Key takeaways:

- The concept of the digital thread has become important to many industries, expanding well beyond its roots in discrete manufacturing.

- The Bill of Material (BOM) is at the core of the digital thread, and the nexus for information that industrial companies want to associate with the BOM as it evolves from idea through life.

- OpenBOM, a recent entrant into the market, offers a cloud-native, multi-tenant solution that helps companies and their value chain partners collaborate around the BOM.

- OpenBOM’s customers have started to expand their use of OpenBOM’s delivered capabilities into use cases more typical of other enterprise software such as ERP and PDM.

Introduction

The concept of product lifecycle management (PLM) emerged in the late 1990s, but manufacturers have managed the lifecycle of their products well before manufacturing at scale began. It was only through the application of digital technology to the product lifecycle, starting in Industry 3.0, through to Industry 4.0 and, some would have you believe, on to Industry 5.0, that managing such an expansive topic became more feasible. CIMdata has worked in this market space since our inception in 1983 and has long had a PLM definition of our own, one that spans the end-to-end lifecycle from idea through life.

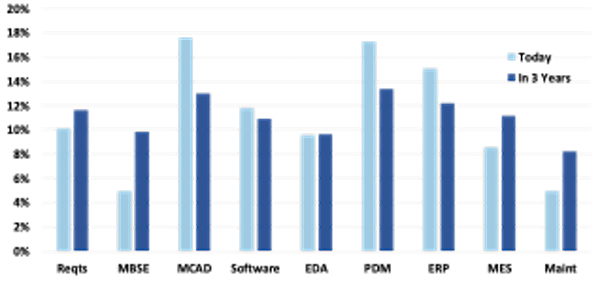

For more than twenty years, CIMdata has spoken about a bill of information (BOI), an expansive, associative virtual data store built around the bill of material (BOM), which evolves from idea through life, and includes associated information that supports lifecycle processes, e.g., documented product requirements, early and final versions of the design, assembly and maintenance instructions, and virtual and physical test results. These are but a few types of information that manufacturing companies want to manage as part of their digital thread, which builds on the BOI concept and has gained credibility in many industrial sectors. In a recent survey, CIMdata asked industrial respondents about their plans to manage disparate knowledge as part of their digital thread.[1] Figure 1 represents the current state of the digital thread at our industrial respondents and their expansion plans over the next three years. Mechanical computer-aided design (MCAD) is often managed using product data management (PDM) solutions, and both rated highly. And the transition of the engineering BOM (eBOM) to the manufacturing BOM (mBOM) usually managed in an enterprise resource planning (ERP) solution, was also highly rated.

However, when asked what the plan to include in their digital thread beyond the fixed choices shown in Figure 1 many new applications were cited. Enterprise mainstays like Customer Relationship Management (CRM) and Human Capital Management (HCM) were important to some respondents. It is also not surprising that tying in the Internet of Things/Industrial Internet of Things (IoT/IIoT) was listed as other CIMdata research shows its growing importance to support smart, connected products in numerous industrial segments. Support for compliance and regulations, particularly on sustainability, was also seen as crucial.

Figure 1―Evolving the Digital Thread Over Time

But with all of this technology available, what do many companies use to manage their BOMs? Microsoft Excel wins hands down, and is used by small shops and some of the world’s largest corporations to manage their various BOM structures (e.g., eBOM, mBOM, and sBOM―service BOM). It is seen as free and easy to use and adaptable to a range of needs. While this is true, it results in brittle processes and disconnected data sources that are only as good as the spreadsheets used to power them and the discipline of those that use them.

OpenBOM: Expanding its Lifecycle Capabilities

Enter OpenBOM, a cloud-native, multi-tenant, collaborative lifecycle management application that is simple to use (offering many constructs similar to Microsoft Excel) and has a substantial list of customers ranging from small shops to large corporations. OpenBOM was conceived to better support the collaborative creation and management of the evolving BOM across value chain networks.

