Managing relevant product lifecycle aspects of sustainability

Key Takeaways

- Companies are struggling to define, measure, and meet their sustainability goals. The Aras platform provides the ability to reduce sustainability challenges, enabling flexible transformation to meet business objectives and the needs of a circular economy.

- The Aras platform can help companies manage the processes for reducing their product carbon footprint from raw material extraction, design, manufacturing, transport, and through end-of-life to meet the needs of a circular economy and UN Sustainability Goals both now and in the future.

- The Aras platform enables companies to transform from document-centric to data-driven product information, as well as manage all types of sustainability data (e.g., CO2, substance, material, regulatory), which will continue to evolve in the future across the product lifecycle, in an expanding circular economy.

- Designing for sustainability cannot take place without intensive collaboration with the product lifecycle value chain. Aras provides significant capabilities to collaborate with suppliers through end-of-life.

Introduction

The earth is warming―currently 1.2°C warmer than the preindustrial period―and is steadily increasing.[1] We continue to pump carbon dioxide and other greenhouse gases (GHGs) into the atmosphere. In 2013, CO2 levels surpassed 400 parts per million (ppm) for the first time in recorded history. Today, we are at 418.51 ppm.[2] These gases are trapping the sun’s energy in the earth’s systems, causing global warming and other long-term planetary impacts. The heating of our atmosphere, ocean, and land is causing widespread human-induced climate change.[3] To keep global warming below 2°C, preferably to no more than 1.5°C―as called for in the Paris Agreement―emissions need to be reduced by 45% by 2030 and reach net zero by 2050.[4] Global warming and the climate change it causes are motivating people to act. They are also acting on a wide variety of related sustainability issues such as waste, biodiversity loss, water scarcity, and others that are products of the “take, make, waste” linear economy that must transform to a more circular model. A circular economy is based on a model of production and consumption that seeks to re-use resources more sustainably. Unfortunately, there is a huge gap between ambition and action.[5]

Business Issues

While demands for corporate sustainability and net-zero emissions now come from a growing number and wide range of stakeholders (i.e., investors, customers, supply chain partners, government agencies, and employees), companies are struggling with how to define, measure, and meet their sustainability goals while maintaining their business growth and profitability.

As climate change and sustainability issues worsen, policymakers are passing both incentives and regulations. One of the most important regulations is the European Union’s (EU) pledge to make sustainable products and circular business models the norm in the EU. As part of the Eco-design for Sustainable Product Passport (ESPR), the EU has introduced a Digital Product Passport (DPP) for a wide range of products, mandating the tracking of pertinent sustainability data throughout a product’s lifecycle.

The lack of progress is not because investors and CEOs are unwilling to make the necessary investments. Last year, investors poured a record $649 billion into Environmental, Social, and Governance (ESG) related funds, compared to $285 billion in 2019, which accounts for 10% of worldwide investments in 2021.[6] CIMdata’s view is that many companies are struggling to capture and leverage the knowledge of how to transform into sustainable companies.

Less than two-thirds of directors say their board understands the company’s climate risk/strategy or the internal processes and controls around data collection―with just more than half believing they understand the company’s carbon emissions.[7] Companies typically lack the key product indicators (KPIs) to track progress on their sustainability initiatives. [8]Based on CIMdata’s own research, there is a disconnect between companies’ goals, middle management understanding, and execution. Most organizations lack the culture or mindset necessary to transform into one that embraces sustainability. Few have formal training on sustainability. Many do not know how to reduce their organization’s carbon footprint or their product carbon footprint (PCF). Most companies lack the ability to design their products for sustainability.[9]

Few companies (industrial or software solution providers) understood just how bad global warming and climate change would become less than a decade ago or that they’d be undertaking one of the largest and most important transformations in our lifetime and for generations to come. In addition to the people and process challenges, current enterprise and PLM data models have not traditionally supported sustainability. They have lacked sustainability-related items, sustainability-related material characteristics, and the associated attributes and processes across the product lifecycle. Compounding this, a wide range of regulations (i.e., sustainability, waste & environment, material substance, and ESG) are quickly evolving.

CIMdata believes PLM platforms can provide a flexible way to transform to meet the needs of companies trying to achieve their sustainability goals and play a crucial role in the growing circular economy.

