Key takeaways:

- The convergence of Simulation, Artificial Intelligence, and High-Performance Computing enables the cost-effective use of predictive digital twins in a wide range of industrial applications across entire product lifecycles.

- IT, computational science technologies, and cloud computing accelerate IoT initiatives.

- Simulation and meaningful models are being adopted at an accelerated pace in part due to technology convergence and in part due to the pandemic driven need to find better, safer ways of working.

- Altair continues their annual Future.Industry virtual conference’s focus to explore “Future of” macro trends and technologies. Together with industry and academic thought-leaders, the conference highlighted the accelerating and growing convergence of data analytics, computational science, and cloud HPC technologies and their relevance to product and process innovation, academic instruction, tomorrow’s innovators, and society.

- An annual survey conducted by CIMdata in collaboration with Altair explored the role of these key trends and their growing impact today as well as in the future, with a trend analysis comparing 2020 results with 2021 results.

Pandemic Accelerated the Need for Change

In 2020, CIMdata and Altair surveyed over 350 participants from management and engineering ranks to understand how converging technologies were enabling the future. The summary of that survey and its insights were published in a CIMdata commentary in December 2020.[1] Altair and CIMdata decided to repeat this survey in 2021, with a few additional questions regarding the pandemic, to assess whether the trends identified in 2020 continue as the pandemic rages. With over 500 participants, and a shift towards more practitioners, the trends not only continue, but have accelerated. The increased survey population involves smaller companies who are not only aware of digital twins but have embraced them to lead to new ways of working remotely.[2]

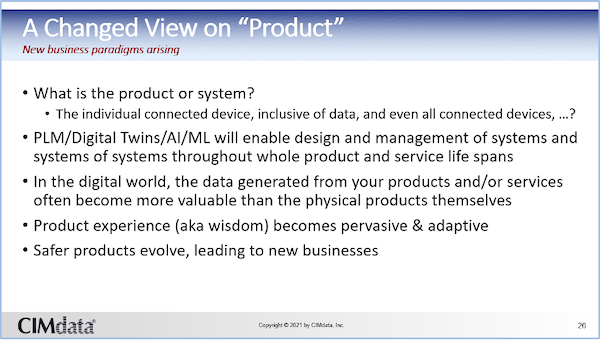

Safely working during this pandemic has been a challenge to us all. The convergence of technologies to explore virtual representations easily has enabled work to continue, even when it must be physically remote. In fact, the impact to companies’ revenues is less than expected and really enabled by pervasive computing, simulation technologies, and virtual work capabilities. Digital twins kept meaningful with the latest sensed data, often from real usages, are no longer just a hypothesis or ideal. Rather the convergence of technologies is making it affordable and critical for a company’s future business. Even the notion of what a product might become is changing as the data sensed becomes as valuable as the manufactured product. This is leading to new kinds of businesses. At the Future.Industry 2021 event, CIMdata presented the survey findings[3] and Figure 3 is the last conclusion slide from that webinar.

Figure 1—2021 Future.Industry Survey Summary—A Changed View on “Product”

Altair understands the need to move beyond physical product testing, both verification and validation. Their thought leaders have embraced data sciences and the commoditization of HPC to realize that digital twins in 4D, 3D plus motion and thermal, provide for richer, more meaningful simulations of a product. As more insights are measured and acquired from actual usage, these digital twins are adjusted to new knowns. This in turn can lead to more robust products, even upgraded after the original mass production. These capabilities will allow companies to use simulation technologies more broadly as their competitive landscapes morph. Increasing product complexity of “smart, connected” cyber-physical systems (hardware, electronics, software, sensors, controls, biological/chemical, etc.) requires integrated multi-disciplinary capabilities for cross-domain design, simulation, analysis, test, and optimization augmented by big data analytics and AI/ML.

