Key takeaways:

- Information and Operational Technologies (IT and OT) provide different, complementary capabilities essential to every business.

- IT and OT integration used to be difficult because legacy applications were developed, managed, and used separately, but modern technology and solutions make it much easier to integrate IT and OT.

- Integrating selected capabilities within these two domains can deliver significant improvements in business performance by improving data quality and reducing time to find needed information.

- Mendix and MindSphere solutions from Siemens Xcelerator portfolio provide one way to achieve flexible, adaptable, and sustainable integration of IT and OT capabilities.

Introduction

Manufacturing enterprises in every industry are working in complex, fast changing times. They are under continuous pressure to evolve and improve how they operate and are being challenged to develop, produce, and service increasingly more personalized, complex, smarter, connected, and eco-friendly products. Additionally, industry initiatives (e.g., Industry 4.0) are driving higher levels of automation of traditional manufacturing and industrial practices, through the use of modern smart technology. Addressing these challenges requires companies to digitally transform themselves and how they work. Companies must integrate information from more sources across the product and production lifecycles so they can make faster, better informed business decisions.[1]

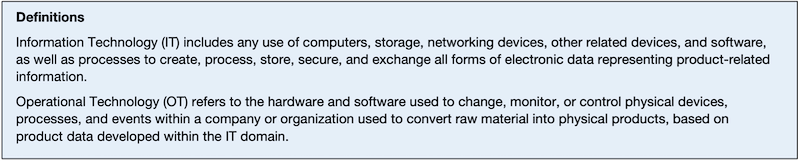

In a manufacturing enterprise, product design and development and product manufacturing environments complement and define each other. Product design impacts how a product must be manufactured (e.g., machine tools, materials, and processes), while the capabilities and performance of the manufacturing environment establish constraints on design parameters (e.g., tolerances, supplied components). Modern product design and development is primarily a subset of the enterprise Information Technology environment consisting of software tools such as 3D modeling, simulation and analysis, software development, process planning, and electrical/electronic design, as well as the related data management and collaboration applications. Product manufacturing manages the operation of physical processes and the machinery and workers that carry them out—primarily an Operational Technology environment.

As part of their digital transformation, companies need to dissolve the boundaries between their IT and OT solutions and other critical enterprise applications. Users and systems in both domains need to be able to easily connect to, and transfer/transform data from diverse repositories into a form appropriate for their intended use. This blending of information across domains is called IT/OT convergence. IT/OT convergence connects IT systems with OT systems, allowing them to share information with each other. IT/OT convergence is a key driver for Industry 4.0; the combined data and contextual understanding enhances the value these systems can deliver to a business.

Today’s smart, connected devices, machines, and systems (and workers) are providing product, production, and service performance data in near-real time that can be consumed in both operational (MES, service, etc.) and informational (design, engineering, process planning, supply chain) applications for improved business performance.

However, IT systems can include middleware and other integrations built on brittle (difficult to maintain) code, that do not have needed connectivity with other systems. Before modern architectures and application development solutions became available, it was difficult to update and maintain integrations between IT systems with OT systems.

Companies need modern, easy-to-use development and integration tools that can create the IT/OT convergence required for their specific business needs. These tools must include both IT capabilities (e.g., APIs, microservices, etc.) and OT capabilities (i.e., sensors, controllers and IoT/IIoT connectivity, e.g., smart machine tools).

Siemens Mendix

The Siemens Mendix™ platform is not just a development tool—it is a comprehensive, modern, low-code application development and integration platform. Mendix is designed to make it easy for both business and professional developers to create and deploy personalized applications and processes. Mendix is also architected in a cloud-native microservices-based environment that enables data integration across diverse, distributed information repositories, applications, and platforms spanning both IT and OT domains.

Mendix is an integral part of Siemens’ Xcelerator solution portfolio and the Xcelerator cloud architecture. It is used to integrate, develop, and extend the components of the portfolio and integrate with non-Siemens (in-house and third-party developed) applications and environments. It can also be used as a standalone tool by any company that needs to develop tailored IT and OT applications and integrate data and processes across their extended value chain.

Mendix integration capabilities are effective in helping companies define and create the digital threads and comprehensive digital twins required to support a given business use case, and as part of establishing a modern, digitally driven enterprise. Mendix is cloud-native for easy application development, connectivity, and deployment. Connectors are available for many Siemens solutions and hundreds of non-Siemens solutions, and there is a Mendix app store with both free and paid apps created by its global community of over 100,000 developers.

