From concept to ship design through operations and maintenance.

Key takeaways

- Maritime lifecycles are complex and long. Eurostep has developed solutions that help maritime companies support the maritime lifecycle from conceptual design, construction, and throughout the operational maintenance of their ships and maritime products (e.g., oil rigs, etc.)―by gathering and linking the information that creates and supports the digital thread.

- An important aspect of maritime lifecycle support is to develop and track the up-to-date configurations of individual ships, classes of ships and their systems and subsystems throughout their life, regardless of where they are at any time globally.

- Changes to ships and other marine vessels are made anytime, anywhere, so tracking their maintenance lifecycles is very difficult. Eurostep has developed specific capabilities to support activities required to enable global maritime lifecycles and Marine 4.0.

- Throughout the lifecycle, supplier collaboration support is critical and must be secured.

- ShareAspace from Eurostep provides a solution to the above challenges. It helps companies move away from documents and toward digital processes to support Maritime 4.0. Thus, ShareAspace is an enabler for any organization transforming its business to digital.

Introduction

The maritime industry is characterized by a number of complex issues that inform all aspects of conceiving, designing, building, delivering, maintaining, upgrading, and financing maritime projects such as ships, offshore vessels, undersea installations, and others.[1] Some of these that particularly impact on how shipbuilders operate and move to a more digitalized business include:

- Product and construction complexity and size―ships and other maritime structures contain many mechanical, electrical/electronics, and software systems. Safety and architectural issues include space layout, routed systems such as HVAC, human support systems, etc., as well as planning for build activities of very large-scale structures that are undertaken, often in cramped facilities. Shipyard manufacturing operation planning must address a high level of complexity. Plans for moving large structures throughout a shipyard are complicated by crane lifting capacity, where very large sections of ships and other maritime systems can be fabricated and stored before assembly, sequencing of assembly operations, maintaining operational systems (such as generators) during long build cycles, and many other issues.

- Marine construction companies operate in a complex, collaborative business environment in which multiple organizations design a ship and its components, the shipbuilder constructs it, other companies maintain it, it is financed by another institution, and the owner/operator approves it for use. Thus, marine building projects often take years to complete. The long timelines demand effective project management. They also increase the likelihood that technologies, customer requirements, and regulatory practices will change before the ship or vessel is commissioned.

- There is a large variation in the types of maritime projects that are undertaken, each requiring specialized expertise and applied technology. The variation ranges across surface and submersible vessels, manned and un-manned, small workboats to large ocean vessels, floating and fixed rigs, military and civilian.

- Ships are often designed to be built as a class structure wherein all of the ships in a class are similar but are almost never identical. This creates a configuration management situation for which most shipbuilders are ill prepared. For vessels that can have millions of parts, maintaining the configuration of each vessel becomes a difficult task and requires comprehensive configuration management capabilities. In addition, ships in-service undergo continuous change. The as-designed, as-built, and as-maintained configurations, when maintained properly, become the digital twin that enable manufacturing, maintenance, and operation to be managed much more efficiently.

- Design/build/construction/maintenance complexity―coordination of materials, system and subsystem acquisition, coordinated management and collaboration of suppliers across many disciplines, comprehensive project management including procurement, worker management, construction and assembly processes, handover, and maintenance. This results in a complex environment for defining, acquiring, collaborating on, and managing the digital models and data required to design, construct, test, commission, and maintain maritime vessels and equipment.

- Supply chain complexity―many suppliers in different disciplines use heterogeneous technology solutions (such as multi-CAD), spread internationally, with communication issues and difficult delivery schedules.

- The regulatory environment for shipbuilders is complex and continuously evolving. There are a multitude of international and national rules and standards that must be adhered to. These include safety, environmental, material, labor, and other regulations.

- Ships are typically not stationary. They operate globally in harsh environments and need to be supported globally. Therefore, information on each ship’s configuration (its digital twin) needs to be captured and maintained. This is a daunting task to execute manually.

