Key takeaways:

- New advanced technologies and products with embedded software have created new kinds of disruptions and opportunities that require companies to rethink how to design and deliver their offerings. Increasingly, customers are demanding complete solutions—smart, connected products and anything-as-a-service offerings.

- Companies looking to capitalize on these trends, including social media, mobile technology, advanced analytics, cloud computing, the Internet of Things (IoT), and Industry 4.0, will require a unified platform to support their product lifecycles that span from idea through life, and that will leverage information from any source, at any stage in the lifecycle, to power continuous product and service innovation.

- Traditional, on-premises design-focused systems weren't designed to manage launching and scaling of global products and services. With their focus primarily on the design phase, crucial supply chain information remains locked or scattered in siloed systems which support the supply chain and ERP processes and this adds to supply chain risk, potentially a slower time to market response and/or poorer product quality.

- Oracle Cloud PLM, a solution integrated with Oracle's broader Supply Chain & Manufacturing (SCM) applications, provides a comprehensive platform to standardize and structure a continuous, end-to-end innovation process by delivering consistent real-time and connected data to cross-organization stakeholders to expedite data-driven decisions, proactively identify and mitigate risks, and respond to market shifts with relevant innovations.

- Oracle Cloud PLM delivers continuous innovations by rolling out new features, functions, and best practices on a quarterly basis. Customers can leverage these capabilities as they see fit to address their business challenges by activating application capabilities as they need them.

Introduction

Global value chains get more complex seemingly every day, and have to support an increasing pace of innovation just to keep up with the market, let alone to get ahead of the game. Products in almost all industrial segments have to respond to global trends that impact business and society at large, such as social networks, the ubiquity of mobile technology, cloud, the IoT/IIoT, Industry 4.0, and smart, connected products. Manufacturing companies seeking to excel in this complex environment need to innovate to survive and product lifecycle management (PLM) is the nexus for managing the lifecycle from idea through life. Oracle is a global enterprise software leader, and their supply chain management strategy and offerings span the lifecycle far beyond those of most PLM solution providers. This commentary focuses on their vision for continuous innovation and how it might address critical needs for industrial companies facing our increasingly smart, connected future.[1]

Connecting Global Value Chains Across the Product Lifecycle

Static supply chains are a thing of the past. Successful companies rely on dynamic value chains, where their differentiation can rely on the partners they can leverage. These value chains are often global, both to better serve the home market and, increasingly, to meet the specific needs of local markets targeted for growth. CIMdata has been involved in the application of digital technology to the product lifecycle for almost 40 years, and the pace of innovation always seems to be accelerating. Today, the technology within products changes so fast that one almost has to rely on partners and acquisition strategies to leverage new technologies quickly enough.

Over the last fifteen years, several megatrends have dominated the information technology (IT) landscape and, one could argue, global society at large. Social computing platforms have come to dominate human discourse, often used on ubiquitous mobile devices. Cloud technology has changed the economics of IT and for many it is no longer “why cloud?” but “why not cloud, and when?” The Internet of Things and its cousin the Industrial IoT are key to our smart, connected future where virtually everything in the physical (products, assets, buildings, infrastructure, etc.) and natural world is connected, including us. These trends all contribute to the massive explosion of data available to mine for insights and operational improvements using both traditional analytics and artificial intelligence/machine learning (AI/ML) approaches.

These megatrends affect just about all industries and creates significant new opportunities for innovation. A lot of product value of smart, connected products is delivered in electronics and software, often as part of subsystems from suppliers. The IoT/IIoT offers enhanced capabilities to learn from a product’s usage to inform the ideation process. Real data from real world use trumps data from warranty returns and customer complaints. It can help yield better products with higher customer satisfaction and is essential in regulated industries. For example, the Corrective Action Preventive Action (CAPA) process is mandated by the US Food & Drug Administration (FDA), and is pivotal to support good manufacturing and quality management practices. CAPA requires tracing issues in the field backwards through the lifecycle to determine the issue’s root cause and to prevent it from happening again. Being able to track and manage remote assets using the IoT leads many companies to value opportunities post-sale, such as add-on products or subscription services. Some want to make the move to a full product-as-a-service model, selling not a refrigeration system but a commitment to keeping a volume of products in a desired temperature range over a specific period of time in a specific location, often termed a service level agreement (SLA). Promising performance is complicated but the IoT and analytics help make product-as-a-service feasible and, potentially, profitable.

