Key Takeaways

- PTC continues to drive and expand their SaaS and cloud delivery strategy with the new “+” product releases, e.g., Creo+ and Windchill+.

- PTC is leveraging Onshape cloud-based system functions in Creo+ to enable multiple users to collaborate on the same product model in real-time–concurrently reviewing, exploring, and editing product designs.

- They have added partnerships with aPriori and Ansys Granta to improve better design for sustainability.

- ServiceMax is the core of PTC’s new Service Lifecycle Management (SLM) solution suite and will manage the physical product of record, extending PTC’s model-based digital thread to encompass the product service lifecycle.

- PTC is tightly integrating Codebeamer and Windchill to deliver more comprehensive requirements management across the full product lifecycle.

CIMdata attended PTC’s LiveWorx 2023, held in Boston May 15 through 18, 2023.[1] Because of the COVID-19 pandemic, this is the first in-person LiveWorx since 2019 and CIMdata was excited to again be able to personally hear and discuss PTC’s many announcements, technologies, and solutions with PTC employees and attendees from around the world.

Mr. James Heppelmann, PTC’s President and CEO, kicked off the event. He highlighted PTC’s themes of “Just in Time” and “Agile” product development and talked about the increasing need for faster product development speed in all industries. He said that “the Future is not something we enter…it is something we create” and stated that PTC is investing in solutions to help its customers create innovative and sustainable products needed to create that future.

Mr. Heppelmann noted that since 2019, PTC has invested over $3 billion in R&D and acquisitions, including 100s of millions of dollars in application lifecycle management (ALM), to create solutions that can enable their customers to achieve more agile and faster product development, production, and service processes. He stated that these investments are playing a “pioneering role” in bringing our industry to the software-as-a-service (SaaS) era. Mr. Heppelmann said that approximately 25% of PTC’s business is delivered by SaaS and reiterated their SaaS “+” strategy (i.e., Windchill+, Creo+, Vuforia+, etc.) is designed to enable dynamic, real-time multi-user collaboration built on PTC’s Atlas technology platform.

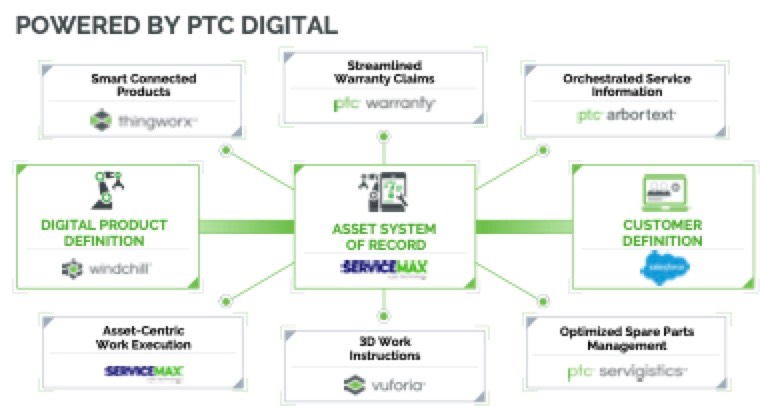

Joining Mr. Heppelmann on stage was Mr. Neil Barua, President SLM Business, PTC to discuss PTC’s ServiceMax acquisition and how it complements and expands PTC’s ability to deliver the physical asset side of a comprehensive lifecycle digital thread. With ServiceMax as the core, PTC has integrated multiple asset service-related solutions in their SLM suite (see Figure 1).

Figure 1―PTC Service Lifecycle Management Suite

(Courtesy of PTC)

PTC is linking this suite and Windchill to create and manage a physical asset-focused system of record. With ServiceMax they are developing an “asset-centric model” in which the as-maintained asset definition serves as the hub.

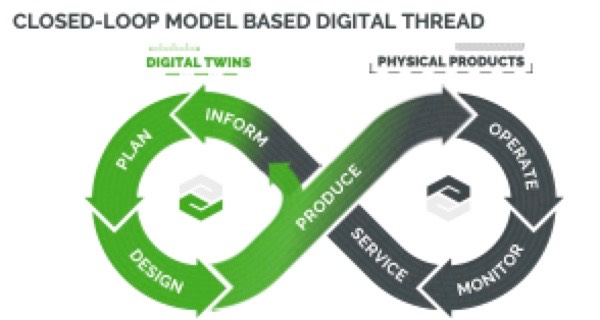

Mr. Heppelmann stated that with their latest solution releases and acquisitions, PTC can now enable its customers to establish a complete model-based digital thread that covers both the digital definitions and twins, as well as in-service physical assets (as shown in Figure 2). He stated that within this digital thread, Windchill will manage the digital product possibilities and ServiceMax will manage the physical product realities.