- IP protection and data security are particularly critical in military shipbuilding but are also important for maintaining the integrity of information provided by owner/operators and suppliers of various equipment used on board of ships and vessels.

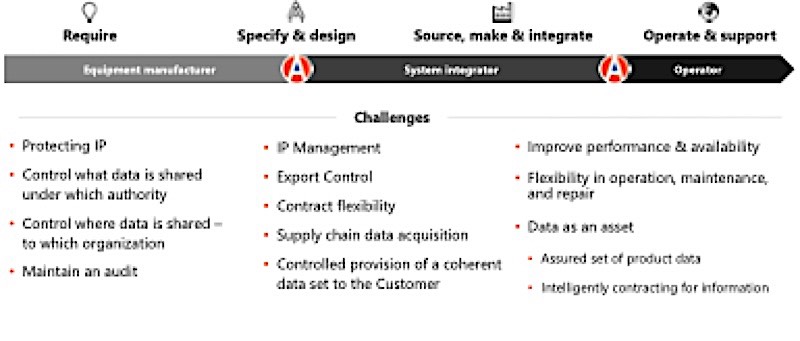

Supporting Maritime 4.0[2] raises many digitalization challenges. Some of these are shown in Figure 1.

Figure 1―Industry Challenges

(Courtesy of Eurostep)

Many of these challenges are discussed above. Others are mitigated by introducing digitalization concepts such as digital twins and digital threads that span the ship or maritime systems end-to-end lifecycle. Eurostep ShareAspace provides many aspects required to support the collaborative digital twin, digital thread, and digital ship or maritime systems that make up the backbone of a Maritime 4.0 strategy solution.

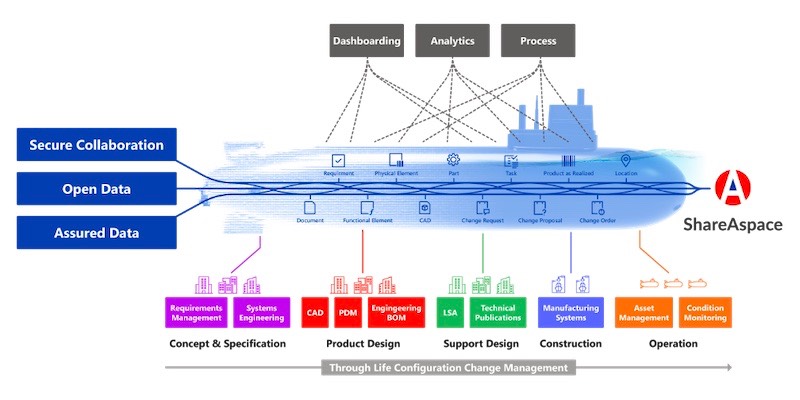

Eurostep’s Solution Suite

As can be seen in Figure2, ShareAspace, Eurostep’s flagship product framework, supports the multiple processes and application domains required to enable a Maritime 4.0 strategy that integrates the activities required by owner/operators, prime maritime systems builders, and suppliers. It acts as a collaboration hub for activities and data that have to be coordinated among the various participants in the shipbuilding community.

Shipbuilders can use ShareAspace to integrate disparate CAD solutions and other product development applications (e.g., simulation and analysis) to create a single source of shareable ship and maritime systems design information. This includes creating and sharing configurations in the form of complex Bill of Materials (BOMs) that include items from multiple disciplines (e.g., mechanical, electrical, electronics, software, and others) supporting individual vessels and ship classes, including baselines for sub-classes and other variations.