Companies looking to take advantage of these opportunities need information technology and processes that span the product lifecycle, and that can help satisfy customer needs by leveraging the best your value chain partners have to offer. CIMdata’s Enterprise Application Architecture (EAA) model, showing in Figure 1, highlights those key linkages and articulates a set of information capabilities necessary to address customer needs.

At the core of Figure 1 is the product lifecycle, from ideation through to installation, service, and recovery. While many solution providers talk about “selling PLM,” CIMdata does not see PLM as a product or technology that you buy. We consider PLM to be a strategic business approach enabled by a consistent set of business solutions that support the collaborative creation, use, management, and dissemination of product-related intellectual assets. These assets cover both the virtual product and the virtual processes for its manufacture, installation, and maintenance. Over the last ten years, solutions in the PLM market have evolved for delivery as an innovation platform that supports the extended enterprise from idea through life. These platforms connect value chain participants, supporting collaboration around lifecycle data using consistent, repeatable processes. These platforms often include more capabilities from Figure 1 beyond what many would include in PLM, including modern ways of integrating with a wide range of other enterprise software.

Figure 1—CIMdata's Enterprise Application Architecture Model

Since PLM emerged, CIMdata has spoken about the need to capture and structure information from idea through life to be able to interrogate the development cycle to understand decisions and access information from various product-related activities. CIMdata referred to this information store as the “bill of information,” very similar to the phrase in vogue today “the digital thread.” CIMdata defines the digital thread as the communication framework that allows a connected data flow and integrated view of an asset’s data (i.e., its digital twin) throughout its lifecycle across traditionally siloed functional perspectives.

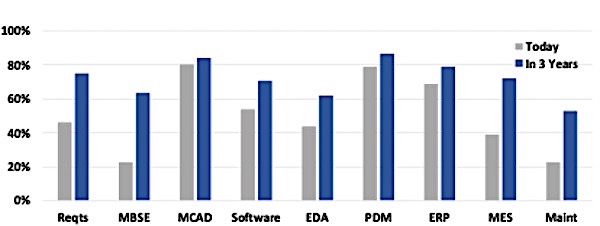

Information for the digital thread can come from a wide range of sources. In a recent survey, CIMdata asked industrial respondents what types of applications or processes were currently part of their digital thread and what might be linked in three years. As shown in Figure 2, our questions focused on a path from idea (requirements) through design (from sources like model-based systems engineering, mechanical CAD, software development, and electronic design automation), manufacturing (enterprise resource planning and manufacturing execution systems), and field service. Not surprisingly, many include MCAD, product data management (PDM), and ERP as this is the classic engineering bill of material (EBOM) to manufacturing BOM (MBOM) handoff. But requirements are important to over 40% today and all categories are projected to grow significantly in three years. In a subsequent question we asked them what other things they plan to connect and we got dozens of answers, including customer relationship management (CRM), human capital management (HCM), and quality management systems (QMS), among many others. Companies will need to choose and fully implement a platform that can handle these disparate sources and best leverage them.

Oracle is a global enterprise software leader that is focused on delivering their considerable portfolio on the Oracle Cloud and plan to bring it to bear to enable “continuous innovation” in their industrial customers. The next section describes their vision and how their solutions can help their clients reach it.

Figure 2—Contributors to an Industrial Digital Thread Today and in Three Years

Oracle Cloud PLM: A Platform for Continuous Innovation

Oracle has offered product lifecycle management solutions for over twenty years, but they significantly expanded their commitment to the segment and renewed their PLM journey by acquiring Agile Software in 2007, one of many segment-leading companies Oracle acquired during that period. Since then, Oracle has rewritten their PLM, ERP, SCM, CX, and IoT applications on a new unified cloud platform that leverages a single product record and BOM to create a true digital thread that runs through the entire product lifecycle. Using this platform approach, siloed development and engineering processes can shift to become more integrated and cross-functional across the extended value chain from initial idea through planning, sourcing, manufacturing, and service.