Key Results and Findings from CIMdata/Altair 2021 Survey

While Altair is known primarily for being an engineering modeling and simulation company, they have expanded their product scope and customer base significantly over the past decade into complimentary technologies in material data, conceptual design, manufacturability assessment, scalable high-performance computing, big data analytics, and physics-based simulation enhanced via the application of AI/ML technologies. As a result, the attendees of the Future.Industry virtual event were a diverse group spanning the engineering, IT, and computational sciences domains with a balanced representation of both management and technical practitioners. In 2021, the market trends survey was repeated with several identical questions from the 2020 survey, and a few new questions concerning the ongoing pandemic.

CIMdata collaborated with Altair senior staff to refine and repeat that market research survey. CIMdata also conducted the same survey with a subset of its own industry contacts. Besides gathering background information on the respondents (title/role, industry, geography, size of company by revenues, number of employees, number of engineers), the survey posed questions covering the individual’s perspective on the current and future adoption of key technologies across the engineering product lifecycle such as AI/ML, predictive analytics, physics-based simulation, and digital twins. The impact of the COVID-19 pandemic on business practices was expanded. A total of over 500 survey responses were received and analyzed. A shift to smaller enterprises was noted and the effect this had on digital twin adoption and the pace of acceptance with AI/ML was noted. The responses by industry segment and size of organization were in line with the overall engineering software industry profile based on CIMdata’s experience with performing similar PLM market surveys for many years. The broader population was welcome and in CIMdata’s opinion is a reflection of awareness and adoption of broader uses of simulation.

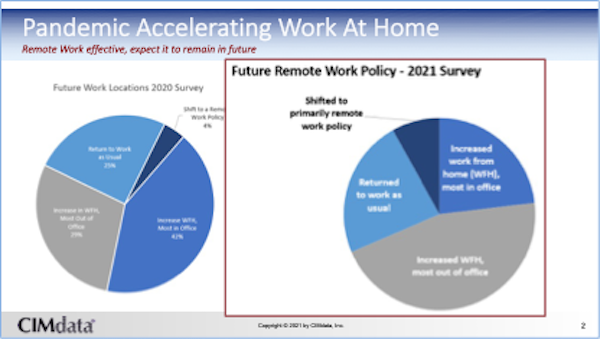

Since the global pandemic continues to profoundly impact our world throughout 2021, we’ll address those results first (see Figure 2). In 2020 we identified the future work locations after the pandemic subsides and 67% expected most of the work to be back in the office. After another year of working remotely, now the survey says < 50% will be in office. In just a year, as businesses remained viable, a significant shift in remote working acceptance has occurred. In fact, policies around encouraging remote work (aka work from home (WFH)) are accelerating.

Figure 2—The Impact of the COVID-19 Pandemic (2020 vs. 2021 Survey Response)

A comparative analysis of the technology trend results, and selected charts are provided below. When answer percentages are shown, the 2021 results are first, followed by the 2020 results in parentheses. Using figure 2, “Increased WFH, most out of office” is 45% (29%), a 16% increase working out of office. “Increased WFH, most in office” is 23% (42%), a 19% decrease for in office work.

Data Analytics, AI, and ML

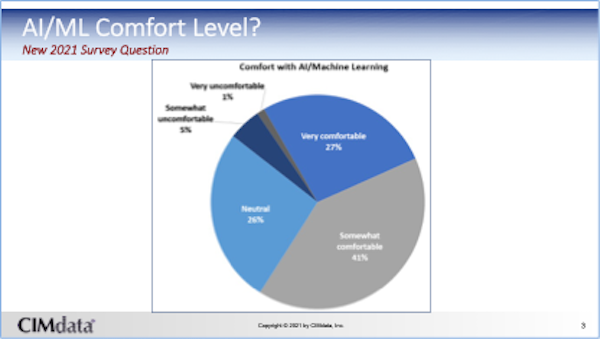

Not surprisingly, the use of data analytics and AI/ML will play a much greater role in providing business and engineering insights going forward. Awareness and comfort in the technology are improving. A new survey question for 2021 examined the comfort level of the participants. Figure 3 shows growing awareness and comfort.