Figure 2―ShareAspace’s Process Coverage for Maritime 4.0

(Courtesy of Eurostep)

The data sets in ShareAspace can be managed in variations throughout the life of classes and individual configurations. This is critical since changes that are being considered may be applicable to a whole class of ships or maritime systems, a sub-class, or an individual system. Being able to search for variations in items, as well as the use of the same item across several ships or a class, is critical to facilitating correct and complete understanding of the impact of changes being considered. This is a very difficult, if not impossible task, in a manual environment or one in which the relationships between a class and the variations of the class members (individual ships) are not structured and managed. In addition, changes to a ship’s or maritime system’s design aspects have to be carefully managed throughout the lifecycle. To do this, the data has to be known and people have to be able to find it, which implies a comprehensive data management environment across design, construction, and operations. A third aspect of through-life support is to support analysis of data in the context of, first, the as-built system, then in the context of the as-maintained and as-serviced system―that is, what has changed, how, and why. ShareAspace supports a comprehensive integrated data environment that allows shipbuilders and operators to deal with the complex and abundant information that makes up the historical and projected configuration of ships and maritime systems in operation.

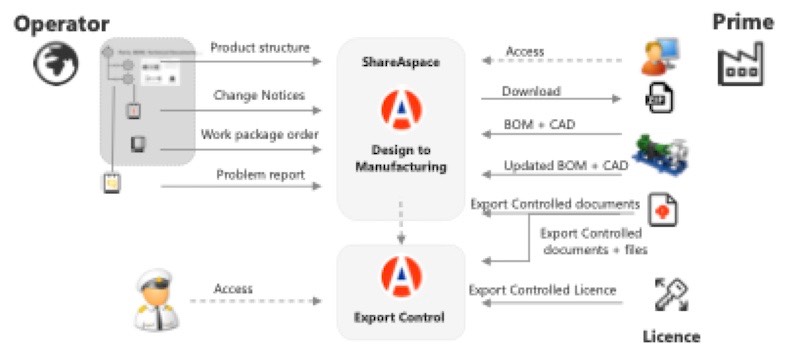

As mentioned earlier, the relationship between a shipbuilder and its multitude of suppliers is complex. Too often, this relationship is adversarial in some ways, with suppliers not wanting to share their IP with the shipbuilders and vice-versa. IP protection extends to the relationships between various suppliers, where competitive relationships can be even more difficult―wherein for one area two suppliers may be competitors and for another area they may be partners. Design information flow has to be managed to allow bidding and other activities to be expedited. After bid, the contracts and any issues need to be managed to support quality approvals and delivery needs.

Collaboration among all of the, often intertwined, players is paramount to creating more innovative and cost-effective maritime solutions. The collaborations that need to be supported are further aggravated by the fact that not all suppliers need the same types of information. The data required varies by type of supplier-shipbuilder relationship, from equipment suppliers who need simple data on the item to be purchased, to suppliers who build to a specific shipbuilder need, to co-design suppliers who interact with the shipbuilder to co-develop a specialized piece of equipment. ShareAspace provides a platform in which secured collaboration is a built-in capability. It has been demonstrated to be appropriate in commercial as well more restrictive naval environments (leveraging ShareAspace Export Control).

In-service asset management is another major issue in the maritime industry. Ships are rarely stationary. They tend to be repaired while in operation or in far-flung locations that may be anywhere in the world. The huge issue for owner/operators and maintenance organizations is capturing and keeping the in-service configuration of the vessel up-to-date. ShareAspace enables an as-maintained system of record that provides a secure and organized place to store configuration information as it changes. This helps alleviate the physical audits and scanning that often have to be done when a ship arrives at a maintenance facility. This can save weeks, even months, of work before the actual maintenance can commence.

Supporting a digital twin of each ship or maritime systems provides a basis for a lifecycle digital thread that spans all aspects of each system’s lifecycle. The digital thread connects all elements of a system’s complex data as well as the data’s lifecycle as the ship or maritime systems moves from design to build to operation. This aspect of ShareAspace supports full lifecycle configuration management as illustrated in Figure 3. This allows organizations to track changes for individual vessels and across classes. The digital twins are based on using structured data and information rather than documents that have to be parsed to determine their contents. However, document contents can be indexed to facilitate searching.

