Key Takeaways

- As automotive products continue to become more complex, OEMs rely more heavily on suppliers with special expertise for sophisticated components and subsystems.

- Managing collaborative interactions, including engineering changes, among the numerous companies that contribute to a vehicle’s definition, manufacture, and support is essential for bottom-line profit.

- The manual data exchange processes that automotive OEMs have used in the past are no longer sufficient given increased business speed, agility, and systems complexity. However, OEM’s that allow suppliers inside their firewall expose themselves to serious risks and liabilities.

- Cooperative and collaborative engineering and manufacturing are evolving throughout the automotive industry requiring trusted exchanges of key information from disparate systems.

- Technology has now advanced to support a collaboration hub independent of the collaboration partners’ internal systems. Companies would do well to review their own interaction with the supply chain and look toward the future by deploying a collaboration hub. Eurostep’s ShareAspace is providing such a hub to innovative automotive OEMs and their key suppliers.

Introduction

Collaboration requires sharing of design data, with confidence and trust. Sharing a controlled configuration as design decisions are made is critical to orchestrating product development across a large company and its suppliers. The degree of collaboration practices changes based on the trust and criticalness of partnership. This can be characterized as degrees of sharing using a color scale from white to grey to black. White collaboration shares everything, all the time. Grey collaboration shares just important details at critical junctions in product development. Black collaboration shares only interface requirements confirmed at build events, from early prototypes to start of mass production.[1]

White sharing of everything happens when there is complete trust in the partnership and most problem solving is done continuously, collaboratively, in near real-time. This is always done when there is a quality issue that is affecting mass production. It requires a close and trusting partnership.

Grey sharing of important details happens when trust exists, but engineering is done independently since key details or parameters have been contractually agreed to and are measured as a design proceeds into mass production. Many automotive OEM and key Tier 1 relationships rely on grey sharing. Sourcing contracts are easier to enforce in these types of controlled sharing, though corrective and preventive action is a slower collaboration impacted by waiting on contractual file exchanges.

Black sharing is typical for raw material and commodity suppliers, even if commodities are complex subsystems, like electronics. The amount of data that needs to be exchanged is much less during development. Often this is driven by a standard―for material content, fastener selected, or mechanical joining interfaces. Trust is not a consideration as the commodity or raw material has an existing experience record in mass production. Black sharing slows problem investigations.

Automotive collaboration is increasingly driven by the following factors:

- Experienced automotive system integrators are helping electric vehicle start-up companies with automotive mass production expertise.

- Legacy OEMs have existing file sharing processes and facilities that are becoming data exchange bottlenecks that rely on both human and older file-based databases.

- Some automotive brands are being sold or acquired by different companies, which then drive the need for sharing engineering files from different solution providers.

Automotive OEMs, electric vehicle startups, and Tier 1’s with mass production experience have data sharing and collaboration demands that are blurring the degree of sharing and stressing existing data file sharing solutions. EV competitiveness makes effective collaboration and data sharing even more vital. The company boundaries in EV competition are very dynamic. Degrees of sharing must remain flexible, even tailorable, while new products are engineered and produced.

Eurostep Eases Engineering & Manufacturing Information Sharing

Eurostep’s services and solutions improve collaboration by enabling the quick exchange of controlled configurations of data―information in a development or manufacturing context. Eurostep’s history with data exchange standards and tools/utilities that enable exchanges and their advisory role to many who create bespoke solutions with all types of customers needing digital engineering and manufacturing tools lead them to realize the need for PLM exchange services. The creation of ShareAspace is the result of their expertise.

CIMdata has written about the requirements for secure, stable data exchanges and the use of state-of-the-art cloud technologies as the basis for the ShareAspace platform. Please read the CIMdata commentaries: ShareAspace: Leveraging Technology Pillars, published 9 September 2021 and A Controlled and Protected Partner and Supplier Collaboration Environment, published on 15 December 2020.

