Key takeaways:

- We are living in a time of great disruption caused by the rapid evolution of technology, socio-economic issues, and geo-political events.

- The lifespan of a successful company is limited by its ability to stay connected to its customers, and rapidly and accurately communicate the value of its products and services.

- A new approach to managing the lifecycle of products called Product Value Management (PVM) offers a way for organizations to continuously and efficiently align their products to market needs.

- Propel has redefined product lifecycle processes for fast-moving companies by focusing on product value and customer engagement.

Introduction and Background

Global markets are being disrupted from multiple directions, making it harder for brand owners to find and communicate the value of their products. Technology is creating opportunities for product evolution at an increasing rate, driven by rapid developments in microelectronics, wireless communications, new materials, and other factors. But technology is not the only thing that is disrupting brand owners and their products:

- Socio-economic issues such as the impact of the global pandemic and inflation are severely impacting economic activity and global supply chains.

- Geo-political events such as the war in Ukraine, tensions with China, and climate change are having unpredictable impacts on global trade.

Despite all of this, one fundamental truth still applies―to be successful, products must engage a segment of the market and improve upon the status quo. Identifying and locking in the value is critical and needs to be clearly and accurately communicated through the lifecycle of the product. It’s the reason customers will buy and hence it creates demand. Driving and managing demand allows businesses to adjust production to the required level and achieve profitability.[1]

Quick and easy access to accurate information and continuous collaboration across cross-functional teams is necessary to maintain this communication. However, many factors must combine to make this value communication work effectively and efficiently, and the process can be easily disrupted leading to sub-optimal market performance.

Propel Software Solutions (Propel) has recently launched its product value management (PVM) platform to help companies create and capture maximum value from product operations. The platform brings product teams (development, quality, production, and supply chain) and commercial teams (marketing/sales and service) together with the promise to expand revenue growth, improve quality, decrease costs, and increase customer satisfaction. According to Propel, while legacy solutions address historical business challenges, its PVM platform enables collaboration across the whole product lifecycle, prioritizing today’s customer and market trends. Propel is focusing its solution on meeting the needs of brand owners of sophisticated products and services.

The Age of Disruption

Change is the norm, and most businesses are adept at dealing with it over short periods of time while maintaining their focus on market needs. However, with more frequent periods of disruption, the situation is very different. Over the last few years, we’ve moved from an era of change into one of great disruption caused by the rapid evolution of technology, socio-economic issues, and geo-political events. For companies to avoid being one of the next to fail, clear steps must be taken. This is apparent for any size company―even the Fortune 500―where 61% of the companies have vanished[2] since 2000.

Technology-Driven Disruption

From cars, to smartphones, to medical devices, or even wireless-connected heated coffee mugs, a huge number of formerly “simple” products have become complex systems, even systems of systems. Products are evolving at an increasing rate, driven by rapid developments in microelectronics, embedded software, wireless communications, cloud computing, new materials, innovative manufacturing processes, and others.

Smartphones have evolved from a simple phone replacement that could also store music to sophisticated devices that enable users to perform a wide range of functions that previously required access to a computer. To achieve this, they’ve integrated many technologies including microelectronics, touch displays, embedded software, digital cameras, wireless communications, and cloud-based services.

Motor vehicles (i.e., cars, trucks, buses, etc.) have been evolving in a number of ways, powered by technological advances. For example: electrification (i.e., replacing the internal combustion engine with electric motors powered by electricity stored in a battery); Advanced Driver Assistance Systems (ADAS) that aim to reduce accidents such as lane departure warning/correction; and self-driving cars―the long predicted, but as yet unachieved, goal of developing a car that can drive itself.

Medical devices have also evolved rapidly over the last several years. They are now performing tasks that were beyond reach until recently, for example complex programmable pacemakers and closed-loop artificial pancreas systems. Advances in microelectronics, embedded software, sensors, and advanced materials continue to make medical devices cheaper and more effective.

Socio-Economic Disruption

While certain advances in technology can be predicted, socio-economic issues usually cannot. In the last three years we have seen the dramatic market disruption caused by a global pandemic. Many areas of economic activity were virtually shut down overnight and, in most cases, remained that way for many months. A huge section of the workforce moved to working from home, dramatically affecting patterns of demand for goods and services. Many global supply chains came to a halt as demand plummeted and/or workforce shortages emerged.

Within the last year we have seen a significant return to “normal” as vaccines allowed people to get back to work, restoring many aspects of supply and demand that existed previously. However, as this was happening, new challenges emerged―inflation and the great resignation which, as of this writing, are still not adequately under control. As prices rise, central banks around the world are responding by raising interest rates in an attempt to dampen inflation. In the meantime, economic activity and global supply chains are again being disrupted.

Geo-Political Disruption

Disruption is also being caused by geo-political events. These are always with us but, like socio-economic issues, are hard to predict. In the last year we’ve witnessed a war in Europe and its resulting political and energy cost instability; tensions with China, which the rest of the world is heavily reliant upon as both a source of production and a growing market in its own right; and the steady advance of climate change.

