System of Systems Engineering Requires Architectural Frameworks

Key takeaways:

- New sensors, automotive software including on-vehicle embedded and off-vehicle (cloud) software, and computing advances are the building blocks that are enabling advanced driver-assisted system (ADAS) features and eventually driverless autonomous vehicles. The exponential growth of vehicle-related electronics and software is changing vehicle differentiation, development, verification and validation, and lifecycle support.

- To bridge the gap between today’s advanced driver-assisted systems and tomorrow’s fully autonomous vehicles (AV), transportation management systems, from fleet coordination to traffic management, need to become connected with today’s vehicles.

- System of systems practices are needed to organize multi-disciplinary information, pre-validate complex system assumptions before detailed designs, and include new groups outside of historical vehicle engineering and manufacturing.

- Coordination beyond a vehicle in a traffic ecosystem requires a blueprint for safety cooperation. An architectural framework for situational awareness, e.g., obstacle detection and avoidance, is needed so AVs can assist each other.

CIMdata’s definition of product lifecycle management (PLM) emphasizes the complete lifecycle of a product and all its related data, from requirements to actual performance, to planning and supply chain participation, then mass production, and product service and upgrades. Systems Engineering helps Autonomous Vehicle (AV) development and operations by considering a broader context—one that includes the operational environment of the vehicles. Model-based systems engineering (MBSE) helps support increasing product and systems complexity driven by more sensors, actuators, and computing electronics. Accurate digital twins have improved virtual and physical correlations delivering improved and faster solutions for AV development and validations.[1]

In a recent CIMdata eBook covering AV development, we described the need for a broader view of collaborative engineering and operations where the AV may well rely on feedback from the city and other AV sensing to provide safer, efficient route guidance, and robotic driving[2]. It summarized AV challenges:

“There remains a gap in the journey from today’s Level 1, 2, and 3 ADAS capabilities to capabilities needed for a fully AV…With AV development, integrating the sensing, communications network, and traffic management beyond the vehicle will be required to bridge this gap. Complexity grows as connecting vehicles to different infrastructures expands. Connected transportation systems with AVs go beyond the boundary of an individual vehicle. Complexity is caused when connecting vehicles to different infrastructures—starting with service and moving quickly toward travel efficiency. A system’s engineering view of these different systems’ boundary diagrams shows that the vehicle is now a sub-system of a connected transportation service.”

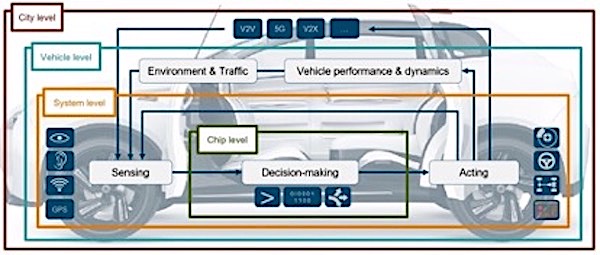

Figure 1 shows the systems of systems AV Product Development contexts, from chip to system to vehicle to city, which is driving Siemens AV solutions development.

Figure 1—System of Systems AV Product Development

(Courtesy of Siemens)

As product complexity increases with new and expanded features, even being delivered while a product is in-service, a more expansive use of broad, integrated MBSE is needed. Siemens Digital Industries Software (Siemens) continues to expand their Systems Engineering solution set, now addressing product development within a system of systems, relying on technology like the Arcadia method[3] and the emerging version 2 of SysML. Building trust within the operational environment requires an appreciation of system of systems thinking, starting with systems engineering practices applied to not just the AV during development, but also the environment in which it operates, especially as that environment changes.

Engineering Beyond Individual Vehicles

AV development requires considering complex operational scenarios which can only be done by applying model-based systems engineering principles supported by architectural frameworks to ensure consistency. By leveraging real-world measurements to correlate virtual model-based scenarios using digital twins, assessing complex operational anomalies will make AVs upgrades more reliable and thus earn customer and society trust.

At the 2021 Global INCOSE conference, Mr. Mark Malinoski, Siemens’ MBSE Solutions Director, presented more details on their vision of systems of systems development and the integration of it with continuous testing and incremental development. These are key capabilities for successful operational upgrades after the AV is manufactured. One can even imagine different AV feature sets based on the specific city they operate in, and then adapting as the AV moves from one city to another. Siemens sponsored projects have started and forums like INCOSE are now seeing the pilot results.

