Key takeaways:

- Digital threads enable sharing stable configurations of product artifacts throughout the product’s lifecycle.

- Without a comprehensive digital thread it is very difficult to manage the complex web of collaborative interactions that happen during engineering processes such as requirements traceability and change control.

- Digital threads support end-to-end traceability (from requirements through verification) within today’s prevalent heterogeneous tool ecosystems.

- Managing requirements (allocating, refining, and committing them) as part of a digital thread throughout the product lifecycle improves and accelerates decision making.

- SBE Vision provides solutions for developing, aggregating, and managing product artifacts, starting with requirements, and supporting decision making through digital threads.

Successful companies capture and refine the sequence of product decisions needed to make great, profitable products. The sequence, embodied in the digital thread, in which decisions are made during product development, deployment, and operation, is critical to determining a company’s long-term success. It embodies factors like safety margins, compliance, performance, and finances that influence when and how decisions are made. A safety margin example is crash worthiness of automobiles, aircraft, and other products. Decisions for the structure first and foremost focus on protecting the occupants. Performance for certain segments drives sales—whether it is range, acceleration, passenger capacity, or fuel consumption. In this case a lighter car or aircraft can go further, faster. But it also may need expensive materials to maintain structural integrity and protect the occupants. The correct balance between these examples is what drives success. The balance is achieved with a progression of decisions that are heavily influenced by the interactions of requirements linked to the components of the item—the digital thread contains and maintains critical relationships.[1]

Supporting complex decisions during product development and deployment is a systems problem. Systems are best designed around a framework of requirements for a multitude of capabilities, performance, safety, cost, and many others. The problem is to assure that the requirements are fulfilled and not violated throughout the life of a product. Exacerbating this are that requirements can and do change—which is fine as long as changes are controlled, fit for purpose, then managed through the lifecycle. It is one thing to define requirements before a product is designed and built, but after a product enters service new complications arise. An important issue is how the system’s defining constraints are maintained, adhered to, and managed as the product is placed in use, and inevitably changes. This requires the concept of a digital thread of the requirements and other product attributes tied to an ever changing digital twin. Digital threads don’t simply exist, they need a managed environment that understands a product’s requirements and how those requirements form the basis of the digital product definition and how it transforms over time. SBE Vision is providing a workable solution to the difficult problem of getting from product requirements and other data elements to a sustainable digital thread.

Systems Engineering and Digital Definitions

Systems Engineering as a discipline has existed for decades. Computer-based or digital systems engineering improves product robustness because it allows designers to see more interactions among requirements and solutions before a product is produced. However, there is confusion in what various terms mean. The sidebar contains a few key definitions that are used in this paper.

Requirements Use in Decision Making

A monolithic PLM system, which expects a single database of product artifacts for decision making, is neither workable nor practical culturally. Rather a framework of openness and services, coming from many innovative sources, leads us to a different architecture for PLM-enabling tools and services—a PLM platform. Within that platform, services for grouping related sets of objects to make the best decisions is required.

While the effort required for creating requirements, sharing them among tools, allocating them appropriately, and maintaining their initial traceability has been reduced, the substantial workload required to maintain these discourages many from continuing this activity throughout a product’s lifecycle, an essential factor for maintaining the digital thread. This undesirable workload when using requirements is typical of computer-based technologies wherein the original focus is on product artifact creation. Search and simulation have improved the use and reuse of these artifacts but still require special expertise and effort to perform completely and properly. Yet, as system complexity and the number of artifacts increases, poor requirements management, especially supporting traceability throughout the lifecycle, becomes a company’s Achilles heel.

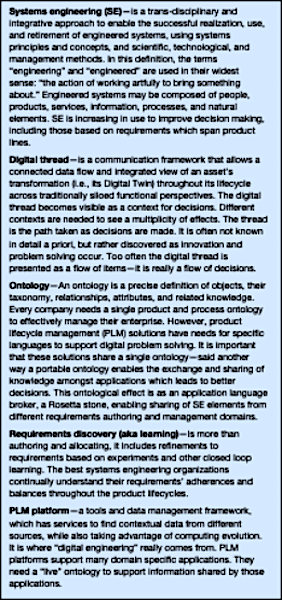

What is needed is in-context viewing and exploring to improve decision making. With a live, active, and connected ontology and best in class applications, sharing a context of requirements linked to product elements (parts, components, assemblies, etc.) creating stable configurations is critical. A configuration is the mechanism which provides a known correlatable basis for decisions, even when spanning multiple domains and applications. The DoD has described this as the “Authoritative Source of the Truth” as illustrated in Figure 1. This enables more participants, working in their native systems, to provide analysis and applied knowledge as decisions are made. Engineering becomes more simultaneous and the ability to shorten product development time while lowering costs is achieved. This maintains a company’s technological advantage.[2]

Figure 1—Sources of Data and Insights that Drive the “Authoritative Source of the Truth” (Courtesy of US DoD)

In the past few decades, monolithic PLM ecosystems have evolved in parallel with computing power. However, a problem arises because specific actors within the development and operational processes have codified knowledge and competitive practices inside their specific applications. Removing these capabilities implies a certain loss of knowledge so it becomes imperative to be able to work with those applications in a heterogeneous environment supported by a platform architecture.