As stated above, the central construct in a digital thread is the product’s BOM as it evolves from a concept to a realized product and on through its useful life. As such, OpenBOM is well positioned to enable this critical evolution. Their current offering spans use cases typically enabled by PDM, PLM, and ERP solutions. But some customer deployments are using OpenBOM for concept BOM development, pushing it upstream in the product lifecycle, and others are working with sBOMs focused on the as-maintained BOM. Many would describe these sBOM use cases as being supported by offerings in several application segments, including enterprise asset management (EAM); maintenance, repair, and overhaul (MRO); service lifecycle management (SLM); and, to some extent, customer relationship management (CRM). These lifecycle extensions are critical to firms responding to requirements to develop, manufacture, deploy, operate, and maintain smart, connected products. They also help to expand OpenBOM’s addressable market as companies of all sizes, in most industries, are making smart, connected products.

To better understand how OpenBOM and its customers are leveraging their solution to support these expansions, CIMdata spoke with Mr. Oleg Shilovitsky, a co-founder and OpenBOM’s CEO. A summary of our conversation follows.

CIMdata: How does OpenBOM support internal product development collaboration in support of BOM development and management?

Oleg Shilovitsky (OS): Supporting PDM- and PLM-related use cases is the most straightforward thing that we do today. OpenBOM manages items, the BOM, and supports change requests against those data objects. Change approvals can be collaborative, allowing participants to review the actions of others. Users can attach files of different types to managed items. These capabilities are all simplified vs. major legacy offerings. Our customers do not expect that level of complexity and are not typically interested in more complex and expensive solutions. Or they have them in some parts of their business but find that the overhead of using such offerings might not best support their current needs, such as on special projects with demanding timelines.

Earlier this year we expanded our capabilities in collaborative file sharing with the introduction of OpenBOM Drive. It offers a virtual drive as a workspace to manage groups of files. Users work in a single drive, and it does not require checking files in or out as with other systems. OpenBOM connects files with design information to items and BOMs, creating a thread between design structures and the eBOM.

CIMdata: What about external product development collaboration in support of BOM development and management, some of which might be done with supply chain management (SCM) solutions?

OS: At OpenBOM, we believe that our data model and multi-tenancy helps us better support external product development collaboration as you describe. Today, we have many customers whose teams include internal users, suppliers, contractors, and other roles.

We believe that a big differentiator for OpenBOM in managing the digital thread is our multi-tenant approach, which enables some use cases that others cannot readily support. OpenBOM has a data network layer that allows multiple individual OpenBOM users or companies to share data. Traditional single-tenant systems can share information as long as all users are added to the same instance of the system. If you have multiple single-tenant systems, the only way to share data is to export it from one system and import it into another.

When tiers of suppliers and other subcontractors are brought into most systems, they are not satisfied having their actions and information managed by an administrator. Using OpenBOM, they can act as their own administrator. They can use OpenBOM as their development system, extending system logic and rules specific to them. We believe that other PLM systems cannot support this use case. When our customers ask if they can add someone to their implementation, they quickly realize that they can add anyone they want. But it is better for each participant to have a separate OpenBOM account so that they have more control over their own information.

We are also seeing demand for change processes that can go across multiple companies. OpenBOM offers more granular data access than most solutions. If you want to do a change in a traditional single-tenant system, each party to the change must have an account on that single-tenant system. In OpenBOM, each company (e.g., OEM, supplier, contractor) will have their own account, and can readily access the data needed, subject to the security model in force. You don’t have to share the entire product structure, only the parts of it that are approved to share.

Tomcar, an Israeli company, is developing an ultra-fancy all-terrain vehicle. Before OpenBOM, Tomcar didn’t have a single BOM source for a vehicle, but rather their data was scattered across multiple spreadsheets. Today, they are using OpenBOM to manage the entire vehicle BOM. They leverage our granular data sharing capabilities to provide access to elements of the BOM to their contractors and suppliers, who have their own OpenBOM accounts.

