Key takeaways:

- Companies in process-oriented industries have many unique challenges to overcome to get products to market and sustain them successfully.

- Rather than the product, the process complexity makes the difference for these companies.

- Tight integration between systems across the product lifecycle is essential to manage the product lifecycle efficiently and realize the benefits in manufacturing (benefits during hand-over, scale-up, and BOM synchronization).

- PLM is a critical enabler for the development of formulated products, and the adoption of an integrated suite such as SAP PLM can help businesses be more efficient.

- Linx-AS has a heritage of success with helping SAP customers developing formula-based products implement PLM and EH&S solutions.

Introduction

Companies in process manufacturing industries have many unique challenges to overcome to get products to market and sustain them successfully―e.g., complex recipe management, performing nutrition and formula analysis, managing artwork, and ensuring labeling accuracy proactively managing product safety and hazardous goods management.

In addition, these businesses must often contend with fragmented IT environments due to the acquisition of other companies and the proliferation of non-standard IT tools.

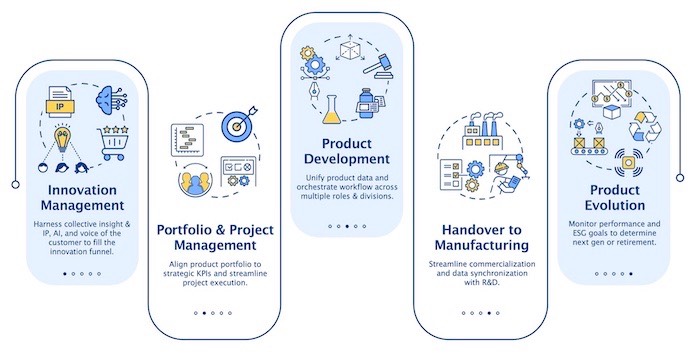

Over the years, many have turned to SAP and their support of process manufacturing businesses to meet their specific needs for IT solutions to help them build an integrated environment as a part of a digital transformation program as shown in Figure 1.

Figure 1―Product Information Flow Within the Process Industry

(Courtesy of Linx-AS)

Digital transformation can be a complex, multi-year project and typically requires the help of an experienced partner. In the case of SAP environments, finding a suitable partner familiar with the sophistication of SAP’s solutions is critical for success.

Integrating Processes Across the Product Lifecycle

Developing innovative products involves supporting each product lifecycle stage: Conceptualize, Develop, Go-To-Market, and Evolve. This requires:

- Focus and optimization of critical high-level processes: Portfolio & Project Management, Product Development, and Commercialization

- Support for many complex detailed process steps involving specialists from many functions using dedicated systems and tools

Tight integration between systems and tools across the product lifecycle is essential to efficiently managing the product lifecycle―but can easily be disrupted by business growth, acquisition, or use of non-standard tools.

In an environment where systems are fragmented, there is a risk of poor communication and lack of management oversight due to users working in information silos, leading to delays and inefficiencies. Fragmented systems can also contribute to inconsistent and redundant product data, preventing companies from achieving a single source of the truth.

A focus on integration can significantly improve the feed of information to Manufacturing where gains in speed to market, agility (reformulation/custom formulation), etc., can be achieved.

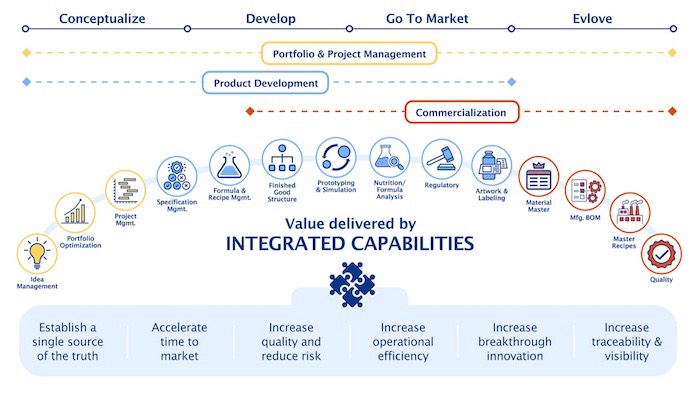

PLM is a Critical Enabler

PLM is a critical enabler for the development of formulated products, and the adoption of an integrated suite such as SAP PLM can help businesses be more efficient. Figure 2 shows the capabilities required to effectively support formulated products and the value the use can deliver.

Figure 2―Process Industry Capabilities and the Value they Deliver

(Courtesy of Linx-AS)

SAP PLM can help business users access and share information and collaborate more effectively by establishing a single source of the truth. This can lead to many benefits:

- Accelerating time to market by eliminating delays between task and process steps and time wasted looking for information or project status

- Raising quality and reducing risk by reducing or eliminating errors and improving information visibility

- Improving operational efficiency by improving communication and collaboration, workflow, and automation of manual processes and tasks

- Increasing the visibility of formula ingredients and traceability throughout the supply chain

These improvements can, in time, lead to more breakthrough innovations, as teams learn to work together more effectively, information flows more efficiently, and management visibility is improved.

Linx-AS History and Growth

Linx-AS is a long-established consulting business focused on helping SAP customers develop formula-based products via implementation of PLM and EH&S solutions. The company is specifically focused on supporting companies in the Consumer Products industry (e.g., Food & Beverage, Personal Care), Life Sciences, and Specialty Chemicals.

Linx-AS was founded 20 years ago by a group of executives from Deloitte’s EH&S practice and has progressively developed its offerings:

- Initial focus on implementation services for SAP’s EH&S solutions

- Added implementation services for SAP’s process manufacturing PLM solutions (Specification Database and DMS)

- Formalized a development group for applications and integration tools

- Diversified service portfolio with SAP User Experience practice

To guide implementations, Linx-AS has developed the Vision Methodology―an accelerated planning process for developing a strategic roadmap for PLM. In CIMdata’s view, methodologies such as this can significantly increase overall project success and benefits.

Linx-AS has also created several solution bundles branded as ROI NowTM and incorporating best practice business processes, SAP solution enhancements, project delivery accelerators, and dedicated support. In CIMdata’s view, delivering pre-configured solution extensions can reduce the time and risk to complete projects and improve overall customer satisfaction.

Linx-AS has also developed expertise in upgrading legacy SAP PLM environments to the latest version of S/4HANA, giving them an edge over system integrators who lack this specific knowledge.

Linx-AS customers include: CPG leaders Edgewell[1] (personal care), Tree House Foods[2] (private label food and beverages), and Blue Diamond[3] (the almond company); biotechnology innovator Stemcell Technologies[4]; and beauty products leader Coty[5].

Conclusions

Companies in process-oriented industries have many unique challenges to overcome to get products to market and sustain them successfully. Tight integration between systems across the product lifecycle is essential to manage the product lifecycle efficiently. PLM is a critical enabler for developing formulated products, and the adoption of an integrated suite such as SAP PLM can help businesses be more efficient.

Linx-AS is a long-established consulting business focused on helping SAP customers develop formula-based products that implement PLM and EH&S solutions.

Overall, CIMdata is impressed by Linx-AS’s focus on SAP, the breadth and completeness of its software and service offerings, and its many impressive reference customers. CIMdata recommends process manufacturing businesses planning to implement or extend SAP’s PLM solutions to consider Linx-AS.

[1] https://edgewell.com

[2] https://www.treehousefoods.com/

[3] https://www.bluediamond.com/

[4] https://www.stemcell.com/

[5] https://www.coty.com/