Key takeaways:

- Supporting logistics of complex products is a massive undertaking that benefits from the data and process management provided by modern Product Lifecycle Management (PLM) capabilities.

- The U.S. Navy is embarking on a major modernization driven by digital transformation that will update and streamline its fleet readiness program, replacing its largely paper-based legacy.

- The U.S. Navy requires a secure cloud-enabled environment as the foundation of a commercial off-the-shelf (COTS) - Software as a Service (SaaS) strategy to achieve the global access required to support its widely distributed operations and logistics.

- The U.S. Navy has selected PTC’s Windchill to be the platform for Model Based Product Support.

Fleets of any type—ships, aircraft, trucks, and others—create certain logistical issues. They are constantly in use all over the world, operating in inclement weather and contested environments. They are continually repaired away from their base of operations, and the configuration of each vehicle in the fleet is different (see Figure 1), leading to difficulty in understanding what can be repaired or replaced. The more complex the fleet, the more stubborn those issues become and the more costly the resources required for support. The fleet needs to be maintained and upgraded on a regular basis and sometimes in emergency situations.3

The U.S. Navy seagoing fleet is large (300+ active and reserve ships and Expeditionary Forces), globally dispersed, and often operates in harsh, unforgiving environments. Ships that comprise the Navy fleet include the largest, most complex moving structures in the world—and no two are identical. Thousands of sailors are involved in their day-to-day operation and essentially rely on the ships for their life support—which adds another critical dimension to each ship’s complexity. Keeping the fleet ready to serve in a diverse set of capacities is the role of the Warfighting Capability and Digital Readiness Services division within the Naval Sea Systems Command (NAVSEA03R). This organization plans for and directs the maintenance of all elements of the Navy fleet.

Currently, naval logistical planning and execution is based on a broad mix of documents and other information in a multitude of formats. This information is spread across many systems and information repositories, some of which are out of date and difficult to access and maintain. Much of the current data is paper-based. What electronic data exists is maintained in many formats and stored on different, often old, devices, all under the control of different parts of the logistics organization. A single index, data source, or digital thread of data that could be used to effectively support logistics does not exist, so gathering the information required to support a logistical exercise is a daunting, time-consuming task. The Navy recognizes that they need to improve this situation along a number of axes—lifecycle costs, operational availability, data accessibility, data integrity and security, data reuse vs. duplication, support for collaboration, support for new and streamlined work processes, maintaining an up-to-date repository of in-service configurations, system sustainability, and a multitude of other factors. As Mr. Paul Koester, Program Manager for Model Based Product Support, NAVSEA03R said “…it’s a seismic shift in the way the Navy manages its product lines and represents a revolutionary change not only for how programs operate, but for the Navy workforce in general…for the chief goal is to provide the warfighter with the capability to model, predict, and optimize its investment in logistics resources based on the ability to rapidly understand changes in mission requirements, and being able to model and optimize logistics resources to meet those changing requirements.”

Figure 1—Large Variety of Ship Types Maintained (Image courtesy of U.S. Navy

At this time, the Navy logistics organization, along with other parts of the Department of Defense (DoD), has embarked on modernization efforts based on modern digital transformation strategies. The expectation is that digitally transforming how naval logistics is supported will provide better information (particularly content-rich 3D data which is difficult to leverage in the current environment) that will improve fleet readiness, streamline operations, reduce support and maintenance costs, decrease errors, and reduce IT costs. CIMdata’s experience supporting digital transformations in many industries indicates that these are very achievable goals, given a good strategy and effective execution.

Embarking on a digital transformation is a journey. Digital transformation is a complex, time-consuming process requiring a vision, strategy, and roadmap to plan, select, and implement appropriate processes and technologies to fulfill the vision and achieve success. Effective, timely implementation of capabilities and processes that support the vision and strategy is also of paramount importance. Because of the breadth of impact across an extended enterprise, executive leadership is essential to achieving goals and success. In the Navy’s case, this leadership is provided by Mr. Thomas Murphy, Deputy Director of NAVSEA03R The Navy has named their logistics digital transformation project Model Based Product Support (MBPS).