Any one of these events would have a significant impact on global trade and, hence, demand for goods and services, but simultaneously, they make forecasting demand for goods and services extremely difficult. All of this points to the need to be more agile when it comes to product lifecycle management.

Developing Products & Services That Meet and Exceed Market Needs

To be successful, products and services must engage a segment of the market and “do a job” or “deliver an outcome” that improves on the status quo. This value needs to be clearly identified and communicated to potential customers. Differentiation from competing products may also be required in this expression of value.

Close attention must be paid to the market’s view of the product and how it changes over time, or varies across different market segments. Brand owners need to use this information to refine their products or adjust their production and logistics resources quickly, and in a manner that increases profitability.

At a high level, the process for managing product value through the lifecycle of the product is the responsibility of three groups:

- Developers, who capture market requirements and design new products.

- Makers, who plan and execute the manufacture of the product utilizing internal resources and supply chain partners.

- Sellers, who market the product and sell it either directly or through distribution partners.

The value of a product typically originates with the Developers who, having understood the needs of the market, will design a product to meet those needs. This value needs to be communicated to the Makers and the Sellers. The Makers will ensure that the resulting product adequately meets the Developers’ intent and will deliver value to the market. Sellers are responsible for communicating the value to the market, both through their own marketing and sales channels, as well as those of their partners.

Quick and easy access to accurate information and support for collaboration across cross-functional teams is necessary to maintain this communication, but these goals are not being adequately met by the siloed solutions that currently support most organizations.

Without continuous product collaboration across the business, the flow of information can be negatively impacted in many ways, e.g., the product value may be poorly or incorrectly described, and/or accurate product information may not be available in a timely manner. Both of which can result in errors, confusion, and omission downstream.

This can lead to the following issues:

- Product design is unable to deliver the value expected.

- Manufacturing process does not deliver the product that meets market expectations.

- Manufacturing volumes are not aligned with market demand.

- The market does not see the value of the product.

- The price of the product exceeds its value.

To fully capitalize on the value of a product, information needs to flow in the opposite direction as well. For example:

- Sales volumes and forecasts are needed to adjust manufacturing volumes and distribution patterns.

- Customer feedback, to allow product designs to be optimized.

- Field service information, to allow product issues to be quickly corrected.

- Customer use cases, to deepen brand owners’ understanding of market requirements and find new sources of value.

The same issues that impact the forward movement of product value information (e.g., quality and timeliness) can impact its flow in the reverse direction, leading to an inability or a delay in response to product changes, manufacturing processes, and value messages.

Product Value Management

Sensing the need for a response to market disruption, Propel has redefined product lifecycle processes for fast-moving companies by focusing on product value and customer engagement.

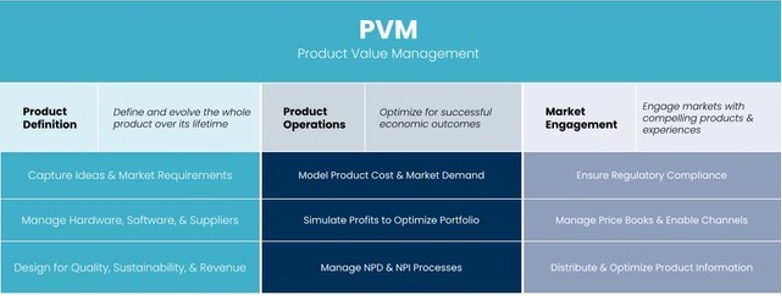

According to Propel, PVM consists of three connected pillars, as defined below and shown in Figure 1:

- Product Definition to capture market needs, define and evolve products over the course of their lifetime, manage supply chains, and design for essential product characteristics such as quality, regulatory, sustainability, and recurring revenue.

- Product Operations to help product and market teams optimize for successful economic outcomes, including deep collaboration between teams to ensure revenue and profitability are integral to product strategy.

- Market Engagement to connect customers with compelling products and experiences, including information needed by sales and marketing teams to commercialize products earlier in the development cycle.

Figure 1―Product Value Management Overview

(Courtesy of Propel)

To achieve the vision of PVM, Propel recently announced its PVM platform designed to help companies create and capture maximum value from product operations. By providing real-time data, cross-functional workflows, and contextual collaboration, Propel’s PVM allows product and commercial teams to work in parallel and speed up traditionally siloed business processes. According to Propel, it is ideal for companies looking to shorten product innovation and go-to-market cycles, create resilient supply chains, and build responsive teams that can quickly adjust to changing customer demands and market conditions.

Select Customer Case Studies

Meyer Sound

Meyer Sound is a global leader in providing integrated solutions for sound reinforcement, spatial sound, acoustic systems, studio monitoring, and high-end residential systems. Its loudspeakers are designed to operate in either a fixed or mobile environment and are often customized according to the needs of the application. The high quality loudspeaker products consist of structural items, electronics, and, in some cases, software. Because of the complexity, multi-disciplinary teams must work together to design products.

During the pandemic when most companies were struggling to pivot business models to survive, Meyer Sound adapted quickly to changing market conditions by focusing on product innovation and geographical market and industry needs. Launching award-winning loudspeaker systems and focusing on installations in performing arts centers, corporate headquarters and universities helped avoid dependence on venues with short-term ticket sales.