Figure 3—Comfort with AI/ML

The use of mature AI/ML applications in decision making is expected to grow from less than 1% today to approximately 21% within 5 years. The development and use of early-stage AI/ML apps are estimated to grow from less than 16% today to up to 24% within 5 years. Given the broader survey population, this is a very promising trend, increasing faster than what was measured in the 2020 survey.

Cloud

The broader survey population has similar predictions for cloud adoption in 2021 as they did in 2020, with lower current cloud-based practices accelerating to slightly more in five years. The survey posed the question: How aggressively has your company embraced moving data analytics and simulation activities to the cloud? Participants predicted that their company’s usage of data analytics and simulation tools in the cloud would be increasing from 10% (~15%) today to 29% (35%) in the cloud over 5 years, with 31% (30%) used in a hybrid cloud/on-premises environment. Participants forecast that the remaining 39% (35%) of usage would remain mostly or all on-premises.

Smart, Connected Products and IoT

As the world continues to transition to smart, connected products, we asked the respondents how linked their company’s IoT strategy is to their mainstream product development activities. While only 17% stated that these strategies were tightly linked today, they predict 57% of IoT and product strategies would be either tightly linked or coupled within 5 years, no change from the 2020 survey. Given the broader audience, this tells us more industries are not only aware of IoT benefits, but the majority are planning on it for the future.

Digital Twins

There are many types of digital twins that span the entire enterprise, including not only product development and engineering functions but also business and financial functions as well as manufacturing and in-service operations. To date, data-driven only digital twins (i.e., physical asset data is used but is not directly connected to physics-based models of the asset) have been the dominant application of IoT, data analytics, AI/ML, and digital twin technologies.

While almost (50%) of the respondents in 2020 indicated that they were investigating the use of digital twins, in 2021 41% are piloting or in production with some sort of digital twin, while an additional 44% are actively investigating digital twin applications. In five years, they predict 70% pilot or production use, an increase over the 2020 survey of 16%—just one year later with a broader population. This is a clear acceleration in making digital twins instrumental to product development and operations.

The digital twin functional areas where the respondents expected the greatest business impact within the next 5 years were as follows (ranked in order of % of responses):

- Manufacturing 22% (24%)

- Maintenance 18% (14%) {up two}

- Physics-Based Engineering 18% (21%) {up one}

- Operations 17% (12%) {up one}

- Engineering Data Analytics 17% (21%) {down three}

- Financial 8% (5%)

It is interesting to note the changes (the 2020 results are in parentheses), partly driven by the increased sample size and industry segments, as well as likely driven by broadened understanding of how digital twins are more useful. The braces point out the shift up or down the ranked list with 2021 compared to 2020 respondents’ rankings.

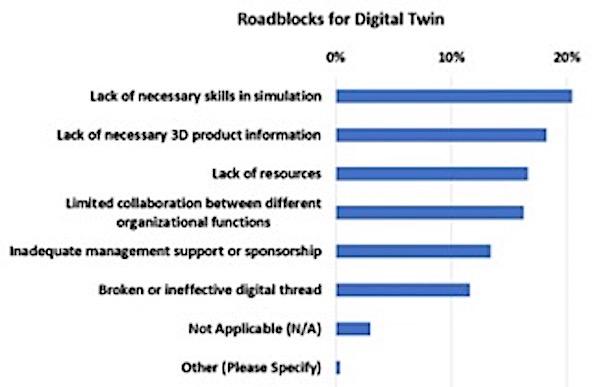

Respondents identified on average 2 to 3 types of digital twins’ usage. Just a few years ago, most engineers identified a single digital twin as a virtual, static assembly or mockup for design reviews. Now they identify many more types of digital twins supporting all kinds of product decisions, many beyond design. These are clear indicators that digital twins have arrived and are being enhanced to improve many decisions. Figure 4 summarizes roadblocks to broader application of digital twins as identified in the new 2021 survey—the constraint is becoming more human related (skills, collaboration, and time) rather than technology related (compute resources).

