Key takeaways:

- Printed Circuit Board (PCB) manufacturing and assembly efficiencies are coming to the fore front, driving demand for first time producible electronics.

- More sensors and their electronics on smaller PCBs now enable massive data collection for performance analytics.

- PCB Verification and Validation will benefit with more manufacturing IoT operational data collection and advanced analytics leveraging AI/ML.

- PollEx’s Unified User Interface and well-integrated analyses accelerate the electronics design and verification process including manufacturing requirements.

Altair’s expanding electronic system modeling improves electronic and mechatronic system robustness for multiple disciplines: structural, thermal, EMI/EMC, optimization, and controls.

Products in all industries are becoming more and more dependent on electronics and software functionality including being connected as “smart” Internet of Things (IoT) devices. The design and development of complex cyber-physical systems requires well integrated capabilities for cross-disciplinary mechatronics simulation, analysis, and design optimization supported by advanced data analytics.[1]

Altair understands that efficiently designing products requires a focus on manufacturing and robust system designs done with state-of-the-art computer-aided engineering tools. Altair is one of the mechanical systems CAE leaders (e.g., planes, trains, and cars) focusing on product durability and mass production efficiency. Altair’s capability to integrate with many MCAD authoring tools lets them focus on multi-physics simulation technologies leveraging efficient HPC utilization for large scale models. Note the different views of layout/mockup, signal clarity, and thermal or vibration heat map in Figure 1.

Figure 1—Engineering Across the Electrical and Electronic Disciplines Need Multi-Physics Models

Altair realized the next step is applying their proven CAE techniques to electronics and with interfaces to mechatronics. Altair acquired a Printed Circuit Board (PCB) Electronic Design Automation (EDA) design suite in 2019 from Polliwog of Korea with this goal in mind. This product suite is now branded as PollEx.

Altair’s Vision for Integrated Analyses

Simulation driven design has been used extensively in automotive and aircraft design using Altair’s solutions. Altair’s leadership combining simulation expertise with machine learning and artificial intelligence has been reported on in late 2019.[2] Now Altair has acquired and improved Electronic System Design simulation solutions to achieve similar benefits for products having increasing electronic content, typically installed on a PCB. There are benefits when the physics coupling between vibration, heat, and magnetic interferences are discovered, understood, and resolved together across all physical disciplines. Altair’s PCB CAE capabilities provide improved performance understanding while gaining insights from all datum, both predictive (simulation) and measured (laboratory and field use)—this is a more wholistic and integrated approach.

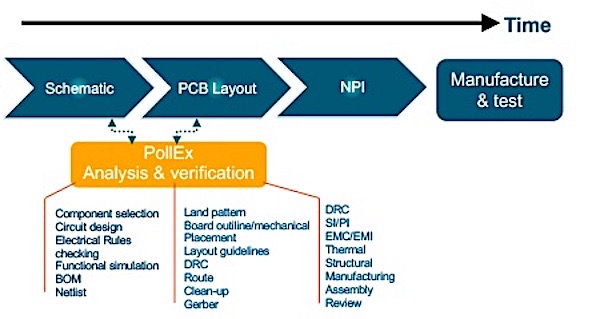

Simulation Driven Design tools should also comprehend manufacturing and assembly practices—which are often a company’s competitive advantage. Figure 2 shows the elimination of manual review steps in a typical PCB design process thanks to an ability to examine different views—often as simulation-based heat maps, when circuit or PCB layout engineers want to confirm a decision. Notice manufacturing engineering practices and guidelines are available to engineers as they start a design. As new product introduction (NPI) occurs, launching the PCB assembly line goes much quicker. Gone are the wasted hours developing a circuit or board which cannot be profitably produced in volume.

