Key takeaways:

- While current implementation and near-term investments in the digital thread are greatest in product development, it is being extended more broadly throughout the lifecycle to support product production and product conceptualization.

- The complexity of impacts on the organizational and cultural resistance are considered major inhibitors of digital thread adoption.

- Industrial organizations need tailored education and expert support services to assist with strategy and execution to achieve the value potential of the digital thread.

During the recent PLM Road Map™ & PDT North America 2022 conference,[1] attendees were asked to complete a survey to indicate their current state and plans for implementing the digital thread within their companies. The survey explored this topic in three dimensions:

- Where in the product lifecycle the digital thread is implemented and delivering value

- Product structure views that are linked together as a digital thread

- Principal inhibitors to formulating and executing a digital thread strategy

A total of twenty-five, primarily end-user, attendees completed the survey, providing a statistically significant sample.

Respondents were first presented with an illustration of product lifecycle stages and asked to indicate where in the lifecycle (see Figure 1) the digital thread is implemented and delivering value within their companies.

Figure 1―ISO 15288 System Lifecycle

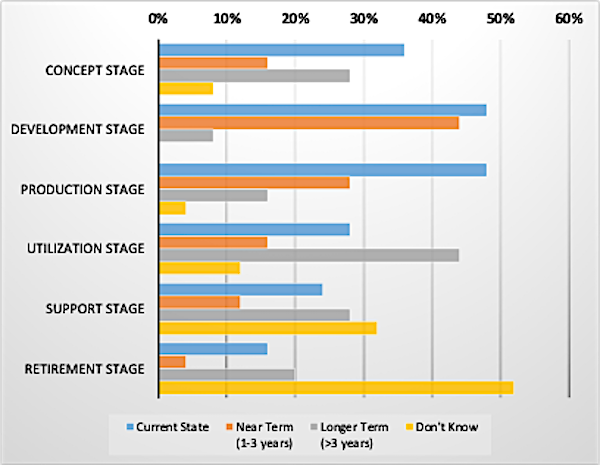

The status of digital thread as currently implemented and as planned within the various lifecycle stages is shown in Figure 2.

Figure 2―Where in the Product Lifecycle the Digital Thread is Implemented and Delivering Value Currently and As Planned

According to the survey respondents, current implementations and near-term investments in digital thread is greatest in the Development Stage, followed closely by the Production Stage, and then by the Concept Stage. Longer-term investment is planned for the Utilization Stage and Support Stage. Interestingly, the “Don’t Know” responses increased in stages proportionate to their degree of separation from the Development Stage. This may indicate that digital thread awareness and maturity decrease as lifecycle stages increase in distance from the Development Stage.

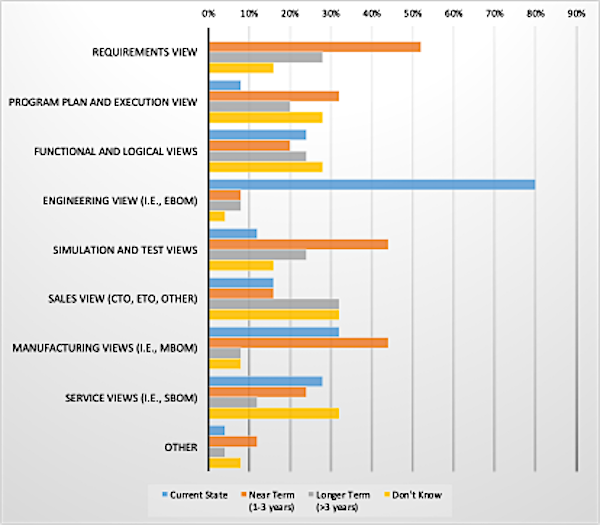

Respondents were next presented with a list of product structure views and asked to indicate which views are linked together as a digital thread currently or in plan within their companies. The results are consolidated and presented in Figure 3.

Figure 3―Product Structure Views that are Linked Together as a Digital Thread Currently and As Planned

Currently, the most prevalent linkages are within the Engineering view, and then between Engineering (i.e., EBOM), Manufacturing (i.e., MBOM), and Service (i.e., SBOM) views. In the near term, plans are to continue investment in linkages between Engineering, Manufacturing, and Service and extend linkages to Requirements, Simulation and Test, and Program Plan and Execution. In the longer term, plans are to extend linkages to Sales and continue investment in linkages between Engineering and Requirements. Within every timeframe, substantial investment is planned for Functional and Logical as the intermediate linkage between Requirements and Engineering.

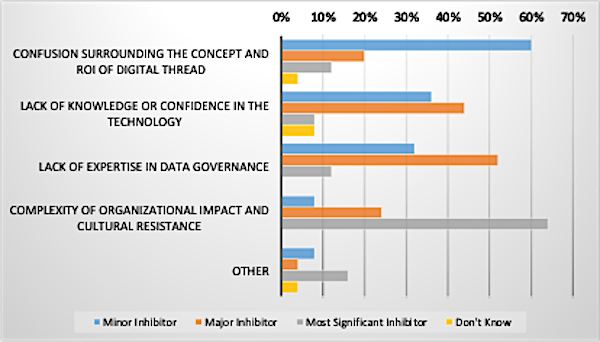

Finally, respondents were asked to weigh in on inhibitors to formulating and executing a digital thread strategy within their companies. They were provided with a list of four possibilities and offered the option to propose others. The respondents’ opinions are presented in Figure 4.

Figure 4― Principal Inhibitors to Formulating and Executing a Digital Thread Strategy

The most significant inhibitor in the view of most respondents (64%) is Complexity of Organizational Impact and Cultural Resistance. Other factors considered major inhibitors by many respondents are Lack of Expertise in Data Governance (52%) and Lack of Knowledge or Confidence in the Technology (44%). Other factors called out by respondents as the most significant inhibitors included “complex technical dependencies,” “massive legacy problem,” and “cost.”

Interestingly, most respondents (60%) did not see Confusion Surrounding the Concept and ROI of Digital Thread as a significant inhibitor. In contrast, there is clearly a need for tailored education and expert support services to assist industrial companies with strategy and execution to achieve the value potential of the digital thread.

Summary Observations

The following key takeaways can be derived from the analysis of the survey results:

- Current implementation and near-term investment in the digital thread is greatest in the Development Stage, followed closely by the Production Stage and then by the Concept Stage.

- The most prevalent digital thread linkages are within the Engineering view, and then between Engineering (i.e., EBOM) and Manufacturing (i.e., MBOM) and Service (i.e., SBOM).

- In the near term, digital thread investment will continue in linkages between Engineering, Manufacturing, and Service, and extending linkages to Requirements, Simulation, and Test, and Program Plan and Execution.

- The most significant inhibitor in the view of most respondents (64%) is Complexity of Organizational Impact and Cultural Resistance.

- Factors considered to be major inhibitors by many respondents are Lack of Expertise in Data Governance (52%) and Lack of Knowledge or Confidence in the Technology (44%).

- There is clearly a need for tailored education and expert support services to assist industrial companies with strategy and execution to achieve the value potential of the digital thread.

[1] PLM Road Map & PDT North America. Tysons Corner, VA, USA. 24-25 May 2022.