Key takeaways:

- Siemens Digital Industries Software’s Capital expansion brings together design trade-offs of electrical systems and embedded software.

- With the use of Capital, Model-Based Systems Engineering now has streamlined access to wiring, embedded software, and electronic details.

- Viewing and annotating mechanical, electrical, electronic, and embedded software design in their native systems, including artifacts from the other disciplines, is no longer a manual exercise fraught with complex interdisciplinary configuration problems.

- Capital’s use of Teamcenter Product Configurator is further evidence that Siemens Digital Industries Software is providing an ecosystem enabling a Comprehensive Digital Twin across the extended enterprise.

Silos of information and data exist due to the existence of varied information technologies, numerous investment cycles, various organizational structures and responsibilities, differences in education, and wide-ranging knowledge and wisdom management practices.1 To be successful, PLM platforms must enable better Systems Engineering (SE) across the complete product lifecycle. The right SE practice can help engineers see each disciplines’ contextual point of view ultimately leading to better decision making. Today, Digital Twins, composed of design, test results, customer insights, and environmental conditions, are the cornerstone of a company’s digitalization ecosystem.2

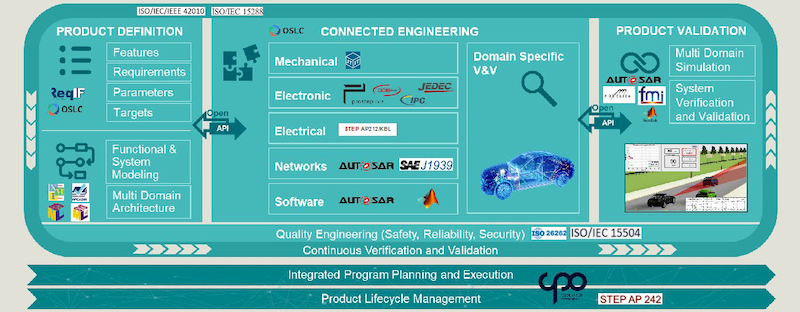

Supporting complex decisions during product development, manufacturing, and operations is a systems problem. The problem is to assure that the requirements are fulfilled and not violated throughout the life of a product. An important issue is how the system’s defining constraints are maintained, adhered to, and managed as the product moves through its lifecycle—from concept through and including the end of its useful life. This requires the concept of a digital thread of the requirements and other product data tied to an ever-changing digital twin. To accomplish this, consistent product configuration across the disciplines is also required as shown in Figure 1.

Figure 1—Supporting Collaboration Across Functional Domains (Courtesy of Siemens)

At the 2020 Realize Live event Siemens Digital Industries Software (Siemens) announced product features and progress on their SE framework where different disciplines can collaborate more effectively, providing a robust Model-Based Systems Engineering (MBSE) ecosystem. Collaboration improves as organizations embrace MBSE if that view is well integrated with discipline-specific views. Siemens’ Capital solution delivers MBSE benefits for enterprises in all industries where traversing the silos between electrical, electronic, software, mechanical, and even systems engineering disciplines is more challenging as product and service complexities expand.

Siemens has a product configurator service, which was originally developed as Teamcenter service, that is now available to Capital users. This is exactly what the digital thread requires—consistent product configuration across the disciplines throughout a product’s life.

Furthermore, there is a growing value that electrical and electronic systems and their associated embedded software are bringing to products, often after the original product is mass produced. For example, most consumers now expect to receive upgrades during a product’s lifecycle. With the increased complexity of these integrated systems and their upgrades after sales, getting it right is getting harder—hence the need for new solutions to support and enable all engineering disciplines.

Systems Engineering as its own discipline has existed for decades. Computer-based SE (i.e., MBSE) improves product robustness as it allows engineers to see and potentially optimize more interactions amongst defined requirements and solutions before a product is produced, even across engineering disciplines.

Siemens has built a rather comprehensive set of applications across several disciplines ranging from mechanical to electrical to manufacturing to embedded software. Seeing these disciplines working together is no longer limited by tools and file sharing. The following describes a few examples of the synergies Siemens is creating.