With automotive electrification competitors, Eurostep is positioned to help startups, Tier 1’s, and even legacy OEMs wanting to modernize their collaboration sharing capabilities and their needs for solutions like ShareAspace. Eurostep’s decades long PLM journey started with the development of information exchange standards including STEP AP239, AP242, AP243, and others emphasizing the importance of exchange standards. This experience gave them insights leading to better PLM services, like ShareAspace.

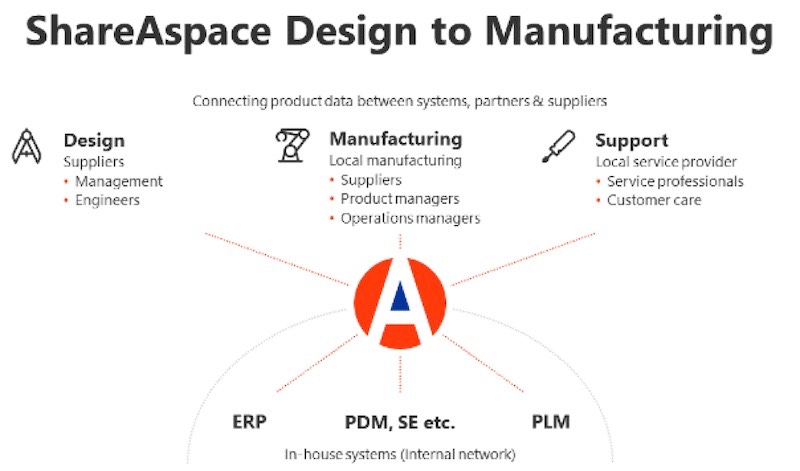

Eurostep’s ShareAspace is a collaboration hub for controlled sharing of product information. Figure 1 depicts the connections between design, manufacturing, and service via ShareAspace even as the data sources are broader than a single PLM solution, which they typically are in large mass production enterprises, especially the automobile industry with its hundreds of suppliers in complex global supply chains.

Figure 1―Data Sharing via ShareAspace

(Courtesy of Eurostep)

The ERP systems needed for global, complex automotive supplier management can be larger than the automotive engineering PLM solutions. Being able to coordinate a set of vehicle information that has pieces from these different PLM and ERP data repositories is key to timely, effective decision making. As countries continue to tighten regulations regarding raw material source and assembly locations, the systems engineering (SE) traceability data for parts and ideas/inventions will present an even more complicated data sharing challenge. Improving information and file exchanges shortens time to key decisions across supply chains. Being able to make decisions in a day instead of weeks or months improves collaboration, understanding, productivity, and product quality.

Many more companies have entered the automotive electrification race, changing boundaries amongst startups, partnerships, consolidations, and Tier 1’s. Tier 1’s and startups are shouldering more innovation and manufacturing responsibilities. The boundaries for exchanges are morphing across the automotive electrification markets as partnerships form, grow, and dissolve. Trusted, secure, and fast information exchanges will be key discriminators in the expanding EV products industries.

Conclusion

File sharing processes, requiring manual steps to share a configured release of engineering or manufacturing data, are slow and error prone. Cloud technologies are enabling innovation partners to quickly share managed information―lots of related data in a decision-making context. Eurostep has built and sells ShareAspace, utilizing Azure cloud services, providing their clients with secure and robust exchanges of related, managed information from key separate data repositories. While many industries are using ShareAspace, the automotive industry is starting to embrace this collaboration solution to improve their competitiveness while developing new electric vehicles.

Eurostep’s PLM leadership has developed and is selling ShareAspace running in Azure subscriptions. Eurostep is ready to help electric vehicle startups, Tier 1’s, and even legacy automotive OEMs wanting to modernize their information sharing collaboration capabilities.

CIMdata recommends that automakers needing secure cloud-based information sharing with their key suppliers and partners consider evaluating ShareAspace from Eurostep. Especially as the auto industry electrifies most of its fleets, effective, fast collaboration of controlled information is crucial. Battery engineering and manufacturing companies who are implementing new battery design and production processes and facilities should include Eurostep’s solutions in their PLM evaluation and selection initiatives