Figure 4—Organizational Roadblocks to Achieving a Digital Twin Vision

For those interested in more information on the CIMdata survey questions and the results, look at the 2021 Future.Industry webinar, How Key Technologies are Converging for a Smarter, More Connected World[4] by CIMdata Executive Consultant, Craig A Brown. Still have questions, please contact CIMdata at info@cimdata.com.

Conclusion

CIMdata believes there is an acceleration in the adoption of IoT, digital twin, IT/data analytics, and AI/ML technologies with respect to the design, development, manufacture, and sustainment of complex cyber-physical systems (i.e., smart, connected products). As the survey results indicate, there is still work to be done but there is also great opportunity and tangible business impact to be realized by industry in effectively implementing these emerging technologies in engineering and product development as well as other domains such as manufacturing, quality assurance, maintenance, and in-service operations.

To date, the impact of COVID-19 on engineering software and services market growth appears to have been less than was feared and certainly less than the major economic disruption/depression of 2008-2009. In fact, the pandemic has been a positive business factor for selected industry segments and agile companies that were positioned to respond rapidly to the changing global market dynamics and customer needs. The business challenge is enabling smart people, augmented by the effective use of digital technologies, to achieve the business objectives of private enterprise while benefiting society. Business agility, creativity, and product innovation will always prevail.

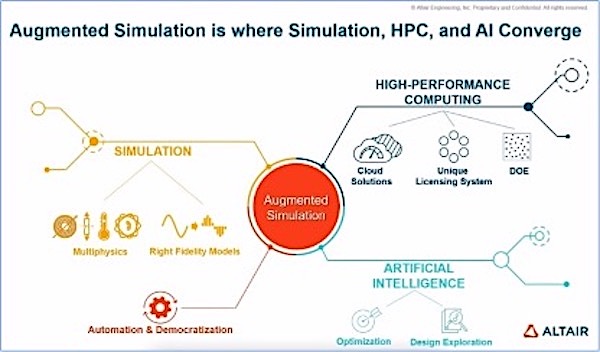

Figure 5—Dr. Uwe Schramm’s Conclusion

Dr. Uwe Schramm, Altair’s CTO, gave us a summary of augmented simulation being where simulation, HPC, and AI converge, at the 2021 Future.Industry conference, see Figure 5—the last slide in his keynote presentation.[5] Altair is investing heavily in these areas as a cornerstone of its business vision and strategy. We commented on the forward thinking and applauded the AI/ML focus at Altair in 2019.[6] Two years later, with the pandemic as a challenge and a catalyst, Altair’s focus has proven just how wise their strategy has been.

Year 2 of the technology convergence survey confirms an acceleration is occurring and the early adopters are getting past their concerns with the converging technologies and embracing just how radical this can change their businesses. CIMdata looks forward to further progress at Altair and their customers in realizing the business impact of a smarter, more connected world. Look for the survey next year as we continue this research in 2022.

[1] https://www.cimdata.com/en/resources/complimentary-reports-research/commentaries/item/14706-technology-convergence-for-a-smarter-more-connected-world-market-trends-commentary

[2] Research for this commentary was partially supported by Altair

[3] https://www.altair.com/resource/how-key-technologies-are-converging-for-a-smarter-more-connected-world

[4] https://www.altair.com/resource/how-key-technologies-are-converging-for-a-smarter-more-connected-world

[5] https://www.altair.com/resource/path-to-augmented-simulation

[6] https://www.cimdata.com/en/resources/complimentary-reports-research/commentaries/item/12998-altair-continues-to-expand-solution-portfolio-for-simulation-and-analysis-of-mechatronics-systems-commentary