PLM platforms delivered as Software-as-a-Service (SaaS) or Container-as-a-service CaaS have emerged providing a more innovative ecosystem. CIMdata research in the past few years has noted the growth of PLM platforms vs. monolithic solutions. This is the Innovator’s Dilemma for PLM ecosystems. But a platform with applications exchanging information is just a start. You also need consistent, repeatable contexts in a stable configuration across these applications.

A product ontology and services help create and explore solutions to discover and satisfy requirements, making sure stable configurations are used to exchange knowledge and insights consistently. This enables product system engineers to manage the complex systems emerging from their legacy environments. The result is that effective product decisions occur faster and change management cycle times and quality improve.

The Promise of Digital Engineering

Systems Engineering has improved with the power of computing, whether it is exploring solutions or safety margins of candidate designs. Computing speeds and simulation accuracies continue to advance. But with distributed computing came distributed data which can be difficult to manage. System engineers need stable, readily accessible configurations as baselines to help manage their decisions. File sharing alone is inadequate, especially when teams work together simultaneously. Given the proliferation of specialty systems used in today’s enterprises, PLM data managers also are challenged to link and manage disparate information.

Other engineering and manufacturing disciplines have a similar challenge. Bill of material (BOM) systems from logistics and manufacturing provide known configurations, but too often these are manually maintained. While computers help keep the records, it is still people who manually create BOMs.

Systems engineers often use new types of computing from advanced simulations to the latest advances in machine learning algorithms. Systems engineering is now being challenged with complexities due to increasing features, especially those in embedded software. The same level of automation done for chip design and manufacturing is now needed for all types of electro-mechanical systems. Instead of the BOM or configuration being driven by manufacturing processes today, it is more often driven by accelerating product innovations and changes. As decisions are made, the product/feature configuration must be known, reproduceable, tractable, and explorable all the time.

SBE Vision’s Solution

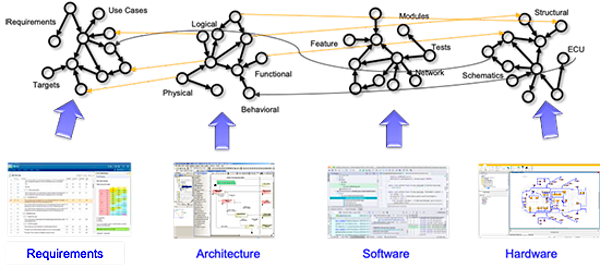

The Internet shares information efficiently via living links (called URLs). This provides a clue on how to proceed. Standards like OSLC and RESTful APIs provide some of the exchange capabilities needed to connect heterogeneous applications. This is critical because it is desirable to use the best requirements management applications with the best of an organization’s mechanical, electrical, software, simulation, and verification engineering applications, regardless of differences in structure and format of the data. To provide a stable context, i.e., a configuration, these applications need a service which can broker communications and data flows among them—similar to how the Internet works.

Systems engineers are the human focal point among the engineering disciplines—and with other business functions outside of engineering as well. They need digital engineering services to reveal and explore all requirements’ contexts so that customers and executives can make the best decisions for the product.

While remote linking standards like OSLC show promise, focusing on users’ views into sets of data also reveals inherent weaknesses: missing contexts, absence of cross-system search, and a lack of consistent user experience. As a result OSLC standards are best employed in specific situations where the links are few in number and the endpoints are not subject to frequent change. A focus on using requirements and designs in different contexts is a key to improving decisions, and, of course, systems engineers would be the guardian of these views, but they need to be delivered to the ecosystem of consumers in the context of their applications, not some SE specific tool. To accomplish this requires the bi-directional transformation of complex engineering data which effectively can only be achieved via semantic transformation.

Product development systems complexities are growing faster than predicted. Only small startup companies may have a monolithic digital engineering applications environment. The more common reality is that the need to use best of breed tools is essential to remain competitive. In this situation large disparate collections of data are available to exchange but putting it in a known context remains a challenge.

SBE Vision is developing solutions to support requirements, model, and verification management in a heterogenous authoring and usage environment, starting with DOORS Next and Teamcenter, and a variety of MBSE and analysis tools such as Cameo and Simulink. Their solution is based on open ontologies where users of any engineering tool can work in their preferred system and can examine requirements or models authored and managed in foreign systems.