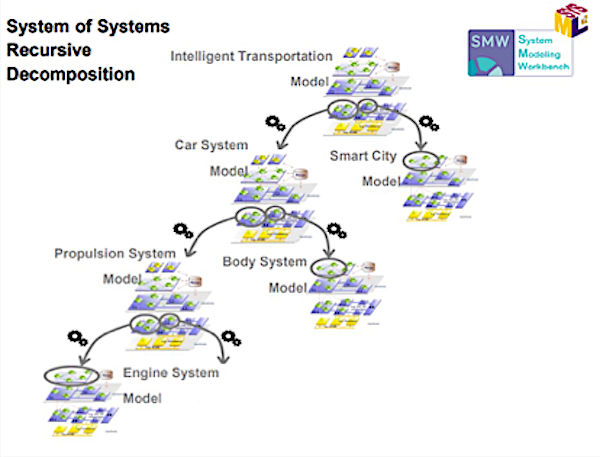

Figure 2—Autonomous Vehicle’s Architectural Framework

(Courtesy of Siemens)

To support this vision, an architectural framework is needed to exchange digital twins that must be available on demand and accurate to the latest customer usage patterns. Figure 2 describes capturing the breadth and integration needs for AVs operating in a city. They comprise the Intelligent Transportation System. Different cities will likely be at different levels of sensor fusion and traffic management. AV developers need to support these various kinds of cities. The gears in the figure identify the need for tools that enable joint systems engineering, across AVs, their subsystems, and the cities they will are used.

What Siemens is Demonstrating with Architectural Frameworks

For AVs, one must appreciate that the top-level requirements at the city and transportation system are evolving in parallel, maybe even behind the AV manufacturers original development. So, engineering an adaptable AV that is resilient in the future becomes essential. Competitive and complexity pressures require faster decisions made well.

Product requirements are best managed in a repository containing the authoritative truth that enables different views and analyses as product lines are conceived and enhanced. A bill of requirements (BoR) should be managed like a BoM, as part of the product’s Bill of Information (BoI). The BoI is inclusive of all information related to a product covering its whole lifecycle. The new challenge is requirements not yet known (e.g., the next city where the vehicle is used).

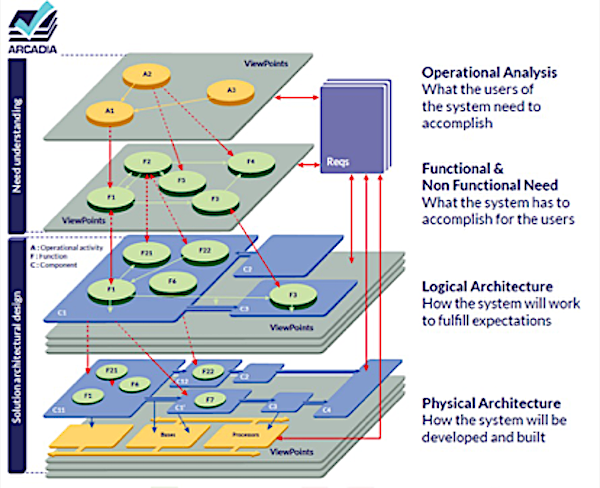

Siemens recognizes that all core business processes for all product domains must collaborate not only to produce an AV, but also to provide the appropriate service and upgrade it during use. This means breaking down diverse data silos, providing a capable and flexible work product repository assisting complexity management, data sharing, and configuration management. Siemens integrated MBSE solutions have been designed to help their clients bridge gaps between engineering disciplines, which in turn improves collaboration, and even spans organizations. Connecting SE with all requirements is shown in Figure 3.

