Key takeaways:

- In the last 5 to 10 years companies have experienced a dramatic technology and business transformation with the advent of connected products, digital factories, products as services, and Industry 4.0, forcing them to move from static supply chains to dynamic global value networks. Accurate and timely product lifecycle information is essential to bring those innovative product ideas to life.

- The walls and disparate data silos between PLM and other enterprise business processes must be eliminated. Oracle’s single cloud platform and an enterprise product record help eliminate these silos, providing the velocity and resiliency needed to support today’s complex business transformations.

- Oracle Product Hub Cloud provides a single data source that weaves the digital thread together seamlessly from multiple heterogeneous data sources to support the product lifecycle from idea through commercialization.

- Customers in a wide range of industries are already seeing great value from using Oracle Product Hub Cloud to support their lifecycle processes.

Introduction

Over the last several decades product companies began to rely more and more on their supply chain partners to help them deliver value in the products they sold. Many supply chains were initially more local or regional but several trends helped these companies evolve their supply chains into global value chains. Today’s products are increasingly smart and connected, adding even more complex requirements. As new products go from idea to commercialization, deployment, and lifecycle support, product companies are realizing they must capture a digital thread of information across that span as a pre-requisite to providing lifecycle support.

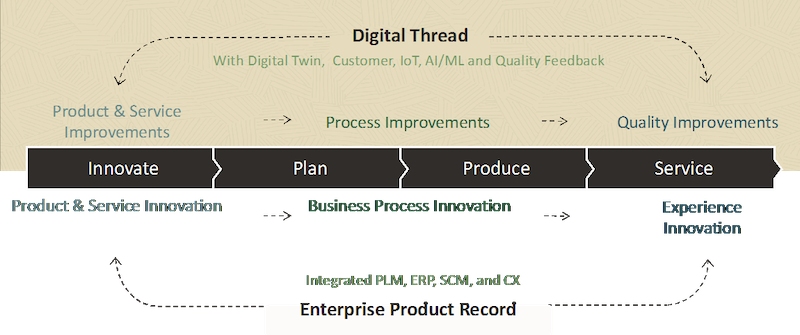

The digital thread capabilities of the Oracle PLM Cloud, termed their enterprise product record, span this full lifecycle and provide a rich information set to support a wide range of industries and use cases. This commentary provides more information on how their digital thread capabilities are being delivered to customers today. 1

From Supply Chains to Global Value Chains

Product companies across a wide range of industries have long relied on their supply chains for key components and subsystems. Product lifecycles were long enough to develop long-term strategic relationships with key suppliers, who increasingly provided more and more value to the firms at the top of the chain. Their competitors were mainly local or regional, drawing on the same set of supply chain resources.

Today, product companies draw global competition, often from firms that are competing on cost or delivery times, causing them to act in response. Product lifecycles continue to shrink, often due to competitive pressures, putting companies under pressure to bring more and higher quality products to market faster and faster. To compete globally, they need to draw on new supply chain partners who can help them meet increasing customer and market demands, increasing supply chain complexity. In this complex environment companies have to squeeze out any non-value added time and resources to have a chance at market success.

Over the last twenty years, product companies have looked to a range of digital technologies to help streamline the product development and commercialization processes from idea through life, a concept that CIMdata and others term product lifecycle management (PLM). CIMdata defines PLM as a strategic business approach that applies a consistent set of business solutions in support of the collaborative creation, management, dissemination, and use of product definition information across the extended enterprise. PLM spans from product concept through life and integrates people, processes, business systems, and information. In today’s market, these capabilities are increasingly delivered by a product innovation platform that supports lifecycle activities across more business functions than just engineering and manufacturing. The platform approach enables the product information backbone for a company and its extended enterprise, as shown in Figure 1. It enables a set of lifecycle processes and incorporates best practices, methods, and processes. It also includes a set of modeling and simulation capabilities and lifecycle optimization techniques that span multiple disciplines.

Figure 1―CIMdata's Product Innovation Platform

To date, most PLM strategies have relied on a range of on-premise solutions to manage data and define collaborative processes, author new intellectual property, test out new ideas, and a host of other tasks to support the product lifecycle. This heterogeneous set of fragmented solutions can be difficult to support to say the least. Now add the complexity of moving solutions to the cloud, which is creating a perfect storm for many companies. Which meaning of the word “perfect” applies depends on your point of view. Unfortunately, for many companies that perfect storm is wreaking havoc on their ability to remain competitive. And it is happening at a time when capturing accurate and complete information about the evolving product, its manufacture, deployment, and support are becoming essential to support new business models, and ensure that next generation products continue to delight their customers

Building the Digital Thread

CIMdata has talked about capturing this type of information since the emergence of the PLM concept twenty years ago, which we referred to as the bill of information (BoI). Today we refer to that same idea as the digital thread, and it remains core to successful PLM strategies and implementations. While PLM often focuses on design and engineering, the concept of PLM also must enable multi-disciplinary lifecycle optimization at its core. This is well beyond just traditional computer-aided engineering (CAE), and must consider all enterprise processes as suggested in Figure 1. Engineering decisions must be balanced with cost, quality, and profitability considerations to ensure the right product is delivered at the right time for the right markets. Making these decisions requires synthesizing engineering data with data from other enterprise applications to understand the relationships between business and technical key process indicators.

