Key takeaways:

- The Kubotek Kosmos platform provides the 3D modeling foundation needed for developing specialized applications in the engineering, simulation, and manufacturing domains.

- The Kubotek Kosmos proprietary geometry kernel supports their Validation and Interoperability solutions instrumental in synchronizing supply chain interaction.

Turning the idea of a new, special-purpose application or software tool into reality is fraught with challenges. Developers must face a gauntlet of issues that require specific knowledge in multiple technologies. In the product lifecycle management (PLM) arena, the producers of new applications often require difficult to find knowledge of 3D modeling and graphics. As a result, many turn to the licensing of proven component software as a foundation for their new application. PC Magazine defines component software as “Program modules that are designed to interoperate with each other at runtime[1].”

New application developers must also position their solution to take advantage of the complete market by allowing their application to input product model information from many different design applications in numerous data formats or else lose out on potential revenue. Their application must also support industry standard formats, such as ISO STEP.

Kubotek has mustered their history of supporting the manufacturing supply chain and now rebrands themselves as Kubotek Kosmos to provide an application development platform for special application builders.[2] CIMdata views this new direction for the company as a major turning point that should reinvigorate its position in the market.

Figure 1―Kubotek Kosmos Logo

(Courtesy of Kubotek Kosmos)

The Kubotek Kosmos platform houses the Kosmos 3D geometric kernel whose technology supports geometry with different tolerance levels from many different sources without compromising accuracy by approximating or mapping. Kubotek’s long experience in the manufacturing build-to-print supply chain together with a partnership with Datakit[3] has provided them the knowledge of what is needed to support data movement between suppliers who use a diverse set of tools and to maintain that data without compromise.

Component Software

The PLM industry has long experienced special applications in CAD modeling and CAE simulation which were developed upon component software. Those solution developers were able to focus on their own application expertise while relying on modular components in geometric modeling, constraint solving, and graphics display in order to bring their applications to market faster. Kubotek has also a long heritage in delivering a solution, KeyCreator, to the manufacturing supply chain using component technology.

Now Kubotek has been able to collect and focus that knowhow and offer it to other application developers in the Kubotek Kosmos engineering software development framework. The Kosmos framework provides an advanced suite of multi-platform software components which support development of specialized design applications. Developers working in CAD, CAM, and CAE will find the necessary support functions in Kosmos. In addition, the Kosmos support for highly precise data exchange between different CAD solutions and industry standard formats offers them a broader market for potential sales. Kubotek Kosmos technologists indicate that their platform has a complete lack of global and static variables in their architecture providing a significant performance benefit in multi-threaded applications. Component libraries are supported, and tested on Windows, MacOS, Linux, and Android operating systems offering the potential for executing on mobile devices. CIMdata welcomes the support for the different operating systems making the platform available to a wider audience.

The Kosmos geometry kernel provides 3D solid models with associative GD&T manufacturing information, surfaces, wireframe, construction geometry, and 2D drawings with GD&T manufacturing information with variable precision. It also supports automatic geometric feature recognition such as machined holes, fillets/rounds and chamfers and includes manifold and non-manifold topology and multi-dimensional bodies.

The Kubotek Kosmos architecture allows customers to license any of the following modules:

- Kosmos Core Modeler

- Complete and universal 3D engineering database

- Modeling

- Boundary representation modeler

- Translation components

- STEP, IGES, VDA, Mesh (STL, OBJ, INP)

- ACIS, Parasolid, JT

- Proprietary native CAD formats

- Graphics

- OpenGL hardware acceleration and memory

- Shading, custom line patterns

Interoperability

The Kubotek Kosmos framework offers a unique interoperability data architecture that minimizes translation by preserving complex geometry structures native to each engineering database that it can import. An innovative variable precision system provides a simple, consistent solution to the problem of data imported from different proprietary CAD databases which use different modeling precision.

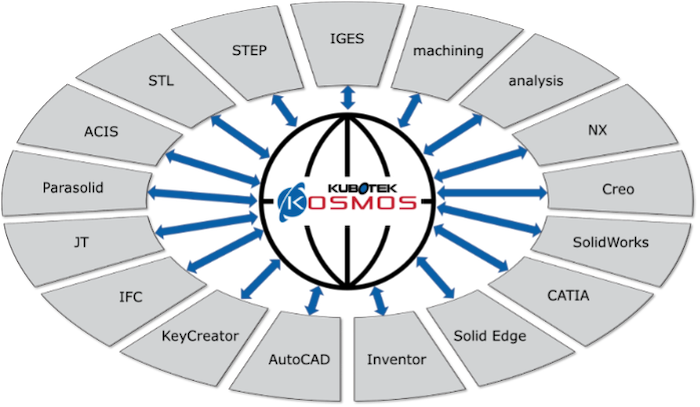

As seen in Figure 2, Kosmos can input standard STEP, IGES and VDA files, neutral ACIS SAT, Parasolid X_T, JT, and STL files, and proprietary files from Dassault CATIA and SolidWorks, Siemens NX and Solid Edge, PTC Creo and Pro/E, and Autodesk Inventor and AutoCAD. CIMdata is impressed with the broad CAD format support that has been delivered.

Figure 2―Kubotek Kosmos support for Data Exchange across Mechanical CAD formats

(Courtesy of Kubotek Kosmos)

Validation and Revision

Kubotek Kosmos has rehosted their impressive data exchange validation and engineering change identification tools on the Kubotek Kosmos platform. Both capabilities, when first released a number of years ago, impressed the CAD industry with their results and speed.

K-Compare Validate offers the complete inspection of data translations and automated compliance reporting ensuring that can evaluate differences as a truly neutral 3rd-party auditor. The tool can open all major CAD file formats without the need of a CAD license. Its pattern matching comparison method provides a complete geometry check and can inform the user if a variance has occurred. CIMdata recognizes that such validation is a requirement in North American aerospace.

The K-Compare Revision tool shows users the differences between two revisions of a product model. It highlights what has been added to the model, what was deleted, and where changes were made. The tool provides an impressive report builder to identify each variation in the model in a multi-page document.

Figure 3―K-Compare Revision Multi-Page Report

(Courtesy of Kubotek Kosmos)

Conclusion

Kubotek Corporation has rebranded their design engineering group as Kubotek Kosmos to refocus on providing an application development platform for special application builders. CIMdata sees this move as opening new business opportunities for the company and a boon to the application development community.

[1] https://www.pcmag.com/encyclopedia/term/component-software

[2] Research for this commentary was partially supported by Kubotek Kosmos.

[3] https://www.datakit.com/en/