with over 1,000 registrations and a full venue at the MGM Resort. Mr. Scapa stated that sales in 2018 were nearly $400M, and their growth is strong and steady.

Mr. Scapa stated that more and more of their customers are applying OptiStruct in concert with the HyperWorks suite of S&A applications to address their complex engineering processes. Optimization, analytics, and the need for computing speed were emphasized with customer examples from across different industries.

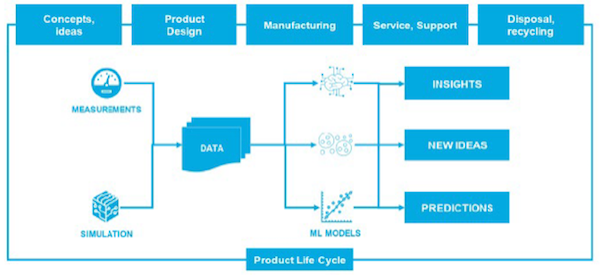

A fascinating discussion and associated market forecast “AI and the Future of Product Lifecycles” was made by Mr. Mamdouh Refaat, Chief Data Scientist, as he discussed AI and data science applications to CAE. He believes that CAE analysts will become simulation data scientists faster than any other professional role because they already understand the way to apply CAE tools with HPC to solve complex analyses. He presented Figure 1 when summarizing the artificial intelligence promise. He also contends that the IoT big data analytics process is very similar in nature to performing simulations—preparation, constructing the model (data grooming), executing the model (learning), and post-processing. Combining simulation with field data will improve the product development process as well in service operations.

Figure 1—The AI Promise (Courtesy of Altair)

CIMdata also had the opportunity to interview several of Altair’s senior technical leads on their plans and goals: Mr. Sam Mahalingam, Mr. Uwe Schramm, Mr. Jeff Brennan, and Mr. James Dagg. It was satisfying to see the passion and consistency of overall vision and purpose from these senior executives, even though each is focused on different aspects of the ultimate solution—simulation lifecycle management/IDE services, simulation solvers, cloud expansions, and consistent user experience. From their different points of view, they discussed the “Challenge Champion Model” which allows continuous training of the data sets/models as new data (i.e. experience) is discovered. Two additional Altair data scientist leaders, Mr. Christian Kehrer and Ms. Fatma Kocer-Poyraz, explained the need for closed-loop learning throughout the product lifecycle. They have a clear definition of Digital Twin—a math based representation of a product throughout its life. Their vision is that a digital twin is organic, and it must continuously evolve as experiences are discovered from products and systems operating in real world user environments using field data to make the digital model representation higher and higher fidelity as those experiences are discovered.

In the age of IoT and Industry 4.0 where data is collected continuously from products in service, the digital twin simulation models can continuously be refined to accurately predict the ongoing performance of a product. Field upgrades and maintenance can be improved after product introduction with insights harvested using this digital twin capability. Figure 2 shows the digital twin throughout a products life using Altair’s Connect. Altair is assembling a portfolio of applications to enable such lifecycle improvements based on simulation, optimization and analytics. Smart IoT systems obviously have a large amount of electronics content and so Altair took action to find a solution for EDA/ PCB engineering tools. The Polliwog acquisition announced October 10th should provide a more comprehensive bridging of the disciplines involved in the systems engineering process.

Figure 2—Digital and Physical Data Connected (Courtesy of Altair)

CIMdata looks forward to seeing how connecting the digital twin and applying optimization throughout and across the mechanical and electronics domains can be improved now that Altair owns a proven PCB modeling and design tool. Altair technology principals clearly appear to understand the power that AI/machine learning/deep learning can bring to engineering decision making. They recognize that selling value-added engineering solutions is more compelling than selling merely a CAE platform and this is what drives their acquisitions. These new capabilities will be essential to their customers in achieving value from investments in digital engineering and digital twin initiatives in the years ahead.

Altair’s flexible licensing model across the desktop, the cloud, and HPC is designed to make the initial use and expansion of Altair technology straightforward and cost effective for companies of all sizes, especially for small to mid-size organizations that have limited IT resources and expertise. Given their simulation and HPC track record, CIMdata believes that Altair has a well architected solution set for the flexible use of the engineering technologies they provide. And based on the cross section of industries represented at the ATC, it is indeed encouraging that they are expanding their customer base globally and beyond their historical base of the automotive/vehicle industry.

Conclusion

CIMdata believes that the Altair solutions and their flexible licensing model offers an appealing choice for any discrete manufacturing company who has the need to improve decision making through product concept, design, and virtual validation. They have expanded their proven HyperWorks platform for simulation modeling, analysis, and data management to utilize the cloud as well as HPC and provided an integrated data analytics capability. Investment in a modern and consistent user interface across all the HyperWorks applications should greatly improve ease of use for a broader range of users as well as a reduced learning curve for new adopters. And the SimSolid technology has the potential to be a major factor in the long time quest towards the democratization of simulation.

We expect to see more from Altair as the simulation and data analytics capabilities expand to include decision making across the entire product lifecycle. Altair has now positioned itself to model, simulate, and analyze mechatronics products and their connection as smart IoT devices and services—be they robots, cars, or home appliances/gadgets.

1 Travel and/or other expenses related to this commentary were provided by Altair.

2 See Don-Bur video: https://www.altair.com/resource/simsolid-drives-down-analysis-time-at-don-bur