Figure 2—Simulation Driven Design Shortens Time to Market While Improving Reliability, Reducing Costs, and Managing Risks

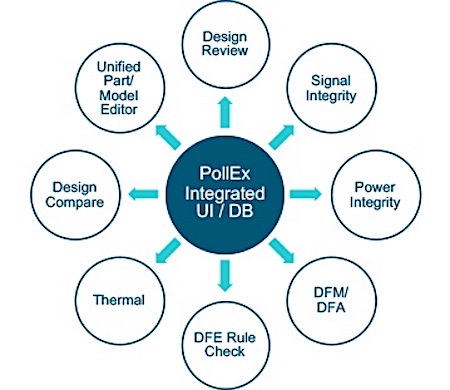

Within the electronic design disciplines, Altair’s PollEx Unified User Interface encourages collaboration when examining performance from different points of view—signal integrity, board hot spots, layout for manufacturing efficiency, and more. Figure 3 shows the activities which are moving to the left, earlier in development process with analysis leading the design. A consistent user experience encourages discipline specialists to interact virtually and improve electronic designs before prototype samples are manufactured. PollEx provides this Unified User Experience for PCB design review, verification, analysis, and manufacturing. The PollEx Unified User Interface is integrated with the EDA database that contains design, simulation, manufacturing planning, and various rules based on technologies and past mass production experiences (DFM/DFA). Samsung SDI has used the PollEx suite for designs of their consumer products which contain densely packed PCBs, annually saving US$6 Million.[3]

Figure 3—PollEx Integrated User Interface and Database

A 2019 CIMdata commentary summarized Altair’s view and evolution of the AI Promise when Physical Data Collection and Models are continuously combined.[4] CIMdata expects the same benefits will be seen as PollEx becomes more integrated into the Altair family of solutions. Altair’s clear definition of Digital Twin—a math-based representation of a product throughout its life will improve electronics reliability, manufacturability, and service/upgrades.

In the age of IoT and Industry 4.0 where data is collected continuously from products in service, the digital twin simulation models can continuously be refined to accurately predict the ongoing performance of a product. With PollEx, Altair now has a bigger footprint in the design and manufacture of PCBs needed for IoT sensing and Edge computing.[5]

Altair’s Electronic System Design Solution Suite

In fact, Altair ESD covers more than just PCB design and manufacturing. Figure 4 shows the breadth of their solutions including electrical signals in the air (i.e. radios), mechanical enclosures, heat transfer, actuators/sensors/PCB and embedded software, circuit design, and electronic manufacturing planning. All these take advantage of Altair’s efficient HPC management when executing simulations as well as cloud-based machine learning from assorted field data. Improvements in manufacturing are realized as analytics bring insights from all those IoT measurements.[6]

Figure 4—Altair Solution for Electronic System Design—All Disciplines

Conclusion

Altair understands and fosters the importance of systems simulation driven design and manufacturing. Altair has always had a system of systems mindset which now includes electronics, electrical, radio coverage, and beyond. Altair is building on their successful journey with mechanical and mass production models (multi-physics, layout/flow). Altair’s CAE track record with their focus on data collection will continue to improve their position to maintain models throughout a product’s life.

Sensor miniaturization sets the stage for even more measurements accelerating data collection leading to improving AI/ML applied to product evolution—something Altair has focused on in recent years for mechanical engineering. Key in this development is the ability to share insights and views across disciplines. Decisions made together from different views makes models more meaningful and more timely. These are the models which enable timely, earlier decisions. Such models can be used after a product is in the field to consider field upgrades—potentially leading to new revenue streams.

CIMdata expects to see more from Altair as the simulation and data analytics capabilities expand to include decision making across the entire product lifecycle, both earlier and later. Altair’s, combining Electronic System Design solution with their proven multi-physics simulation solutions, being continuously improved by AI/ML, has now positioned itself with tools and techniques to model, simulate, and analyze products and their connection with smart IoT devices and services—be they robots, cars, or home appliances and gadgets.

[1] Research for this commentary was partially supported by Altair.

[2] https://www.cimdata.com/en/resources/complimentary-reports-research/commentaries/item/12998-altair-continues-to-expand-solution-portfolio-for-simulation-and-analysis-of-mechatronics-systems-commentary

[3] See Altair, Improving PCB Development: https://www.altair.com/customer-story/samsung-improving-pcb-development

[4] https://www.cimdata.com/en/resources/complimentary-reports-research/commentaries/item/12998-altair-continues-to-expand-solution-portfolio-for-simulation-and-analysis-of-mechatronics-systems-commentary

[5] https://en.wikipedia.org/wiki/Edge_computing

[6] See Altair, Manufacturing Analytics: https://www.altair.com/manufacturing-analytics