It is this broader definition of the digital thread that must be supported today. CIMdata defines the digital thread as the communication framework that allows a connected data flow and integrated view of an asset’s data (i.e., its Digital Twin) throughout its lifecycle across traditionally siloed functional perspectives. The digital thread is woven from idea through life. The choice of the term “woven” was explicit because while single providers may claim to support every aspect of an organization and its business, the real world is most often a brownfield. Companies have many legacy applications, some commercial and many often custom built in-house. Their systems also have to handle significant data from outside the enterprise. All of this information can be valuable and can be imported, as long as it is added under the right quality control and in the appropriate context.

PLM is focused on building the right intellectual property to support manufacturing and other downstream functions, like maintenance and service, while also enabling traceability throughout the lifecycle. For manufacturing, companies rely on enterprise resource planning (ERP), manufacturing execution systems (MES), and other enterprise applications, adding more attributes and information to the evolving digital thread. For example, information can come from many sources, including PLM, ERP, legacy systems, supply chain partner solutions, commerce solutions, and catalog solutions.

The digital thread must evolve to more explicitly include manufacturing and commercialization information that gets the product to the customer, where usage life begins. While expanding the digital thread with this new information is essential, significant challenges must be addressed. Data for these areas is fragmented across multiple systems and trading partners. Developing and maintaining the integration points to manage the required information can significantly raise IT costs and complexity. There is no core governance process across the trading partners to ensure accuracy and timeliness. Poor data quality is often the inevitable result.

Oracle’s Enterprise Product Record, their digital thread, spans the product lifecycle from idea through life and provides access to significant lifecycle information. This commentary focuses on Oracle’s end-to-end approach and how it is being delivered to customers today.

Oracle’s Enterprise Product Record

Oracle has offered product lifecycle solutions for over twenty years, but they significantly expanded their commitment to the segment and renewed its PLM journey by acquiring Agile Software in 2007, one of many segment-leading companies Oracle acquired during that period. Oracle saw service-oriented architecture (SOA) as the way forward for their complex portfolio, dubbed Fusion by Oracle. One early Fusion application was the Oracle Product Hub which focused on the commercialization process, a natural fit with the supply chain emphasis of Oracle Agile. The lessons learned from the Agile PLM solution and their other applications helped guide their development, first in Fusion and then for the cloud. This provided the seed to develop their enterprise product record, which spans from ideation in Oracle Innovation Management Cloud, through commercialization in Oracle Product Hub Cloud. Today, Oracle Product Hub Cloud is the enterprise product master foundation for all of their ERP, supply chain management (SCM), and customer experience (CX) cloud applications focused around the commercialization process.

Oracle PLM Cloud, shown in Figure 2, is termed their PLM 4.0 platform, referring to a fourth generation of PLM-enabling solutions. Oracle saw 1990s solutions as CAD-centric, evolving in the 2000s to focus on engineering. In the 2010s, Oracle focused on product launch and today they believe their “future-ready connected PLM” can help connect supply chains and their customers. Oracle PLM Cloud was designed to span from idea through commercialization. Today, Oracle believes their PLM solution enables connected and resilient supply chains designed to span the entire product lifecycle.

Figure 2―Oracle's Solution for Business Model Innovation (Courtesy of Oracle)

While Oracle Corporation does offer a full suite of cloud applications, it recognizes the heterogenous nature of today’s IT environments. To support these complex environments, Oracle invested heavily in product data quality and other master data management (MDM) related initiatives and technologies that are brought to bear in Oracle’s applications. Oracle believes that their rigor in MDM supported by their extensive toolset helps ensure this enhanced digital thread has the right information in the right context―a semantic representation of the enterprise product record―to tie all of those things together.

Integration is the communication mechanism. Oracle can support a wide range of integration scenarios to bring in the necessary data, the knowledge of the product and the necessary logic resides in the product record. Oracle Integration Cloud is their core offering, but the actual integration can be done by other offerings, from Oracle and other providers. In this way, many other enterprise applications and processes are contributing to the product record and enhancing the product master data. Oracle believes their solutions will help them “rewind the past,” replaying the digital thread backwards and forwards to support what-if scenarios. This is a good example of the multi-disciplinary optimization highlighted in CIMdata’s Product Innovation Platform definition shown in Figure 1.