According to Meyer Sound’s QA Manager, Mr. Chris Conner, Propel was brought in to replace a legacy PLM solution. The company was looking for improved configurability and process automation. It needed a new solution that could respond quickly, provide flexibility, and increase communication across the business. It needed a single source of truth for all of its documentation, and that source needed to be knowledge based. With an increased work-from-home employee base, it also needed to address existing remote desktop problems, as well as provide worldwide access to teams working from anywhere, including overseas customer sites.

As a leader in the industry, Meyer Sound constantly pushes its product technology to be better, and its internal business technology solutions needed to do the same. According to Mr. Conner, the user experience of Propel compared to its legacy system immediately gained the support of the users with Propel now managing a wide range of product information including parts, BoMs, deviations, change orders, and assembly work instructions. With Propel everything is documented digitally, from manuals to operating guides, to end products, so that technicians can follow a bar code from product to web page, to documentation.

Mr. Conner and his team have implemented workflow automation resulting in significantly improved efficiency and responsiveness. In doing so, it has cut document control overhead by 50%, allowing staff to focus on value-added projects that compress time to market and help expand the company’s award-winning product portfolio.

In conclusion, Mr. Conner said “Propel makes it easy for the engineers to do the work themselves and retain control over the entire process. As an admin I can create solutions for internal systems that weren’t there before, removing the complexity of using a web developer, or an IT department. It’s a huge time saver and the flexibility to configure to our needs gives us full control over who has access to what, and when. Propel gives us a level of complex control without the complexity”.

Blentech

Blentech is a leading manufacturer of professional food processing equipment that operates in a global market but with significant regional variations. According to Blentech’s CEO, Mr. Dan Voit, success requires close attention to customer requirements, a deep knowledge of food science, and innovative engineering.

Mr. Voit and his team were looking for a solution that would act as a “single source of the truth,” making critical product information searchable, easy to find, and reusable. Mr. Voit also had a vision of business-wide collaboration, connecting product development with downstream processes including manufacturing, sales, and customer support. For this reason, he mandated that its new PLM solution run on the Salesforce platform. This led to Blentech selecting Propel.

Not surprisingly, product value management is a concept that resonates with Mr. Voit as he finds that it’s easy to lose sight of almost 70% of vital product information without a single source of truth to work from. His goal is to walk up to a machine, type in the serial number and know everything about it from design to manufacturing, sales and service (and everything in between) so that he can determine the true “value” of the product.

Mr. Voit says Blentech is not just a manufacturer of machines, “it is in the business of providing the capacity to produce safe and nutritious foods.” That may or may not include the sale of new machines, it might be the overhaul of a legacy machine―and to do that well, the company needs to know the full product history and any and all changes made along the way.

Starting with documents, Blentech now stores parts, assemblies, and even software in the Propel solution. The goal, according to Mr. Voit, is to get “everything in there.” Initial results include an increase in design reuse based on standardized sub-assemblies from 10-20% to 50-60%, leading to a significant reduction in costs and design lead-times. In addition, an improvement in quality has resulted in onsite commissioning time being cut by at least 50%.

Next on the list is quality, compliance and CPQ (configure/price/quote). In parallel, Blentech is implementing a new ERP solution, also based on the Salesforce platform―another critical step in realizing its PVM vision.

In summary, Mr. Voit said "Propel’s PVM platform is beyond compelling, it’s fundamentally essential to understand how our design impacts value.”

Propel Background

Propel has a proven track record of delivering solutions that are focused on improving product quality, speeding time to revenue and profit, and improving customer satisfaction. Recognized as a Deloitte Technology Fast 500[3] winner, Propel’s solutions are built on the Salesforce cloud platform and drive product success for hyper growth startups, corporate pioneers, and Fortune 500 leaders in the high-tech, med-tech, and consumer goods industries.

Conclusions

We are living in a time of great disruption caused by the rapid evolution of technology, socio-economic issues, and geo-political events. This is increasing the pressure on brand owners whose success is limited by their ability to stay connected to their customers and communicate the value of their products and services.

Traditional enterprise software solutions do not adequately support the communication of value, due to their siloed nature. But a new approach to managing the lifecycle of products called Product Value Management offers a way for organizations to continuously align their products and services to rapidly changing market needs.

Propel has redefined product lifecycle processes for fast-moving companies by focusing on product value and customer engagement. Their PVM platform helps brand owners create and capture maximum value by bringing product and commercial teams together to expand revenue growth, improve quality, decrease costs, and increase customer satisfaction.

[1] Research for this commentary was partially supported by Propel Software Solutions.

[2] https://www.cimdata.com/en/education/educational-webinars/webinar-cimdata-s-critical-dozen-the-top-12-trends-enablers-for-digital-transformation

[3] https://www.businesswire.com/news/home/20211117005379/en/Propel-Ranked-Number-77-Fastest-Growing-Company-in-North-America-on-the-2021-Deloitte-Technology-Fast-500%E2%84%A2