Figure 2―PTC Model Based Digital Thread

(Courtesy of PTC)

Mr. Heppelmann also described a new environment called the “Industrial Metaverse”―described later in this commentary.

As always, Mr. Heppelmann’s keynote provided insight into PTC’s go-forward strategy, new technology and solution capabilities, and how they are delivering on their commitment to helping their customers be more effective and profitable in today’s and the future’s competitive markets.

Mr. Jon Hirschtick, EVP, Chief Evangelist at PTC, held a “fireside chat” to discuss the need for and evolution to agile development, not just for software but for all aspects of product development. He was joined by Mr. Philip Taber, VP, Engineering from Silverside Detectors, who described how his company was applying agile techniques to hardware development. Mr. Taber said Silverside was using techniques like scrums and Kanban as part of their agile development evolution. He also said that while cloud-native environments weren’t critical, they were tremendously helpful, noting that Silverside significantly increased the frequency and volume of information sharing and that cloud delivery makes it much easier than using an on-premises environment.

Ms. Catherine Kniker, EVP, Chief Strategy Officer, PTC led a session on Design and Manufacture for Sustainability. Ms. Kniker assumed leadership of PTC’s sustainability efforts one year ago. She reiterated PTC’s commitment to sustainability. To support their efforts, PTC has joined the Science-Based Targets initiative with targets of a 50% reduction in carbon footprint by 2030 and a zero footprint by 2050.[2] According to Ms. Kniker, sustainability is not only good for the planet but good for business. Mr. Kniker stated that over 85% of PTC larger customers have made sustainability commitments.

Ms. Kniker said early design decisions impact up to 80% of a product’s sustainability footprint and that PTC will help its customers meet their sustainability goals by providing tools, solutions, and new relationships that will better enable design for sustainability. Two elevated sustainability-related relationships are with Ansys Granta for materials selection and aPriori for determining the cost of manufacturability of components and products. She stated that these two partnerships complement each other, enabling customers to fine tune manufacturability and sustainability early in the design phase. CIMdata is committed to sustainability and eco design and is pleased to see PTC applying its significant resources to helping their customers improve in this critical area.

A very interesting customer-led session, entitled “Cummins–Design for Sustainability While Developing a Design Optimization Culture,” was presented by Mr. David Genter, Director Technology Planning, Cummins. Mr. Genter stated that designing for sustainability makes a company more profitable and enables it to use its engineering resources more effectively. It also changes the mindset designers use to design.

Mr. Genter described the five-step approach Cummins follows to design their products more sustainably:

- Drive Design for Sustainability (DfS) expectations from top-down

- Utilize design optimization subject matter experts (SMEs)

- Update design standards to reflect DfS expectations

- Improve design engineer proficiency

- Roll-out effective tools and training

Among Cummins’ lessons learned was that analysis work must move left―enabling needed optimization to take place earlier. He believes that following a serial design, analysis, design, etc., process cannot support today’s development processes and business needs. Cummins uses PTC’s “pop-up metaverse” capabilities to quickly scan existing equipment for incorporation into a virtual product usage scenario. By quick, it was a matter of minutes, important in use cases where time is of the essence. CIMdata thinks that the Cummins example provides practical insight into more effective ways to implement design for sustainability.

One of the most popular LiveWorx sessions is the Influencer Q&A with Mr. Heppelmann―joined this year by Mr. Barua and Mr. Steve Dertien, CTO, PTC. Mr. Heppelmann helped the audience understand the positioning of the Creo/Windchill suite versus the Onshape/Arena suite of solutions. He stated that the Onshape/Arena suite is primarily designed for companies that need to “go fast,” in which speed of product development is paramount, e.g., consumer electronics. The Creo/Windchill suite is designed to support companies developing more complex products (i.e., automobiles, heavy machinery, etc.) in which component reuse and company efficiency are more critical.

Other topics of note included:

- Atlas is PTC’s go-forward global platform strategy.

- Users can do full generative design in Onshape.

- PTC plans to use generative artificial intelligence (AI) technology within all their solutions–every product is a candidate for chatbots, etc. Mr. Heppelmann said PTC will put generative 3D in the free version of Onshape to better raise the tide of understanding of it.

- They have developed integrations between Creo and Windchill, and Rockwell Automations’ Emulate3D solution for factory digital twins to support virtual commissioning.