Sustainability Management with the Aras Platform

The Aras platform can help companies achieve sustainability objectives by reducing their carbon footprint from raw material extraction, product design, manufacturing, transport, through life. At the heart of a company’s sustainability effort is the ability to reduce the three categories of GHG emissions as outlined by the Greenhouse Gas Protocol. Scope 1 are “direct” emissions―those that a company causes by operating things it controls, such as running machinery to make products at their own manufacturing site. Scope 2 are “indirect” emissions―those created by the energy an organization buys. The most difficult, scope 3, are “indirect” emissions―those not produced by the company itself, but by customers and suppliers in their upstream and downstream value chain. This often accounts for over 70% of a business’s carbon footprint.[10] Of the three, scope 2 is the easiest to solve as companies can source renewable energy as opposed to buying electricity generated using fossil fuels. A company needs to focus both on reducing the carbon footprint of the business and its PCF, which is a measure of GHG emissions caused by a product across its entire lifecycle. Within a PCF, we focus on “embodied” (embedded) carbon―the GHG emissions from manufacturing, construction, transportation, installation, maintenance, and disposal of materials.

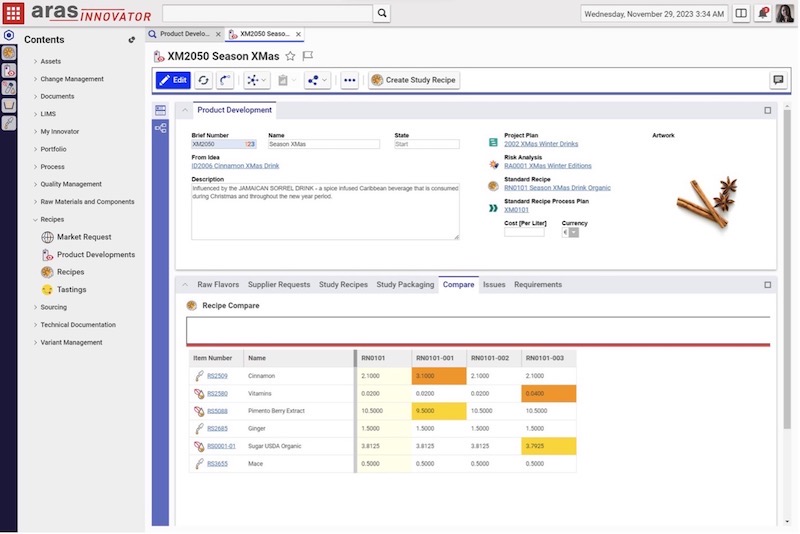

Since each GHG has a different warming potential and stays in the atmosphere for different periods of time, each is given a global warming potential (GWP) so we can measure all embodied carbon with a common measurement equivalent to CO2 known as a carbon dioxide equivalent (CO2e). Aras can track CO2e for parts and materials. It can also enable sustainability trade-off analysis using that CO2 data. Aras Innovator’s open platform enables an ecosystem to enrich and complement internal data with a partner’s data (see Figure 1).

Figure 1―Recipe Comparison in Aras Innovator

(Courtesy of Aras)

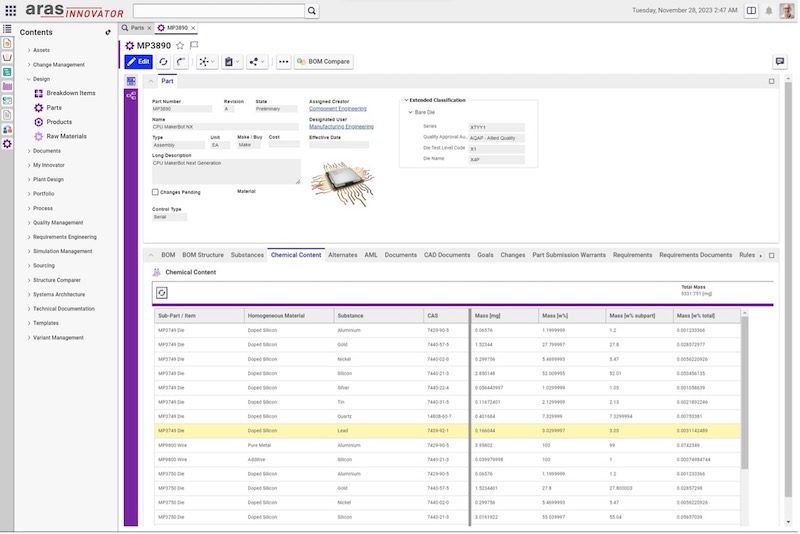

Aras Innovator is an application platform for managing complex engineered products that includes many PLM applications built using the services from the platform. Due to the Aras platform’s flexible architecture, it can integrate proprietary and third-party applications such as Ansys Granta, which offers a comprehensive materials database. Aras can also integrate with sustainability-related material characteristics managed by third parties and suppliers. By placing sustainability attributes and processes within the Aras platform, Aras can help companies reduce their product carbon footprint from raw material extraction, through design, manufacturing transport, and continuing through life by keeping a running tally. (See Figure 2).