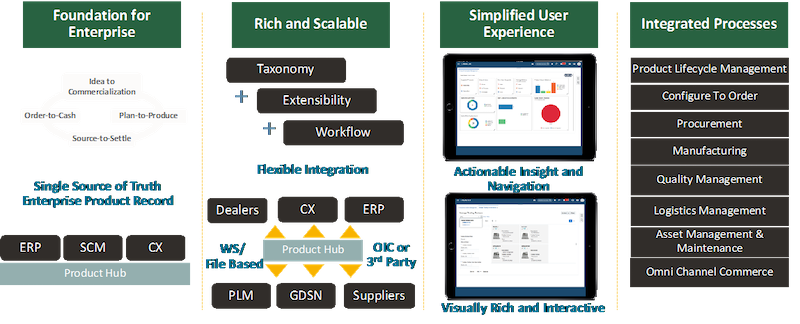

The core elements of the Oracle Product Hub Cloud are shown in Error! Reference source not found.. This solution is Oracle’s “single source of truth” spanning the full product lifecycle. It integrates a range of processes, which may be supported by Oracle solutions or those from other providers. It provides an end-to-end governance process to help enforce business rules and policies, while providing a complete audit trail. The Oracle Product Hub Cloud also helps reduce the need for complex point-to-point integrations, acting, as its name implies, as a hub that helps streamline data sharing across the extended enterprise.

CIMdata believes that Oracle is well positioned to support these digital thread needs because of their broad applications legacy. To build these new solutions, Oracle leveraged knowledge from their PLM, ERP, SCM, E-Business suite, PeopleSoft, Siebel, and JD Edwards teams. This gives them a strong understanding of the processes and necessary data, from New Product Development and Introduction and spanning well beyond the engineering domain. This has allowed them to build the necessary connections to support heterogeneous IT environments, defining and capturing the required data elements powered by data governance processes to help ensure a complete digital thread.

Figure 3―Oracle Product Hub Cloud (Courtesy of Oracle)

To help improve their customers’ time to value, Oracle built out some important Oracle Product Hub Cloud use cases to help with common scenarios. For example, Oracle created industry-focused capabilities to support consolidation/migration, data governance, and business intelligence for industries like medical devices, retail, distribution, and manufacturing. Oracle claims their offerings also support additional use cases in customer experience, procurement, supply chain, and for other PLM uses.

Oracle recognizes that each customer has their own unique journey to the cloud. Some want to use Oracle Product Hub Cloud to best leverage their existing investments in on-premise offerings, providing that single source of truth. This can be a first step toward a hybrid environment where more and more workload moves to the cloud until the transformation is complete. CIMdata has seen Oracle present this approach at their user events for the last several years and, based on audience reaction, it seems to resonate with their customers.

Customers of Oracle Product Hub Cloud are seeing great value from the solution today. For example, a major provider of natural gas compression services in the United States needed a cloud-based solution to help manage, organize, and clean up their fragmented product data. The company believes Oracle Product Hub Cloud will establish a foundation for broader adoption of cloud-based solutions in the company. A global leader in the floorcare industry used Oracle Product Hub Cloud to help transform their product data across multiple business systems supporting the standardization of their business processes across their global operations. One of the world’s largest padlock manufacturers uses Oracle Product Hub Cloud to help manage their new product introduction and commercialization process. And finally, a global high-tech provider of data storage devices and solutions uses Oracle Product Hub Cloud to manage centralized product master data across their three divisions as part of their ERP transformation on the cloud.

All of these companies, and many others, have chosen Oracle Product Hub Cloud to help them manage their product information across the lifecycle from idea through life, a capability that is core to the enterprise product record, the data structure underlying Oracle PLM Cloud and one of its key elements, Oracle Product Hub Cloud.

Conclusion

In response to global trends like Industry 4.0 and smart connected devices, companies are moving from static supply chains to dynamic global value networks. Accurate and timely product lifecycle information is essential to bring their innovative product ideas to life. Oracle has taken a different approach by rewriting its ERP, PLM, SCM, customer experience (CX), and IoT applications on a unified cloud platform. With this approach, Oracle is providing a single enterprise record that spans all enterprise cloud applications, creating an expansive digital thread that runs thru the entire product lifecycle. Oracle believes that when customers start with implementing Oracle Product Hub Cloud as a foundational component they can phase in other cloud solutions on the same platform without requiring any additional integrations. Customers from a range of industries are already seeing great value from using Oracle Product Hub Cloud to support their lifecycle processes. It also helps them better tie into Oracle’s overall cloud strategy and many offerings speeding their cloud journey and digital transformation, essential for companies seeking market success in our increasingly smart, connected world. CIMdata was impressed by the range of use cases supported across the customers reviewed and looks forward to learning more about the cloud journeys of Oracle’s many other PLM customers.

1 Research for this commentary was partially supported by Oracle