Key takeaways:

- Onshape optimizes the development process by providing advanced, instant collaboration between designers, suppliers, and product stakeholders.

- Users gain remote access to Onshape through a browser with no hardware restrictions.

- Onshape offers the agility to explore alternative design solutions.

Recently the world experienced a dramatic upsurge of web-based communication. Teachers leverage cloud-based tools to instruct their students; office workers meet in web-based meetings to conduct their business. Already a factor in industrial collaboration, cloud-based interaction solidified as the preferred mechanism for engineer-to-engineer and OEM-to-supplier information exchange. Yet, most industrial collaboration solutions only support asynchronous collaboration—a contributor posts information and a colleague at a later time accesses that information and responds in kind. An asynchronous collaboration solution, while useful, lacks the spontaneity found when two contributors meet face-to-face in a synchronous design session and their product ideas feed off each other. CIMdata has previously researched innovation and has published that, “There is substantial opportunity in the business of innovation to achieve better results more efficiently.” CIMdata believes the level of innovation that can be achieved in product design is heightened when designers work together to share their ideas.

If unable to work in person, two geographically separated product designers or a company design engineer and a supplier, the leading-edge solution is to have both working on and seeing the same product model at the same time. PTC’s[1] Onshape CAD design solution provides just such an environment. Onshape was developed to run in the cloud and allow more than one designer to concurrently work on the same model and immediately see the interactions of each other. CIMdata sees Onshape’s ability to have multiple designers work on the same model as a leading factor in design collaboration.

Onshape

Onshape was founded in 2012 by CAD veterans Jon Hirschtick and John McEleney, both Solidworks CEOs. Mr. Hirschtick founded Solidworks when he recognized the technology wave of personal computers was gaining ground in the industry. Once Solidworks was acquired the two shifted their focus to the current technology wave of the cloud and Software as a Service (SaaS). The Onshape solution is a SaaS product that makes use of cloud computing with compute-intensive processing and rendering performed on secure AWS cloud servers. Users interact with the software via a web browser or the iOS and Android apps. This reduces the need for any IT (information technology) support and allows remote access to Onshape with no hardware constraints. CIMdata recognizes this as a strength in that Onshape users can work from anywhere, at any time, on any device. PTC acquired the company in 2019 when they too saw the technology wave of cloud-based software building momentum. CIMdata sees the acquisition as a strategic move for PTC to take advantage of the growth opportunities for CAD in the cloud.

Innovation and Collaboration

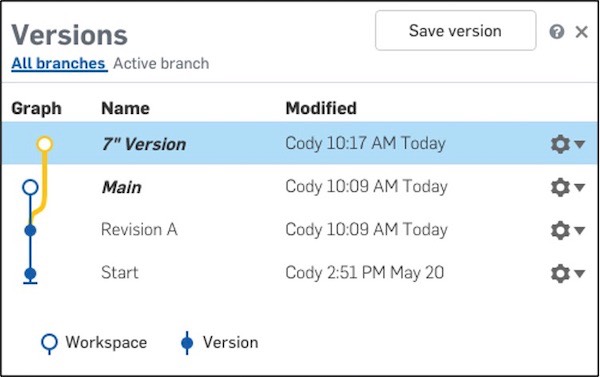

Arguably few truly innovative products are the brainchild of a single individual. More likely two or three design engineers working together in a robust give-and-take of ideas produce new product ideas. Onshape provides for this possibility. Not only does Onshape allow multiple individuals to collaborate concurrently on a single shared design with live chat and commenting, but the solution also supports the concept of branching and merging alternative design directions. The team can create a version of the model with experimental branches off a core design.

By generating a branch off the current version of the product model (Figure 1), the users can create a workspace independent of others working on the model. They can then experiment with their ideas making alterations to the design without impacting others. By seeing the changes one designer makes, they can build on it with their own proposals. At any time the team can return to an earlier stage of the model if needed or merge the best elements from their multiple alternative designs together. CIMdata realizes this synchronous design capability is a major win for users and design innovation.

Figure 1—An Example of Branching in Onshape (Courtesy of PTC)

Onshape offers similar benefits for companies working with suppliers. A manufacturing company can invite a supplier into the product model workspace and point out any subtle issues in the overall product assembly. The company designers and supplier representatives can discuss and pinpoint potential concerns they have for the supplier built component or subassembly. That level of communication helps accelerate the overall product development process.

Summary

The cloud has become the medium of information exchange around the word. The manufacturing industry is increasingly leveraging the cloud for their design environment and when working with their supply chain. Onshape’s positioning as a SaaS product running in the cloud is well positioned to satisfy those needs. CIMdata also believes that Onshape’s ability to have multiple designers work together and see each other’s progress can foster a level of innovation that will richly reward those companies that take advantage.