Existing clients & new prospects―value for everyone

Key Takeaways

- Hexagon launches Nexus for Developers, enabling manufacturers to build innovative digital reality solutions for engineering and manufacturing.

- Hexagon will connect their HxDR reality capture and Nexus Manufacturing platforms with NVIDIA Omniverse, a platform for developing and operating industrial metaverse applications.

- Hexagon Manufacturing Intelligence launched a new automated robotic inspection solution, PRESTO, which enables manufacturers to reduce inspection time.

- Hexagon’s HxDR powers Reality Cloud Studio―ushering automated Digital Reality to the cloud.

CIMdata attended Hexagon’s HxGN LIVE Global 2023, held in Las Vegas, Nevada, June 12 through 15, 2023.[1] CIMdata was excited to hear and discuss Hexagon’s many announcements, technologies, and solutions with key Hexagon personnel and some of the over 3,600 attendees who came from 37 countries.

Mr. Paolo Guglielmini, Hexagon’s President and CEO, opened the event with a powerful keynote titled “Optimism at scale,” which focused on the power of you, technology, and community. Mr. Guglielmini introduced the equation, “You + Community + Technology,” explaining that change happens with the vision of a few who collaborate with like-minded people in a community and use technology to scale. This formula encourages connectedness and openness while scaling optimism in our personal responsibility, passion, growth, and human-centric technology innovation.

Mr. Guglielmini introduced five visionaries to demonstrate what optimism using Hexagon technology looks like. Mr. Guglielmini first interviewed Mr. Lukas Czinger, the co-founder and COO of Divergent, a recent partner of Hexagon. Divergent is a Tier One automotive and aerospace manufacturer who reimagined how to produce complex automotive and aerospace structures to drive digital production. They use software and hardware that is product-agnostic to sustainably manufacture multiple complex structures back-to-back with no downtime.

Mr. Albert Becker, Head of CAE & BIM Support at Bayer AG, then described how Hexagon enabled their digitalization journey with the use of digital twins to transform its operations by improving their data analytics and reducing waste. Mr. Guglielmini then interviewed Mr. Ben Macnamara, CEO of CBH Group, Australia’s largest co-operative and a leader in the grain industry. Mr. Macnamara described how Hexagon’s technology enabled them to automate haulage, an innovation that resulted in less waste and greater profits.

Mr. Nick Pfenning, Senior Superintendent at Mortenson, a major U.S. construction company, shared the benefits of digital construction and green AEC. He described how they designed and constructed modular guest rooms for a hotel using reality capture, drone flights, photo documentation, and autonomous robotics in the placement of guest rooms at the construction site.

Lastly, Mr. Erik Josefsson, CEO of R-evolution, Hexagon’s sustainable innovation and green-tech investment subsidiary, shared how they capture carbon with seagrass conservation in the Bahamas, capturing thirty-five times as much carbon as forests. Mr. Josefsson shared a video by the country’s Prime Minister, Philip “Brave” Davis, who explained the importance of the ocean’s largest natural carbon sink, which awards blue carbon credits. R-evolution has active sustainability and decarbonization projects including solar, wind, and green hydrogen.

Furthermore, Mr. Guglielmini discussed how both personal and corporate vision can lead to a better world. Mr. Guglielmini went on to say that decarbonizing our planet and reducing CO2 emissions in line with the 1.5C target, as outlined by the United Nations, is an optimistic vision that can be achieved with holistic solutions for the prosperity of people, industry, and our planet. CIMdata was encouraged to see Hexagon’s commitment to decarbonization and a sustainable circular economy, which will benefit many of their customers. Mr. Guglielmini concluded by discussing “optimism” and that it is really about action, looking at challenges and finding solutions, and positively impacting the world. Mr. Guglielmini stated the mission the Hexagon community and Hexagon itself are on is essentially the same. Growing a business sustainably requires innovative solutions. He urged this community to reach out with their requirements and challenges, and his commitment to them was that Hexagon would be there to help them do better and be better.

The following day, Hexagon’s CTO, Mr. Burkhard Boeckem, hosted HxGN LIVE Global’s first innovation day with his presentation titled, “Right here. Right now.” Building on Mr. Guglielmini’s presentation, “Optimism at scale,” Mr. Boeckem discussed three themes: human-centric design, connecting everyone, and access to everywhere from anywhere.

Hexagon’s human-centric design could be seen in multiple Hexagon products discussed, including Leica BLK360, their 3D scanning solution; CAS310, a hardware and software mining collision solution; Leica AP20 AutoPole, a surveying tool for creating survey points; PRESTO, an automated meteorology test inspection solution designed for non-robotic experts; and Leica Pegasus TRK Series, a set of mobile mapping solutions used by GIS professionals to collect data and capture asset information autonomously. Hexagon redesigned major parts of their product line to simplify the user experience.

Connecting everyone focused on Nexus―the open digital reality platform for manufacturers. Mr. Andy Pratt, VP of Customer Innovation, joined Mr. Boeckem virtually to speak about Nexus and the continued collaboration between Hexagon and Microsoft. Mr. Boeckem introduced Reality Cloud Studio, a new application on Hexagon’s HxDR platform that combines cloud-based storage, visualization, and a collaboration space to visualize, mesh, register, and store data. This enables users to upload and register scans automatically using Leica BLK solutions. Mr. Boeckem’s session highlighted the power of innovation, prioritizing the needs of the user with human-centric innovation. He focused on new partnerships and groundbreaking innovations.