Key to any application is its ability to connect with data. The Mendix Data Hub is an open, standards-based metadata repository that enables all users to find and explore data resources throughout their connected ecosystem. At the same time, Data Hub Connectors enable enterprises to connect multiple data sources to the Data Hub, populating a catalog and making that data available to developers. Users can connect to other Mendix application data, Siemens Teamcenter, Siemens MindSphere, Siemens Opcenter, SAP, and numerous other common enterprise data sources (including operational data). The Data Hub can also be extended using the eQube Data as a Service solution that has over 60 smart connectors, providing support for industrial data and system integrations such as Teamcenter with SAP. Leveraging Xcelerator’s modern, microservices-based architecture, the Mendix Data Hub and its connectors provide a foundation upon which to build and evolve applications and integrations that enable IT/OT convergence.

Siemens MindSphere

MindSphere, Siemens’ industrial IoT as a service solution within the Xcelerator portfolio, manages and connects machines, plants, and systems and powers IoT solutions from the edge to the cloud. It provides connectivity to data and advanced analytics services that enable manufacturers to understand that data by leveraging reduced-order simulation models, modern analysis capabilities for predictive learning, and advanced analytical capabilities.

The MindSphere edge-to-cloud asset connectivity capabilities enable asset performance analysis, rapid and informed operational and service decisions, and autonomous actions to be taken by devices directly. MindSphere Analytics Services provide basic and advanced APIs for time series data that can support calculations related to KPIs, signal processing, trend prediction, and anomaly identification. From a product lifecycle perspective, IT/OT convergence is enabled with MindSphere through its extensive connectivity capabilities across the extended product lifecycle ecosystem (such as with Teamcenter). For example, machine tool data that is used to analyze and manage device performance can also be used in the design environment to improve the design of new products. MindSphere’s connectivity also allows data contextualization so information from enterprise systems can be analyzed and made sense of with machine learning and artificial intelligence.

Mendix and MindSphere: Working Together

Mendix and MindSphere are integral parts of Siemens’ Xcelerator portfolio. Working together they enable businesses to create innovative solutions that connect extended value chain ecosystems incorporating any device, from any location, on any cloud platform.

With this combination, companies can more easily create comprehensive feedback loops among product development, supply chain, production operations, service/maintenance, and many other business workflows and digital threads. Mendix and MindSphere support using critical intelligence from edge devices to be part of the data and information feedback loops, analysis, decision making and action taking. Closing information loops in this way also enables companies to create and leverage comprehensive digital twins of their products as well as their production and service processes.

Siemens provides numerous pre-built connectors for common tools and data sources used by businesses (e.g., Siemens Teamcenter, SAP ERP, IBM Maximo). Working together, Mendix and MindSphere empower the convergence of IT and OT in specific use cases by providing a bridge to connect previously siloed OT data with the data being generated by IT systems. Combining and contextualizing IT and OT data gives a company the ability to extract new insights and provides a huge opportunity to increase efficiency, productivity, and competitive advantage. Furthermore, such pre-built connectors in the Xcelerator portfolio speed solution development and enable citizen and professional developers to focus on solving business problems rather than dealing with non-core IT issues.

Conclusion

Maintaining competitiveness requires continuous adaptability, improvement, and innovation. While technology has been used in industry for decades, it historically has operated in silos across the enterprise: IT to support skilled workers in the business domain and OT to support those in production operations. In recent years, companies have started to integrate the silos to improve business performance. This task has been made easier thanks to modern technology architectures and configurable solution sets.

Siemens is at the forefront of this technology shift. Mendix and MindSphere, two key solutions within the Siemens Xcelerator portfolio, can enable IT/OT convergence in many scenarios. Mendix is used to develop for-purpose, personalized applications that leverage its data integration capabilities. MindSphere brings batch or real-time production data to the enterprise. CIMdata has been following the evolution and expanding integration of these solutions. We continue to be impressed with Siemens’ vision and execution. Industrial companies that strive to grow and improve should review Siemens’ Xcelerator portfolio and specifically consider Mendix and MindSphere to support their IT/OT integration and digital transformation requirements.

[1] Research for this commentary was partially supported by Siemens Digital Industries Software.