We are now moving to support a multi-view BOM since many customers want to manage the eBOM to mBOM transition. This capability is now in development, and we want to ensure that we deliver a more advanced model that will work with more than eBOM to mBOM. We expect our initial capabilities in this area to be released later in 2022.

CIMdata: CIMdata recently conducted some industrial research showing the growing importance of compliance and sustainability. Can OpenBOM support compliance monitoring based on BOM content and roll up?

OS: OpenBOM offers a very flexible data model. We offer you the user experience of Microsoft Excel, in that you can easily add columns of different data types. New item or instance variants, modeling specific orders, and many other variations are in use by our customers every day. Users can add any attribute, including those required to support WEEE and other compliance requirements. When you make such changes to the data model, it updates instantly to ensure all value chain collaborators are working to the same structure.

One of the most important benefits of our flexible data model is that it supports embedded calculations, formulas, and our rollup mechanism. Dynamic cost rollup is the most widely used. OpenBOM customers are building a variety of analytical models comparing costs of products built using different suppliers, large quantity orders, and other criteria.

The second part of your question, about rolling up information, is more complex. Users come to OpenBOM asking for real-time access to data in OpenBOM. They think that because OpenBOM is “open” they should be able to access anything at any time. But since value chain users often have their own OpenBOM accounts with their own rules and controls, this may not be the case.

We will continue to work with our customers on this important topic.

CIMdata: Moving from engineering into manufacturing requires creating mBOMs and feeding them into one or more ERP solutions used by an organization? How are you supporting this process?

OS: Some customers refer to OpenBOM as “ERP light” as we support use cases more typically enabled by an ERP solution. For examples, customers are using OpenBOM to support inventory management, order planning, and purchasing. Our solution does not currently support continuous planning with specific dates and timelines. It is more for planning on a discrete basis. For example, if the desired stock level is 400, you can review how many are on hand and, if needed, send a purchase order to your suppliers to restock. This works well for small companies that may not have an ERP system or for projects at larger companies that do not want to incur the overhead of using an ERP system.

CIMdata: How is OpenBOM being used to support BOM definition and collaboration during the purchasing process?

OS: One example is when customers are using OpenBOM to support the prototyping process. They often need more integration with their ERP system, if they have one, since it usually supports purchasing. For smaller firms, we also integrate with QuickBooks and have been getting more requests to link with Xero, a UK-based competitor of QuickBooks.

Fundamentally, OpenBOM supports ERP uses cases in three different ways. Some users are not looking for an ERP system. They might be in an engineering niche business, acting as design contractors or consultants, or they work for a design firm. They do not need an ERP system and use OpenBOM as a complete system for design data and engineering data management.

Small companies often do not have an ERP system and are looking to fill this gap. After getting “ERP sticker shock,” they come back to us and say maybe OpenBOM can do what they need. They use OpenBOM to manage quantity on hand, issue purchase orders, and to support planning. In our experience their pain is more about purchasing than production planning.

In the third case, contract manufacturers are using OpenBOM to support their purchasing efforts.

Many customers want to link OpenBOM with their chosen ERP system. We quickly realized that we cannot integrate with all ERP systems. To better support linking with ERP systems, we created an integration in partnership with NetSuite, a leading cloud-native ERP system that is now part of Oracle. While it may not be the most often used system by our customers and prospects, it did offer a great opportunity to create an end-to-end integration. NetSuite was a good test case, even though it has not enticed a lot of customers to OpenBOM. Creating this integration did give us a lot of visibility and proved our technical approach. Ultimately, we showed that we could support complex processes.

We have also done work with CYCLR, an integration specialist that offers an integration platform. We worked with them to create the needed integration with Xero. We have not yet made that integration commercially available but we have it ready when needed.

CIMdata: Another important BOM connection in the product lifecycle is moving from the mBOM to actually building the product, often supported by manufacturing execution systems (MES). Can OpenBOM be used as a “BOM hub” to feed multiple MES solutions.

OS: This may be happening but at present we do not have a lot of customers to report. We are actively looking at the potential connection with MES systems.