This leads to the time worn argument in software: integrated or best of breed? Best of breed solutions can offer unique capabilities and that is why there is always an argument to leverage them. But integrated business suites do have value, particularly in an environment where disparate data sources must be tapped and leveraged to support products with embedded software and anything-as-a-service offerings.

Oracle’s Business Platform offers the best of both worlds—a homogenous solution that spans from idea through life and has readily available best-in-class heterogenous cloud applications. It's a single platform that allows customers to readily extend to new processes, new use cases, and new organizations without having to rewire an end-to-end solution. This offers a value proposition that other providers lack. Since it has applications in many segments, Oracle Cloud provides an advantage when developing integrations with tangential business processes. The underlying data models already “understand” the needed data and processes. This deep knowledge means that companies can better understand, augment, and extend the definition as maturity strengthens, thus better managing their digital thread.

Replacing legacy systems, spreadsheets, and fragmented data that can often create knowledge latency, companies have leveraged Oracle Cloud PLM to help align and standardize their data (through the enterprise product record and evolving BOM) to make innovation continuous and accelerate the new product development and introduction (NPDI) processes. The added value of Oracle PLM is that it’s single data model architecture can capture IoT data from fielded products and leverage built-in social listening and analytics capabilities to turn data from global value chains into actionable insights.

To help further position continuous innovation, Oracle is focusing on lifecycle-specific use cases and is delivering role- and industry-specific capabilities that can support their customers’ evolution into new business models like product-as-a-service. Oracle PLM’s strong master data management (MDM) solution is a key element of Oracle Cloud Applications and is tightly linked with their considerable data lake capabilities, increasingly required to manage the oceans of data being generated every second. This provides their customers with a comprehensive foundation to standardize and structure a continuous and end-to-end innovation process by having access to real-time, connected data for cross-organization stakeholders thereby helping them expedite decisions, proactively identify and mitigate risk, and respond to market shifts with a relevant innovation.

Conclusion

CIMdata has followed Oracle for decades. Their business platform offers a value proposition that many best of breed and legacy solution providers can't—a comprehensive enterprise product record that delivers the product foundation and digital thread required to support today's end-to-end innovation processes. Their broad-based PLM capabilities include more details about manufacturing and downstream applications than their main PLM competitors. This makes sense as Oracle has a broader corporate vision, one that spans the enterprise software domain as illustrated in CIMdata’s EAA model shown in Figure 1. Their approach is defined as part of Oracle’s broader SCM/value chain vision, which aligns well with the smart, connected future envisioned as part of Industry 4.0, a German-defined vision that is driving advanced manufacturing investment around the globe. Oracle is recognized as a leader in ERP and Supply Chain Management solutions by analyst firms that closely track these application segments and this strength powers their strategy.

Oracle's cloud-based business platform includes a comprehensive set of solutions that many discrete manufacturing companies have identified as necessary to support their innovation initiatives. With Oracle’s platform customers can leverage a single data model architecture which standardizes and structures a continuous, end-to-end innovation process offering real-time and connected data for cross-organization stakeholders. This approach helps companies make data-driven decisions faster, proactively identify and mitigate risks, and respond to market shifts with more relevant innovations.

As innovation becomes even more crucial across all aspects of a company’s business, Oracle’s role- and industry-based capabilities focus on enabling their customers to continuously innovate across their extended value chains. Oracle Cloud PLM rolls out new features, functions, and best practices on a quarterly basis. Their customers can leverage new technology and capabilities when they need them and as they see fit to address their business challenges. Their business platform includes solutions that many companies see as key contributors to the digital thread and can natively support nearly all of the capabilities shown in Figure 1. Oracle Cloud PLM is a solution that, when combined with data from IoT, built-in analytics, and AI/ML, can help capture and manage the as-maintained BOM, critical to profitable product-as-a-service strategies. CIMdata is impressed by the range of use cases supported by Oracle Cloud PLM.