CIMdata thought that the Influencer session provided many useful insights as to PTC’s go-forward strategy and product direction.

Now back to the Industrial Metaverse introduced by Mr. Heppelmann in his keynote address. Mr. Dertien, Mr. Valentin Heun, VP Innovation Engineering, PTC, Ms. Shiva Kashalkar, VP Product Management PTC, and Mr. Helmut Draxler, CDIO, Burckhardt Compression Group, led a focused session on the topic. The objective of the Industrial Metaverse is to create a blending of the digital and physical worlds to solve spatial problems in engineering, manufacturing, and field service operations. It integrates:

- Rapid, spatial digital twin

- Spatial real-time-collaboration

- Easy access to digital thread

- Motion analytics

The intent is to create a “digital shadow” and track changes to an as-maintained asset as it is used in service. PTC described three use cases for such a “shadow:”

- Field service–a pop-up metaverse enabling remote assistance for mission-critical repair; teleporting remote experts to the site of the asset.

- Manufacturing operations–ergonomics.

- Design & engineering.

CIMdata found the concept of an Industrial Metaverse very interesting. In some respects, the PLM market has been laying the foundation for the Industrial Metaverse for several decades. Technologies like design visualization and virtual/digital have been around since the 1990s. PTC’s CAD technology and expertise and their Vuforia acquisition have PTC well positioned to respond to this trend. We look forward to seeing how PTC brings it to fruition.

With all of their product lines having or soon getting a “+”, Mr. Brian Thompson, Divisional VP & General Manager of PTC’s CAD Segment, presented “Where Creo and Creo+ Meet: A Roadmap.” During his presentation he announced the release of the Creo+ SaaS CAD solution, as well as the 10th version of PTC’s Creo CAD software. Mr. Thompson emphasized that both are built on the same code base and that all capabilities in Creo 10 are included within Creo+. While still an on-premises product, Creo+ combines the capabilities of Creo with selected cloud-based tools to enhance design collaboration and simplify CAD administration.

PTC leverages some of their Onshape cloud-based system functions to enable multiple users to collaborate on the same product model in real-time―concurrently reviewing, exploring, and editing product designs. PTC added Onshape’s branching capabilities to Creo+ to allow users to explore alternate design variations and, if deemed appropriate, merge these exploration branches back into the main design. CIMdata sees this as a major step forward in collaboration for Creo+ users.

Creo+ also includes the PTC Control Center application, powered by the PTC Atlas SaaS platform, which is designed to provide easy deployment and management of software licenses for cloud-based tools.

Mr. Hedley Apperly, VP Product Management and Strategy-SSE, PTC and Mr. Jeff Zemsky, VP Product Management, PTC, led a session entitled “The Value of ALM-PLM Integration for Digital Product Traceability.” During this session Mr. Apperly and Mr. Zemsky presented PTC’s integrated development roadmaps for Codebeamer and Windchill. They discussed the importance of comprehensive requirements management (RM) and traceability, as well as why it is essential for systems engineering. They noted that RM is most effective when seamlessly integrated within a PLM environment. Codebeamer enables comprehensive RM across many segments of a product’s lifecycle. By combining their RM and PLM capabilities into an environment of cooperating solutions, PTC is addressing one of the most important PLM challenges. CIMdata looks forward to seeing the joint capabilities the integrated RM solution will be able to deliver. PTC’s legacy requirements solution, formerly known as MKS Integrity, has been rebranded Requirements, Validation & Software (RV&S) and PTC stated they will continue to support that product for existing customers.

Concluding Remarks

LiveWorx is always an exciting event presenting PTC’s solutions and commitment to helping their customers create, deliver, and service todays and tomorrow’s increasingly complex smart connected products. LiveWorx showcased the full range of PTC solutions and partnerships. Sessions covered all of PTC’s products and technologies and demonstrated PTC’s broad suite of solutions to better address the end-to-end product lifecycle, support faster, agile product development, and deliver higher business value to their customers and their customers’ customers. CIMdata believes that the new solutions, updates of current solutions, and new and expanded strategic partnerships will enable PTC to maintain its position as a leading provider of CAD, PLM, ALM, and SLM solutions.

[1] Travel and/or other expenses related to this commentary were provided by PTC.

[2] Science-Based Targets is a global partnership founded to help show companies and financial institutions how much and how quickly they need to reduce their greenhouse gas (GHG) emissions to prevent the worst effects of climate change. https://sciencebasedtargets.org/