Capital brings electrical and harness engineering, as well as embedded software development, into the systems design realm earlier. Improving systems designs for the operational lifecycle in addition to manufacturing. Considerations for feature partitioning are getting easier while understanding service and manufacturing constraints. Throughout the 2020 Realize Live Event, Siemens representatives and early adopters from GM and Northrop Grumman discussed their progress toward improving systems by considering harness layout, and sustainment and service needs earlier in their product design processes.

Figure 2—Systems Architecture Optimization (Courtesy of Siemens)

Car harness design, which supports a broad family of products within a platform, is a challenge for mass production. It gets more complicated when making the Electrical/Electronic (E/E) system future proof to provide product upgrades while in the customer’s possession. Aircraft are maintained over decades and the sustainment activities of operational fleets require service manuals and related practices derived from the E/E design and assembly. As shown in Figure 2, Capital is expanding into the early architecture and the post manufacturing domains with their new features that support this broader lifecycle.

Figure 3—Teamcenter Product Configurator in the Capital Solution (Courtesy of Siemens)

Forming the comprehensive digital twin of a product at any time requires a consistent and powerful configurator. One that creates a future usage context and one that drives design assemblies wherever they occur during product development and service. One Product Configurator service enables consistent configuration from product inception to end of life. Capital is now using Product Configurator and Workflow from Teamcenter as shown in Figure 3.

Capital’s Software Designer (Figure 4) is another part of Siemens’ Xcelerator portfolio of solutions addressing the needs of compliance and seamless integration.

Figure 4—Capital Software Designer (Courtesy of Siemens)

Finally, modern electrical and electronic applications in a PLM platform must start integrated and stay integrated. This means bridging the information silo’s consistently and continuously as shown in Figure 5. Automatic and controlled exchanges are needed to manage complexities in product development and operations. Effectively using another discipline’s data forms a Comprehensive Digital Twin.

Figure 5—MBSE Integrating Across the Information Silos (Courtesy of Siemens)

Using product requirements confidently in each discipline contributes to the same Comprehensive Digital Twin. This enables robust requirement traceability in each discipline’s context. The same product requirement is referenced in different views with traceability in one place. This is a needed improvement over file based, manually updated, copies of requirements traceability matrices. Model Based Engineering including requirements traceability is becoming a reality.

Siemens’ vision and strategy are advancements on the way to Model-Based Engineering. By supporting proven standards, an ability to easily integrate across the extended enterprise is realized—open ecosystems allowing external tools and data sources to be seamlessly integrated.

Over the last several years, Systems Engineering has improved with the power of computing, allowing faster exploration of solutions and safety margins of candidate designs. Computing speeds and simulation accuracies continue to advance. But with distributed computing came distributed data, which can be difficult to manage. Additionally, engineers need stable, readily accessible configurations as baselines to help manage their decisions. A common product configuration engine used across mechanical and electrical disciplines is a cornerstone of modern PLM platforms.

Siemens has developed and acquired many of the tools engineers need. Their intelligently integrated ecosystem is realizing a comprehensive product development environment, what a progressive PLM platform should enable. Siemens’ Capital, Polarion, MBSE, and Product Configurator integration is evidence of their holistic and end-to-end PLM ecosystem, branded as the Xcelerator portfolio of solutions.

Capital is the comprehensive Electrical/Electronic Systems development solution within Xcelerator. This solution portfolio includes direct support of Systems, Electrical, Networks, and Software development—all technologies core to today’s complex products. Transparency across discipline silos improves product decisions during development, manufacturing, and operations. Expansion of Siemens’ Capital solution brings new levels of integration for holistic engineering. Systems engineers are more empowered to help the software, mechanical, and electrical disciplines understand their operating context, which in turn improves the speed and accuracy of decisions. With this solution customers will see improved time to market as all engineers together make better decisions faster.

Siemens’ Xcelerator portfolio, and especially Capital’s comprehensive E/E capabilities, further differentiates Siemens in the PLM market. CIMdata recommends that companies should consider the Xcelerator portfolio of solutions, especially Capital, when evaluating and/or migrating current and future E/E solutions. As computers are pervasive in products today and tomorrow, a comprehensive, integrated, and multi-disciplinary product development environment is essential.

1 Bridging Information Silos to Improve Decision Making, CIMdata Webinar presented 10 September 2020.

2 Research for this paper was partially funded by Siemens Digital Industries Software