Key takeaways:

- In response to regulatory requirements, customer demand, and investor demand sustainability is becoming a strategic objective at companies.

- While sustainability goals and targets get the headlines, achieving them in practice is difficult. Although operational issues tend to get the focus, depending on the product, up to 80% of the sustainability impact relates to engineering design decisions.

- While current regulations are strict, as climate change concerns grow, C02 output will get increasing scrutiny from consumers, investors, regulatory bodies, and employees.

- Solutions that capture requirements, define features to satisfy requirements, verify the features are implemented, and systematically track achievement of goals and targets are required to ensure sustainability principals are core to product ideation and realization.

- Accenture has put deep thought into their sustainability approach and is enabling it within their Industry X - Engineering and R&D Digitization practice to ensure customers have solutions to meet current requirements and adapt to future needs.

Introduction

Sustainability, and especially the impact of CO2 output are significant concerns in company boardrooms. Regulators, customers, and investors are driving companies to reduce their CO2 output and other environmental impacts while maintaining their business performance. This is a complex and difficult problem to solve.[1]

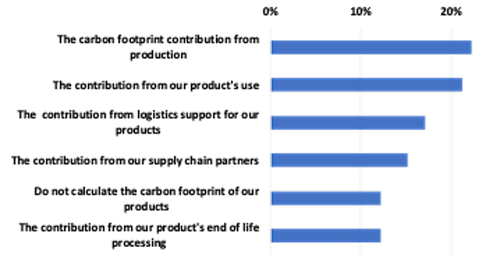

During CIMdata’s recent PLM Market and Industry Forum, focused on sustainability, we presented research results on the topic. As part of that research, we surveyed industrial companies to find out if they would like to have the ability added to their solution so they could calculate the full CO2 footprint of their product. 71% responded “Yes.” We then asked which elements are currently included in their carbon calculation. Figure 1 shows the responses.

Figure 1―Elements are Included in Calculating Products’ Carbon Footprint

(From CIMdata Research)

If these responses are typical of most industrial companies, CIMdata believes there is a lack of emphasis on this topic at this point in time. 22% or fewer of the respondents include each item in their calculation. While production and product use are often the largest contributors, other items can be significant, especially when considering that 71% of the respondents want to calculate the full CO2 footprint. This indicates that there is a big opportunity to institutionalize carbon calculation methodology and implement sustainability tools and processes across the organizations. Without proper strategies, processes, information, and tools generating appropriate carbon footprint information companies often end up with an unrepeatable scramble. Developing products that are designed and manufactured to produce less carbon during creation, use, and disposal maximizes sustainability, however, is difficult to achieve.

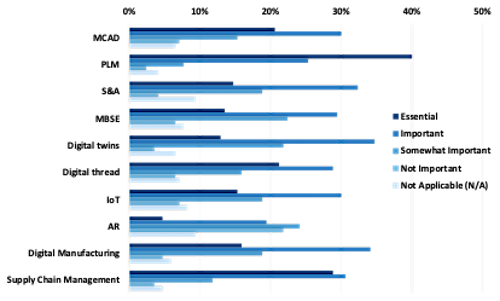

We also asked the respondents to identify the level of importance of PLM technologies when calculating a product’s carbon footprint. The results are shown in Figure 2. A key takeaway is that most of the technologies are of high importance (defined as the sum of essential and important responses totaling greater than 50%). A second key takeaway is that achieving the innovation needed to address sustainability, simulation and analysis (S&A) and model-based systems engineering (MBSE) have the most untapped potential, as they both enable prediction from virtual models.

Figure 2– Importance of the Range of Technologies, Processes, and Capabilities Available that can Help Enable Sustainability Efforts

(From CIMdata Research)

In 2021 Accenture partnered with Dassault Systèmes on research that resulted in a report titled Accelerating Sustainability With Virtual Twins.[2] <https://www.accenture.com/us-en/blogs/industry-digitization/accelerating-sustainability-with-virtual-twins> In the report researchers focused on calculating what impact virtual twins (more usually called digital twins) could have on carbon footprints in various industries. Overall, they found that digital twins could create benefits of $1.3T in economic value and a reduction of 7.5 Gigatons (Gt) of CO2 emissions by 2030. Up to 80% of the sustainability impact relates to engineering design[3] decisions so improvements in decision making tools will have a positive impact. CIMdata’s research shows that there is an emerging understanding within industry that PLM technologies including digital twins can impact sustainability.

Solution Path

There is an old quote: “you can’t control what you don’t measure.” It certainly applies to sustainability; to maximize sustainability it must be measured. The common categories of measurement include raw material extraction, manufacturing, distribution, use, and disposal/recycling which at a high level describe a system model.

Lifecycle Assessments (LCA)

Life Cycle Assessment (LCA) development began in the late 1960s and evolved over the decades. It initially focused on energy consumption in packaging and over time added diverse categories including global warming, acidification, eutrophication,[4] and eco and human toxicity. The lifecycle approach evolved from the recognition that not only were there different types of sustainability impacts, but they also occurred at different points of the lifecycle (resource extraction, manufacturing, operation, and end of life). The LCA approach is the commonly used sustainability measurement methodology based on the ISO 14000 series of standards and results are well accepted within industry. While LCA can be used to derive total impacts, it is a framework similar to ISO 9000, so it is not an out-of-the-box solution. Furthermore, unless it is integrated into design and modeling solutions it becomes more of a report than a predictive design tool.