CIMdata: With the emphasis on smart, connected products and executing “product as a service” strategies, many companies are focusing more on the “as-maintained BOM.” How does OpenBOM help define and maintain BOM structures of an installed base of equipment?

OS: Yes, we are getting a lot of requests around this topic. We do have one customer that is using OpenBOM for simple MRO use cases, leveraging OpenBOM to create a serialized BOM and then creating a customer BOM for a specific piece of equipment. In our experience to date, the biggest pain point in this story is the customer not knowing what part to order. Their customers can use this sharable BOM to order maintenance parts.

Serialized BOMs for maintenance often come up in conversation, with much less emphasis on CRM systems. In most cases, the CRM knows what product was sold to a given customer but that information is not usually connected to the actual product configuration sold. For example, we talk about this a lot with industrial equipment companies that use SOLIDWORKS. We do support configurable BOM views in our product today.

CIMdata: Another hot segment is configure-price-quote (CPQ), which can help manufacturing companies better support their sales process by enforcing sale of buildable configurations that are profitable, a big issue for many configure-to-order companies. How can OpenBOM support BOM variants, and the associated rules for CPQ processes and other supporting technologies?

OS: Today, our solution does not support this formally, and has limited support for configurability and product variants. While it does not readily support configuration during the sales process, it can help where OpenBOM customers are creating orders and sending quotations to suppliers. ABB Marine is using OpenBOM as a sales tool to produce real-time sales orders for customers. OpenBOM is also providing the digital infrastructure for companies building connected solutions. For example, E-commerce is using OpenBOM to calculate product prices online based on BOMs leveraging a connection to real-time costing information.

CIMdata: This conversation has focused on use cases that expand OpenBOM’s lifecycle reach. They can all contribute to a company’s digital thread. How does OpenBOM support this broad concept?

OS: OpenBOM believes that the digital thread we are building is the foundation of product data intelligence. OpenBOM uses a graph database (Neo4j) to build a global BOM graph (what CIMdata would call a BOI) that connects information about multiple products, contractors, and suppliers. The graph contains a lot of valuable information about the digital thread. At OpenBOM, the graph database supports our analytical engine that helps manage flexible relationships between data elements and supplies graph analytics that glean intelligence from product lifecycle management data management and processes. We can also leverage graph data science, which provides a way to combine connected data analytics and machine learning (ML) algorithms to help understand the connections in big data to answer critical questions and improve predictions. It includes graph statistics, queries, visualization, graph analytics, and graph-enabled ML. It will help power a range new functions and capabilities in OpenBOM in the future. The graph database allows us to perform a 360 degree analysis of product dependencies on a single supplier or a cost analysis across complex product structures. One of the most popular capabilities of OpenBOM is creating complex product structures from multiple assemblies. Our graph database makes it easier to analyze similar components purchased from multiple suppliers across the many products.

CIMdata: Thanks, Oleg, this has been a very helpful and informative conversation for us and, hopefully, our readers.

Conclusion

The origins of the digital thread concept go back to the original PLM definition. At the core of the digital thread is the BOM, to which other information developed as part of the product lifecycle can be associated. CIMdata research has shown that industrial companies have an expansive view of their digital thread so offerings purported to support the digital thread must be able to support a wide range of data types and use cases that might span enterprise software segments.

OpenBOM, a recent entrant in this market, offers an easy-to-use, cloud-native solution that makes it easy for companies of all sizes to collaborate around the BOM as it evolves from idea through life. While most of OpenBOM’s customers use their solution to support core product design and engineering tasks, OpenBOM is expanding their vision by working with lead customers that want to use the solution in new areas. In this commentary, CIMdata explored a number of these new areas to highlight the opportunities for OpenBOM and their customers to better support their lifecycle needs. A lot of work has been done by the company and their customers and CIMdata was impressed by the range of use cases they can now support. We look forward to learning more about this offering as it evolves.

[1] “Cloud-SaaS Adoption in PLM”, available from https://www.cimdata.com/en/resources/complimentary-reports-research/white-papers, registration required.