As SBE Vision develops a platform technology to help build and maintain requirements traceability across requirements and model management tools, they realized the ability to establish and share a stable view—the configuration or context, was lacking. They addressed this weakness by providing contexts that can be coherently examined, even when they come from different requirements authoring systems. This capability allows systems engineers to provide views across stable digital thread contexts, thus improving decisions. These stable configurations can link any elements of information in a PLM ecosystem, not just requirements.

SBE Vision realizes that customers may have proprietary tools for engineering. to support company-specific or highly innovative product development. To support these situations, SBE offers a connector Software Development Kit (SDK) that allows companies to quickly create their own integrations to the digital thread. Its open architecture has been used to demonstrate five different engineering tools working together in an effective manner.

Mr. Chris Finlay, SAIC Digital Engineering Lead, has researched the importance of, and challenge of creating simple application user interfaces and the need for a way to integrate different applications using ontologies. “SAIC uses the SBE Vision Semantic Data Broker, because it aligns with our vision to connect DE tools semantically via the ontologies, eliminating tool import/export or remapping, and significantly increasing the efficiency of our DE deployments. It also provides a stepping stone to our planned future DE innovations, which would not otherwise be possible.” stated Chris to CIMdata. A few Automotive OEMs CIMdata spoke with are also exploring SBE Vision’s technology, wanting to solve the same integration challenge across a PLM ecosystem with heterogeneous applications. This is an important advance to anyone’s digital engineering strategy. CIMdata believes this kind of innovation for SaaS is essential for achieving the Authoritative Source of the Truth—the digital thread—on demand, at any point in a product’s lifecycle.

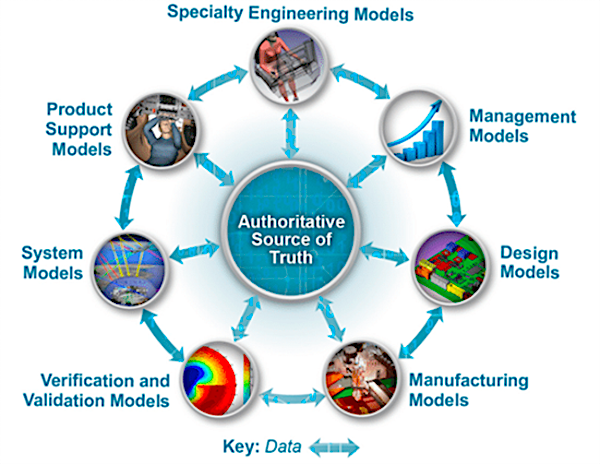

Figure 2, is an example of how SBE Vision can support the Semantic Data Broker by linking multiple disparate models without regard to traditional application boundaries. In this illustration traceability is accomplished via a combination of OSLC and Digital Thread subscriptions:

- IBM DOORS Next holds industry requirements interlinked with mission requirements. Both of those requirements sets are satisfied by use cases and activity behavioral models in No Magic’s Cameo MBSE modelling tool.

- There is also a logical system architecture in Cameo which satisfies the requirements from DOORS Next.

- There is a physical architecture model in the IBM Rhapsody MBSE tool which realizes the logical architecture in Cameo.

- The Cameo and Rhapsody architectures can be analyzed within Mathworks MATLAB/Simulink which is also connected to requirements and test plans.

- There are design artifacts, authored in ECAD and MCAD tools, managed in PLM systems, which realize the physical architecture from Rhapsody and are also linked to Simulink and Verification models.

- The requirements, use cases, and architectures form the framework of the verification and test plans of the design artifacts, which is done in a verification planning tool.

SBE Vision ties all of these various forms of the system’s data together and allows that data to be shared among the disparate tools.

Figure 2—SBE Vision as the Basis for a Semantic Data Broker (Courtesy of SBE Vision)

Summary

SBE Vision and their partners have applied ingenuity and the benefit of Moore’s Law to solve a problem inherent in product development systems data exchanges. The configuration is what establishes the context that lets us determine the authoritative truth and embody it in a digital thread. This truth is temporal: as new knowledge is learned the contexts must adjust. Manual methods of requirements and BOM management must become semi-automatic allowing the revelation of knowledge to the systems engineer to explore insights and adjust requirements—engineer them! Digital Engineering Strategies need solutions like the SBE Vision SDK to help build and maintain digital threads, providing long term benefits, even when they have heterogeneous application environments.

Early adopters have started using this technology and are gaining momentum, and CIMdata expects more to do so. The fastest product innovations occur in a diverse PLM ecosystem, which also fosters process and application innovations—a proven and needed ability to maintain technological advantage. SBE Vision is worth your time, evaluate their solution, they are riding the next wave of engineering, engineering systems based on requirements use and product risk reduction across the whole lifecycle.

[1] Research for this commentary was partially supported by SBE Vision.

[2] DoD Digital Engineering Strategy, June 2018