To implement a sustainability program the first step is to determine the scope to be assessed. For example, automobiles have their largest impact when they are used, so fuel economy is a critical parameter that also impacts CO2 production which impacts global warming. An inventory of impacts is then extracted from government and commercial databases which are then processed manually or by software applications. The results are then interpreted and reported.

Over the past few years standalone LCA solutions have been integrated with PLM solutions, making it easier to measure, track, and assess product sustainability.

PLM and MBSE

To provide a solution to effectively manage sustainability a complex environment is required. A PLM solution is the foundation as it captures and manages the data, configurations, and processes that describe the product. Managing the product configuration provides the context to understand both simulation results and IoT time-series results from physical instances. Once simulation data is properly managed, MBSE provides the capability to do effective trade studies that enable the design team to optimize the product as we noted in a recent commentary[5] about applying MBSE to the development of a robotic airport luggage carrier system.

Digital Twins

The application of digital twins provides new opportunities to improve the optimization process. The digital thread between the physical twin and digital twin enabled by IoT can support many use cases, but two critical ones are product use optimization and product improvement. The IoT time-series data can be incorporated into simulations and system models to close the loop and validate early calculations done on virtual models and provide baseline data for optimization studies.

Digital twins enable companies to develop products in short timeframes, at higher quality, and lower cost. They do this by linking the product configuration to the product behavior described by simulation and physical testing. The results can be consumed in the context of the configuration or by artificial intelligence (AI) algorithms enabling faster, more accurate decisions.

While this is simple in concept, getting processes, data, and technology aligned so the product development process is repeatable usually requires a digital transformation. A critical aspect companies often fail to emphasize is organizational change management (OCM). Adding a significant new objective like sustainably is a major organizational change, and to ensure effective adoption, workers need education and support to understand why they need to change, and training and support about what they need to do differently.

Accenture’s Approach

Accenture provides full lifecycle support for companies that want to improve sustainability within their products and operations. They are currently working with clients to develop a next generation approach to managing sustainability. Rather than create reports that provide a static LCA score, the solution will provide real-time recommendations to design team members during digital twin development that lead to better decisions and improved sustainability. Technologies being investigated include approaches where an engineer enters requirements and an artificial intelligence (AI) algorithm proposes the optimal design choice. This works similar to how generative design algorithms function.

The key elements to bring sustainability into the digital twin are a digital thread, the end-to-end connectivity of data and processes across the lifecycle, and AI algorithms that can generate more sustainable design solutions by leveraging simulation results. Accenture is using a MBSE approach to create digital continuity in the background to develop their solution bringing sustainability to the front of the lifecycle where it belongs. As engineers are provided with design alternatives by the system, they can see the impact of their decision in real or near real-time improving decision quality. This technology is already working today for other product requirements such as cost and performance so extending these principles to support sustainability is even more a systems and data integration issue. By developing trade studies using models and making decisions early based on model results, sustainability can be optimized.

Accenture has teams skilled in all the major solutions within the PLM marketplace, other enterprise solution domains such as ERP and CRM, and is recognized for their management consulting and OCM expertise. The breadth of their services and scale of their organization enables them to go far beyond product innovation platforms used to support PLM and support an enterprise platform i.e., a platform of platforms that support all enterprise requirements.

Conclusion

The pressures on companies today are enormous and sustainability has emerged as a big issue that companies must address. CIMdata believes the best way to make progress is with product and process innovation. To effectively address sustainability and especially CO2 output, better decisions need to be made during the product design phase where they can have large impacts with minimal cost.

To have a real impact sustainability decision support can’t be simply tacked on. It needs to be pervasive within the product development process, related tools, and organizational mindset. MBSE is one possible solution, that provides a proven approach to product optimization, and can incorporate sustainability to enable optimization, but most current solutions especially those focused on LCA operate as standalone solutions making optimization difficult. To successfully implement a sustainability program, companies need a strong partner to address people, process, and technology challenges.

Accenture is developing sustainability solutions that leverage MBSE and AI to dynamically guide engineers and designers on how to maximize sustainability during product development. Beyond technology, Accenture has management consulting tools and processes to adapt organization structures to incorporate sustainability practices that will pass external scrutiny and be truly impactful on sustainability and CO2 output reduction. Their management consulting and systems integration skills enable them to digitalize strategy and processes using the latest technology at scale. Companies looking to up their sustainability game and ensure it operates at scale should contact Accenture.

[1] Research for this commentary was partially supported by Accenture.

[2] https://www.accenture.com/us-en/blogs/industry-digitization/accelerating-sustainability-with-virtual-twins

[3] https://joint-research-centre.ec.europa.eu/scientific-activities-z/sustainable-product-policy_en

[4] Eutrophication: excessive richness of nutrients in a lake or other body of water, frequently due to runoff from the land, which causes a dense growth of plant life and death of animal life from lack of oxygen. From Google on-line dictionary.

[5] https://www.cimdata.com/en/resources/complimentary-reports-research/commentaries/item/16812-accenture-develops-mbse-practice-helping-clients-transform-to-manage-growing-product-complexities-commentary