Figure 3—Connecting SE with Requirements and Viewpoints (aka Contexts)

(Courtesy of Arcadia)

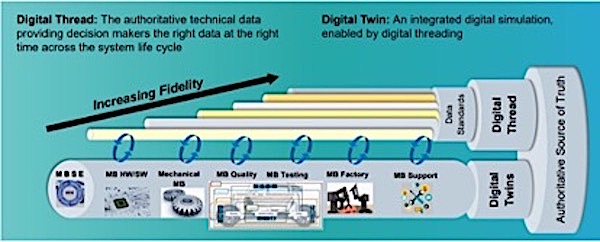

Figure 4 illustrates how digital twins and threads lead to the authoritative source of truth with the broader AV product development contexts depicted in Figure 1. These contexts establish the digital twins. AV development needs MBSE to cover these broader domains and their viewpoints (i.e., contexts) beyond a single vehicle. AV adaptation to its operational environment needs accurate digital twins of the systems they operate in (the city). Continuous upgrades and taking advantage of external sensing for traffic, obstacles, and even time of day will make for safer AVs. Digital threads and useful twins will help. Siemens’ approach utilizes Teamcenter to provide a product lifecycle collaboration backbone that orchestrates the appropriate MBSE models of everything.

Data integration across siloed applications, from separate organizations, is a key to success for streamlining broad systems engineering and keeping it “closed-loop” with continuous, contextual feedback. Using Siemens’ Mendix technology for open-systems integration with other systems, the Teamcenter platform expands as digital twins are used everywhere. Combined with the Arcadia method (see Figures 2 and 3), the systems of systems engineering needed for AVs development is possible now.

Figure 4—Digital Twinning and Threading Provides Truth

(Courtesy of Siemens)

The notion of the expanding Agile development’s DevOps[4] into interconnected infinity cycles helps shift the mental model to one that builds trust continuously across the lifecycle. A few automakers are asking for the SAFe[5] which expands agile practices into portfolio planning and program management as well as operational considerations, all while executing incremental product improvements and deployments. As new AV field and associated phenomena results are captured, models and their simulations will be improved, and quality risks and learnings can be explored. It incorporates lessons continuously through improvements learned effectively. With AVs, this will include the city where it operates, which is outside of the vehicle manufacturer’s control. Getting multiple AVs manufactured and serviced by different competitors to share their operational awareness in a framework to collaborate needs PLM and SE to work across organizations.

Concluding Remarks

Siemens’ AVD solution set broadens SE capabilities enabling a system of systems framework needed for AV development and operations. CIMdata forecasts that companies connecting data with learning digital twins will realize significant benefits during AV development and operations—building trust with cities and passengers. Siemens’ advances in Quality Management[6], Systems Engineering[7], Simulation with Executable Digital Twins[8], and many more concepts in the works will provide a rich set of capabilities that product designers will use for the next generation of mobility, Autonomous Vehicles. Siemens is addressing the gaps in AV capability with engineering tools that can be used to explore operational conditions as they are experienced. As usage experiences are collected, continuous testing can be updated with newer scenarios, which in turn build a basis for systems validation.

The AVD focus from Siemens expands SE beyond a specific AV. By providing examples of their tools in use in pilots, early adopters are beginning to realize that the development of AVs will be able to bridge many existing gaps. This is what happens when the leading solution providers build on their strengths. in Siemens’ case, their Xcelerator solution portfolio, which includes Teamcenter as the collaboration and data management backbone, provides the necessary tools and openness to enable customers to accelerate learning and enhancement cycles. CIMdata looks forward to what comes next.

[1] Research for this commentary was partially supported by Siemens Digital Industries Software.

[2] Go to https://www.cimdata.com/en/resources/complimentary-reports-research/white-papers see 21 July 2021 eBook “Autonomous Vehicle Development Requires Closed Loop Solutions

[3] https://en.wikipedia.org/wiki/Arcadia_(engineering)

[4] https://en.wikipedia.org/wiki/DevOps

[5] https://www.scaledagileframework.com/

[6] https://www.cimdata.com/en/resources/complimentary-reports-research/commentaries/item/16341-a-broad-approach-to-quality-management-commentary

[7] Go to https://www.cimdata.com/en/resources/complimentary-reports-research/white-papers and see 24 November 2020 eBook “Driving the Change for the Future of Automotive Development”

[8] https://www.cimdata.com/en/resources/complimentary-reports-research/commentaries/item/16725-siemens-making-the-digital-twin-executable-predictively-aligning-its-real-world-counterpart-highlight