A conceptual fallacy that persists in many organizations is that digital transformations in general, and product lifecycle management (PLM) in particular, provide benefits only to product developers (e.g., design engineers). Experience working with organizations who have properly gone through a digital transformation shows otherwise. Often the largest benefits of a digital transformation come from its impacts on the people who are consuming the product’s definition to enhance installation (commissioning), operation, maintenance, and repair. However, product design remains a critical component of a successful strategy since it provides the baseline of the digital thread necessary to support successful digital transformation.

The digital transformation being implemented to support Navy logistics requires that a digital thread of information about the ships being supported and a digital twin of each ship be available and updated in near real time. One major departure for the Navy is that this digital thread and twin, to maximize their usefulness across the spectrum of logistics and support activities, needs to be based on 3D models and other data. That is, the full ship definition is a necessary component that will enable MBPS to be successful. In the past, most of this data was available only as 2D drawings, which are less informative and more difficult to maintain throughout each ship’s lifecycle.

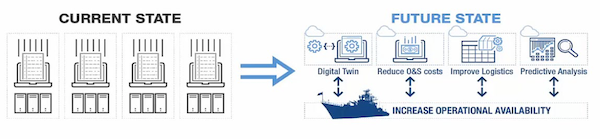

The new digital data definitions will also facilitate and allow much more flexible and valuable collaboration with domains and organizations outside of design engineering, further expanding the use and effectiveness of logistics information. To support this model-based collaboration, the Navy needs a set of capabilities built on a technology platform which will enable all of the data sources (various PLM, CAD, analysis, database, and other data sources) to work together as a single environment—essentially removing the current stove-piped silos that exist today. See Figure 2 which illustrates this point. The current situation is based on decades-old technology and processes; highly diverse, distributed, and disconnected data sources; inconsistent and incompatible data formats; lack of up-to-date ship configurations; and poorly controlled and secured data environments and processes.

Figure 2—Naval Logistics Stove-Piped Legacy Moving to a Modern Digital Platform

(Image courtesy of NAVSEA)

What is proposed and being implemented is a future state that will be a secure consistent environment that is much more sustainable and upgradeable, can be leveraged by more participants (including shipboard personnel), and will have much higher operational availability—overall significantly improving fleet readiness. The solution is not only being built on a new software architecture, but is also being deployed in a secure cloud environment (DoD FedRAMP+ IL5) which will enable the Navy to keep pace with evolving and new technologies and deliver secure services over a broad scope of people, organization, geographies, and processes. The cloud implementation should also greatly simplify deployment, education, training, maintenance, sustainment, and administration of MBPS.

Implementing PLM as SaaS on the secure DoD cloud provides a prime example for other DoD organizations that are pursuing digital transformation strategies. This type of environment provides operational and growth flexibility, lowers costs of entry and operation, and supports new ways of working that can streamline operations. For example, Covid-19 has many people working from home who thought they would never work remotely. This has introduced added challenges and urgency to support secure, alternative, easily-accessible working environments which are provided by SaaS in ways that on-premises, computer-based solutions cannot deliver. This also applies to providing access to shipboard and other remote personnel, e.g., contractors and partners.

The MBPS platform will be based on PTC’s modern, cloud-enabled PLM platform, Windchill. CIMdata defines PLM as “A strategic business approach that applies a consistent set of business solutions in support of the collaborative creation, management, dissemination, and use of product definition information across the extended enterprise, and spanning from product concept to end of life—integrating people, processes, business systems, and information.” The issue is not just about data but how data is used to support all types of processes, including logistics.

PTC Windchill is a web-based, scalable PLM platform designed to support product lifecycles, global collaboration, and innovation. It provides a secure environment for PLM that enables enterprises to integrate business processes and product data with dispersed divisions, partners, and customers. It is built on a 100% Web-based architecture for scalability and cost-effective support while providing strong security protocols to ensure IP protection.

Windchill’s cloud-based SaaS delivery supports rapid startup and deployment. Users and functional capabilities can be added on demand. The system is kept up to date by PTC managed services. Windchill is fully tailorable and cloud delivery makes it scalable for any implementation size.