Figure 2―Chemical Content KPI Rollup in Aras Innovator

(Courtesy of Aras)

Aras can also use KPIs, to define appropriate indicators for a company’s industry, products, and services. These can be used as a useful measurement of sustainability across the product lifecycle.

The concept of systems thinking―a holistic approach to understanding complex interconnected systems―is an important concept for sustainable, smart, connected products that interact with the world around them. In many cases, these will involve digital (virtual) twins of the physical product in use and digital threads (webs) that connect end-to-end from the as-running products to the system models and many sources of data that support these assets. CIMdata believes that if you are building sustainable circular products, a platform that is open, configurable, and easily interoperable with a much broader ecosystem is needed to handle the complexity.

Aras’ platform can enable companies to design out waste. It permits them to design for sustainability, supporting constant reuse in continuous closed-loop cycles. Ideally, this allows organizations to strive for a model of production and consumption that involves repairing, refurbishing, and recycling materials and products for as long as possible and potentially leads to different models such Product-as-a-Service (PaaS). CIMdata believes companies will need to rethink their business models to adapt to the needs of a growing circular economy.

Designing for sustainability cannot take place without intensive collaboration with the value chain, where most of the PCFs embodied CO2e exists. This requires companies to take a more collaborative and strategic approach to how they collaborate between product engineering, sourcing, and strategic suppliers. Companies are no longer concerned with just low-cost, but more resilient, collaborative, and sustainable suppliers. Ensuring suppliers know the CO2e of what they design, or produce is key.

Aras provides a flexible supplier collaboration capability that enables companies to provide suppliers and partners with secure external access whether a company is empowering their supply chain to access data within their firewall or in a SaaS environment. Beyond role-based access, Aras provides two additional forms of access control: mandatory and domain. Mandatory access control restricts what a user has access to due to attribute-based rules assigned to the item. Domain access control is a form of relationship-based control that can limit access of users or groups to projects or stages, which limits what a supplier could have access to and when.

Due to the large amount of embodied carbon within the value chain, CIMdata believes what is now key is not just strong supplier collaboration between a company and their value chain but understanding the suppliers’ embodied CO2e and any other sustainability data required. The company must demonstrate transparency to showcase their commitment to sustainability and accountability. They must also clearly communicate the commitment to track CO2e emissions of supplied materials, parts, designs, and manufactured items, and how it aligns to their sustainability goals. The ease with which they can supply this data and whatever verification and validation will be used to ensure accuracy of the reported emissions and sustainability data needs to be understood upfront.

Conclusion

Companies are struggling to define and address their sustainability goals. CIMdata believes that the Aras platform provides the ability to manage the reduction of sustainability challenges, enabling companies with a flexible approach to transform to meet their business objectives both now and in the future. CIMdata’s view is that the Aras platform can help companies manage the processes for reducing their PCF from raw material extraction, design, manufacturing, transport, through life. While there is no single killer application on the market, the Aras platform can integrate best-of-breed solutions, which can be tailored and integrated via their low-code/no-code capabilities to ensure sustainability management fits a company’s needs. CIMdata believes that the Aras platform is well positioned to manage all types of sustainability data (e.g., CO2, substance, material, regulatory) across all aspects of the product lifecycle. This will be a critical factor in the growing circular economy. Designing for sustainability cannot take place without intensive collaboration with the extended value chain. Aras provides significant capability to collaborate with suppliers through life. CIMdata is encouraged by what we have seen. We look forward to seeing future sustainability enhancements to the platform and partnerships that will help Aras’ customers realize their sustainability goals.

[1] https://yaleclimateconnections.org/2023/03/with-global-warming-of-just-1-2c-why-has-the-weather-gotten-so-extreme/

[2] https://gml.noaa.gov/ccgg/trends/

[3] https://climate.nasa.gov/evidence/

[4] https://www.un.org/en/climatechange/net-zero-coalition

[5] Research for this commentary was partially supported by Aras.

[6] https://www.reuters.com/markets/us/how-2021-became-year-esg-investing-2021-12-23/

[7] https://www.pwc.com/us/en/services/governance-insights-center/library/annual-corporate-directors-survey.html

[8] hbr.org/2022/08/why-companies-arent-living-up-to-their-climate-pledges#:~:text=An%20Array%20of%20Hurdles&text=Thirty-three%20percent%20reported%20that,clear%20decision-making%20and%20accountability

[9] https://www.cimdata.com/images/Webinars/CIMdata_Webinar_27_April_2023.pdf

[10] https://www.weforum.org/agenda/2022/09/scope-emisRsRecipeions-climate-greenhouse-business/