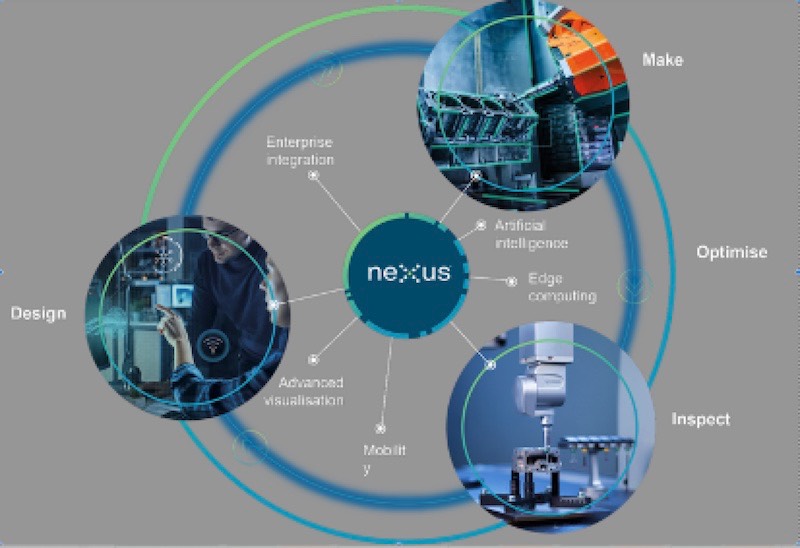

During the event, Hexagon’s Manufacturing Intelligence division announced Nexus for Developers, a dedicated development environment that anyone can use to build native SaaS applications and connected solutions for engineering and manufacturing. This open digital reality platform provides a framework via their Software Development solution that connects Hexagon and third-party engineering, manufacturing, and quality assurance products and solutions. Once an application is plugged into the Nexus platform, it maintains connectivity and allows users to synchronize disparate tools between cloud, enterprise, and desktop applications for real-time collaboration. The new tool set allows professional developers to rapidly develop new unique services from libraries, which offer reusable user interface components that enable them to develop high-quality, feature-rich user experiences. Hexagon’s goal is to develop an ecosystem of technology providers connecting their third-party applications to the Nexus platform, with Hexagon products to deliver powerful manufacturing solutions for customers.

The Nexus Platform

(Courtesy of Hexagon)

Altium is the first company to connect its cloud platform to the Nexus platform, integrating thermal simulation capabilities delivered by Hexagon’s computational fluid dynamics (CFD) software with printed circuit board (PCB) design tools via its Altium 365 platform. Altium users now have access to Hexagon engineering and manufacturing data, speeding up product development and reducing waste. CIMdata is impressed with the Nexus platform and its ability to connect the manufacturing ecosystem, from Hexagon’s powerful (formerly MSC Software) simulation and analysis suite, through their Computer Aided Manufacturing (CAM) and metrology offerings, to an offering built on their powerful HxDR reality capture platform.

Hexagon will connect its HxDR reality capture platform and Nexus platform for manufacturing with NVIDIA’s Omniverse, a platform for developing and operating industrial metaverse applications. This will enable multi-user workflows through a unified view of factory planning and design, as well as optimization in quality and operations. This integration will be based on the Universal Scene Description (USD) framework. The connected platforms will provide complementary technologies that enable customers to advance manufacturing for smart factories and accelerate the power of digital twins for manufacturing, construction, intelligent cities, and infrastructure. The next frontier is robotics, and the shared vision of Hexagon and NVIDIA is to train robots in virtual worlds and enable autonomy for everything that moves. CIMdata is very excited to see the outcome of this powerful partnership.

Hexagon’s Manufacturing Intelligence division launched its new automated robotic inspection cell, PRESTO, which enables manufacturers to reduce quality inspection time and increase efficiency. The solution builds on Hexagon’s leading HxGN Robotic Automation software that integrates Hexagon’s state-of-the-art 3D scanning and absolute positioning technologies and software in a single turn-key solution. With PRESTO, Hexagon is adapting quality inspection to enable the future of smaller-batch production of larger volume parts. CIMdata is impressed with PRESTO’s ability to connect inspection to the rest of the manufacturing ecosystem, with its unparalleled flexibility. We see this turnkey solution as adding increased flexibility, and being easy to use, not requiring a robotics expert to run.

Concluding Remarks

Hexagon’s HxGN Live Conference showcased a wide variety of their digital reality and automated solutions across industrial, manufacturing, infrastructure, and the public sector. Hexagon’s solutions and ecosystems are becoming more connected and autonomous, ensuring scalable and sustainable outcomes for their customers.

CIMdata is impressed with the breadth of Hexagon’s offerings that enable digitalization at scale, including Hexagon’s HxDR platform, and the connectivity and openness of their Nexus platform. CIMdata believes that Hexagon’s direction, strategic partnerships, new solutions, and significant updates of current solutions will enable it to maintain its position as a leading provider of digitalization and automated solutions and capabilities for customers across the many industries they serve.

[1] Travel and/or other expenses related to this commentary were provided by Hexagon AB.