Windchill incorporates full PLM capabilities for managing configurations, workflows, data and access control, and enabling implementation of a lifecycle digital thread (essential for enabling business digital transformation). Windchill functional capabilities include (but are not limited to):

- Product data management (PDM)

- BOM management and transformation including multiple BOM reconciliation

- Product variability management

- Change and configuration management

- Process workflow management

Windchill is designed to enable local and extended enterprise collaboration, which is important to the support of MBPS. Much of the collaboration within NAVSEA today requires manual effort, frequently using telephone calls and emails that are not traceable, and includes ad-hoc notifications that do not provide context. Windchill is designed to provide efficient, managed extended enterprise collaboration that is authorized and traceable.

Security is paramount in any DoD solution and implementation, and Windchill incorporates strong security protocols and standards. In support of DoD requirements, PTC is the only PLM software vendor to date that provides secure cloud-based PLM, Service Lifecycle Management (SLM), and Internet of Things (IoT) capabilities to the U.S. government.

Any major evolution or change in how information is created and used and how people access and work with that information can cause significant cultural change in addition to normal implementation and adoption of new technologies. New solutions must be deployed, either locally or via the cloud—in many cases with a hybrid combination of the two. Implementation of MPBS will impact multiple organizations, within and outside of the Navy. Careful planning and implementation will be required to achieve success.

MPBS will introduce new work and information flow processes across Navy logistics and their partners and suppliers. In many cases, these new processes will be significantly different from those currently in place. This is required to (1) take advantage of the new technologies and types of data that will be used, and (2) re-engineer the historical processes that have evolved over the last decades and no longer meet the Navy’s needs with new, more streamlined and sustainable processes.

Users will be required to change the processes they follow and the tools they use. In the naval logistics case, the user community will be quite broad including personnel in NAVSEA, sailors deployed on ships at sea, numerous contractors including shipyards and repair facilities, and equipment and materials suppliers. They will all need to be educated about the new environment and how it will impact their work and their organizations. This will require a carefully designed and executed cultural change management plan. A major change in how a person works (as will happen with MPBS) normally causes resistance and concern in the user community. Fortunately for the MBPS user community, the Navy and its partners use ThingWorx Navigate to create role-based user experiences specific to the job function and personas of NAVSEA support and engineering personnel. This will greatly accelerate adoption of the new solution. Additionally, a cultural change management program will educate users as to the need for and impacts of the new environment and processes being implemented. The Navy recognizes this critical issue and plans to undertake necessary actions to implement cultural change.

Additionally, the users will need to be trained to use the new tools, solutions, information formats, and processes being implemented. However, it is important that they be trained at the right time—when the solution they will be using is in place and the data they will use has been cleaned and migrated into that solution.

Finally, full data cleansing and migration will be a key to success. Accurate, complete data must be transformed and loaded into the new solutions. Failure to do so will impact adoption and trust by the users. Without that trust, users will not follow the new processes that will be put into place during the implementation. CIMdata experience shows data discovery and migration to be the most underestimated part of digital transformations.

The Navy currently has an outdated and cumbersome logistics situation with regards to supporting its fleet of ships. This negatively impacts operational readiness and capability. A modernization program will help resolve many problems and provide improved mission readiness while reducing cost and resources needed to perform the required logistical support.

MBPS is a large, ambitious program that will be a major step in achieving the Navy’s digital transformation strategy. It will replace historical, obsolete, but critical systems that support naval logistics with a modern, commercial solution that will be more sustainable and more easily kept up to date than the current combined environment. MBPS should also provide a more stable, reliable and accessible source of information to support Navy logistics into the foreseeable future.

The use of PTC’s COTS, secure cloud-based solution suite provides a strong basis upon which to build the new, modernized MBPS capabilities that will support naval logistics and be the basis for a digital platform that may be expanded to other areas.

Based on CIMdata’s experience, the Navy logistics program and its secure cloud-based SaaS model should be considered as a model for other DoD organizations planning to undertake a digital transformation.

Digital Thread—a communication framework that connects data flows which can be used to produce an integrated, holistic view of an asset’s data from physical and virtual systems (i.e., its digital twin) throughout its lifecycle across traditionally siloed functional perspectives.

Digital Twin—a physics-based description of a system resulting from the generation, management, and application of data, models, and information from authoritative sources across the system’s lifecycle. The Digital Twin must be more than just a descriptive model or collection of related digital information (e.g., a SysML)

1 Research for this commentary was partially supported by PTC.