Figure 3―Extended Digital Thread and Digital Ship

Courtesy of Eurostep)

Interoperability

To facilitate Maritime 4.0 shipbuilders and other maritime industry companies need to digitalize their enterprises. Doing so provides the foundation and platform upon which these enterprises can position themselves to resolve the issues raised above and provide their customers with superior maritime solutions. A key element of a digitalized product development platform is to be able to support data from and integrate with the multitude of solutions used to design products in the maritime industry today. Interoperability is not an optional concept. It is a central capability of a viable solution that is capable of spanning the full maritime lifecycle from concept through life.

ShareAspace provides methods (via a REST API and messaging system) to create integrations and Interoperability with shipbuilding tools from other solution suppliers as well as with enterprise applications such as product data management (PDM), enterprise resource planning (ERP), design software (MCAD, ECAD, plant design), software development, manufacturing planning and computer-aided manufacturing (CAM), operations support, and others. Equally important is that ShareAspace’s collaboration environment supports integrations across business process, both within an organization and with its suppliers.

User Observations

BAE Systems is a large, international provider of products and services supplied to various military and civilian customers. One of the company’s primary objectives is to help its customers navigate the difficulties inherent in digital asset management across their products’ lifecycles. BAE enables organizations to deliver Engineering through life support (ETLS) by delivering value across the digital thread. The aim is to capture and manage data to support assets (e.g., ships, aircraft, ground vehicles) from concept through to decommission. This exposes BAE Systems to all the issues faced by a prime contractor when working in a complex supply chain of varied suppliers, owners/operators, maintainers, and logistics. To overcome these issues, BAE Systems uses ShareAspace as a data aggregator, collaboration hub, and process control tool.

Mr. Luigi Sidoli, Head of Campaigns and Programmes at BAE Systems Digital Intelligence, stated that a primary reason for its adoption of ShareAspace was its “ability to aggregate configurations and provide essential ETLS for complex assets.” The company has created an asset breakdown structure in ShareAspace that enables organizations to capture and analyze the actions required to maintain an asset’s operational readiness and upgrade schedule. Supporting the logistics of supply chains and maintenance facilities viewed by BAE Systems as a key part of lifecycle asset management.

Mr. Sidoli also reiterated three critical aspects of asset management: improving asset availability, enhancing efficiencies, and reducing cost of ownership. BAE Systems utilizes ShareAspace’s inherent adoption of the ASD and STEP standards to meet their customer’s requirements in an integrated, collaborative environment. He noted that many customers had never previously used a central environment to support their supply chain, and that it helps competitive suppliers share and work together without compromising their IP through a COTS solution suite.

Benefits cited by BAE Systems include:

- Working with a small to medium enterprise (e.g., Eurostep) is an important aspect of its business operations

- Availability of a tried and tested COTS solution

- Ability to support its customers with best-of-breed solutions

- Access to Eurostep’s expertise of ingesting, managing, and reusing data; and capabilities honed by experiences from other industries

Conclusion

The Eurostep ShareAspace offers maritime operators and others access to design, build, and operational maintenance planning and execution data, work processes, and tools to help support complex maritime industry requirements including configuration of ship classes and individual ships and supplier collaboration through life. Eurostep’s ShareAspace strategy provides benefits to maritime industry clients across domains. ShareAspace’s integrated data and process management helps everyone involved in a maritime program make more informed decisions more rapidly. These can impact design, engineering, analysis, procurement, manufacturing planning, service, logistics, and other activities.

ShareAspace helps shipbuilders and other organizations achieve a digitalized environment that advances Marine 4.0. It can help improve performance by streamlining processes, reduce errors throughout a ships or maritime systems lifecycle, result in cost savings, and more satisfied customers.

CIMdata recommends that companies acquiring or updating maritime lifecycle management solutions include ShareAspace in their evaluation.

[1] Research for this commentary was partially supported by Eurostep.

[2] See: https://www.sciencedirect.com/science/article/pii/S2351978920306430